LT-2320

16

SERVICE

CPAP SERVICING AND PARTS

REPLACEMENT

Tools and Equipment Needed:

• T-10 Torx driver

• Needle nose pliers

• Digital Multimeter for measuring AC/DC voltages and resistance

• AC power source (100 to 240 VAC 50/60 Hz)

Inspecting Internal Components

When servicing or troubleshooting the CPAP, it may be necessary to

closely inspect all of the internal components in order to determine the

cause of the problem or issue. The following steps are provided as a

guide to assist you when performing a detailed inspection or

evaluation of the CPAP.

During service, do not touch the contacts at the end of the ribbon

connector/cable. Grease or oil from your ngers will render the display

inoperative.

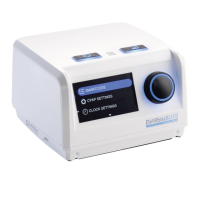

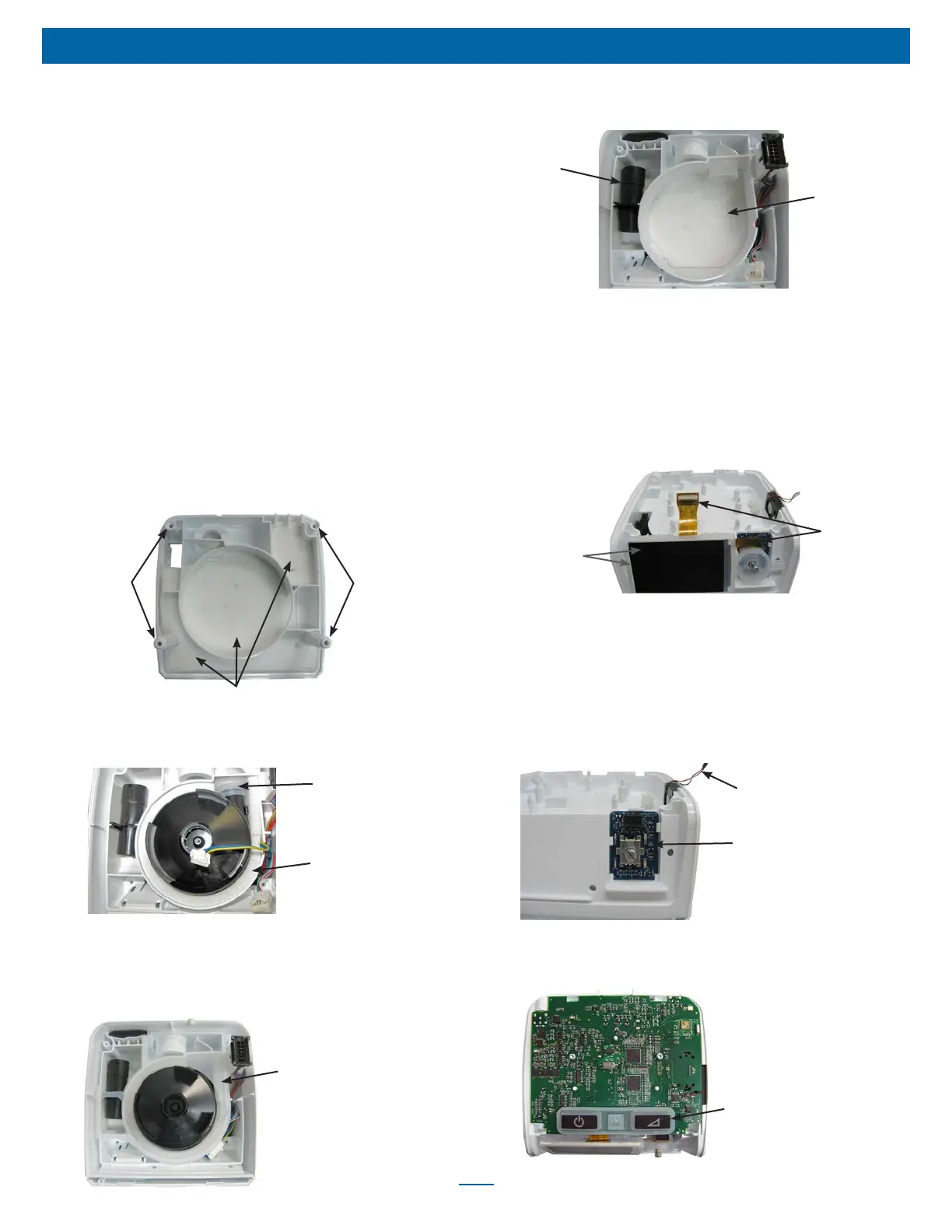

Inspecting components in and on the blower

chassis:

1. Remove bottom cover using instructions listed on pg. 17.

2. Inspect the bottom cover foam pieces and mounting bosses for

damage. Replace as needed.

Mounting

Bosses

Mounting

Bosses

Foam

3. Remove blower. See ‘to remove and replace blower’ section.

4. Inspect the blower foam pieces and the blower discharge isolator.

Ensure they are not damaged. Replace as needed.

Blower Isolator

Blower Isolation

Foam

5. Look for evidence of water residue inside the blower housing.

6. Verify that the blower halves are properly snapped together. No

visible gap should be present between the top and bottom

sections. Also inspect the chassis manifold for any damage.

Replace if necessary.

Chassis Manifold

7. Make sure the ow element is positioned properly and not dirty or

damaged.

Flow

Element

Top Blower

Foam

8. Replace blower. See ‘to remove and replace blower’ section.

Inspecting components in and on top of the

main chassis:

1. Remove top cover using instructions listed on pg. 17.

2. Remove PC board. See instructions ‘to remove and replace PC

board’ section.

3. Inspect the LCD display mounting to the front of the chassis and

ensure that it is positioned correctly.

Ribbon

Connectors

LCD Display

& Mount

Isolator

4. Closely inspect both ribbon connectors. Make sure there are no

breaks or nicks in the wire insulation. Also be sure the smaller

ribbon connector is securely attached to the Encoder PC board.

NOTE: During service, do not touch the contacts at the end of

the ribbon connector/cable. Grease or oil from your ngers will

render the display inoperative.

5. Inspect the Encoder PC board for any broken connections

around the stem that the rotary knob plugs onto.

Speaker Wires

Encoder PC Board

6. Inspect the speaker for any broken wires.

7. Remove the keypad from the PC board by gently pulling upward

until the ‘rat tails’ are out of the holes.

Keypad

Loading...

Loading...