27

MACHINEPREPARATION(Continued…)

4. TurnthebandtensionselectortoONandthento

HOLDuntilthesawbandistensionedjustenough

tobeheldinplaceandadjustmentscanbemade.

5. Check the saw band portion around both band

wheelsandadjust(itsbackmustrestagainsteach

wheel’srearflange.Whensatisfiedthatsawband

positioning is correct: (a) turn the band tension

selectortoON;(b)movethesawguidearmtothe

desiredposition;(c)tightenbothsaw guideinsert

adjustmentscrews.

6. Reposition the band brush and tighten the clamp

handle (brush bristles should clean the teeth tips

butnocontactthebottomofthegullets).Then:(a)

liftthebandwheeldoorstodisengagethelockand

closebothdoors;(b)jogthebanddrivemotor;(c)

openeachbandwheeldoortomakesurethesaw

bandisagainstthebandwheelflanges(+/‐1mm);

(d)closethedoorswheneverythingissatisfactory.

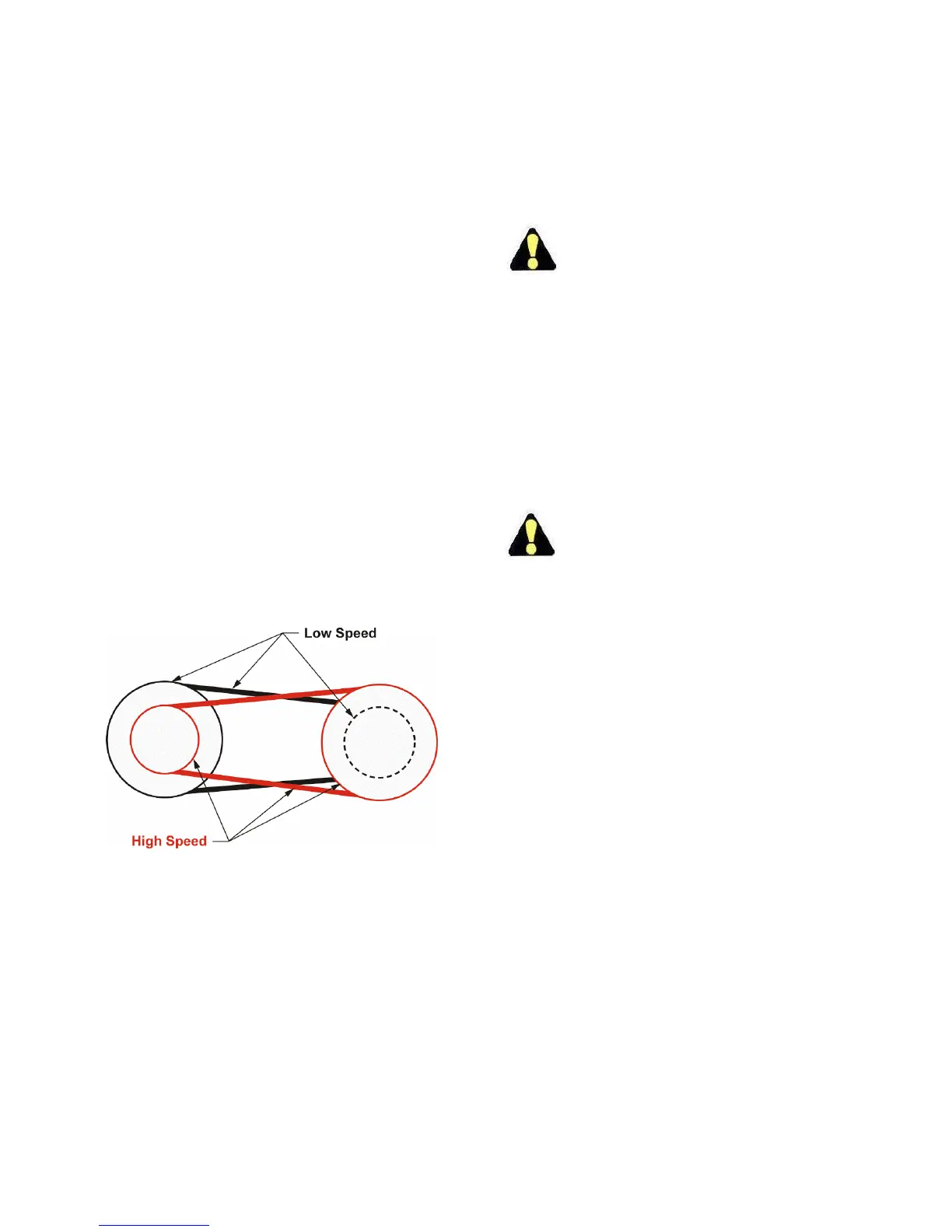

BANDSPEEDRANGE

1. The operator can select between HIGH and LOW

bandspeedrangesbyswitchingthedrivebeltfrom

onesetofpulleystotheother.

2. LOWrangeisthefrontsetofpulleysandHIGH

rangeistherearset.

BandSpeedRangePulleys

3. Bandspeedrangeisasfollows:

LOW: 15–85m/min

HIGH: 25–135m/min

4. To change the band speed range, open the right band

wheeldoor.Then:(a)undotheguardclipandremovethe

screws;(b)locatedintherearofthemachinebetween

thebanddrivemotorandthegearbox,turnthe

adjustmentknobcounterclockwisetorelaxbelttension;

(c) install the belt to the desired speed range set of

pulleys.

5. Turntheadjustmentknobclockwisetotensionthebelt.

Thereshouldbeverylittledifferenceatthecenterspan

ofthebelt.

6. Flip the cover up and engage the clip and install the

screws.

LEFTSAWGUIDEARMADJUSTMENT

Therightsawguidearmcannotbeadjusted.

1. Theleftsawguidearmmovesalongtheslidebarto

accommodate various stock widths(the arm shouldbe

positionedascloseaspossibletotheclampedstock.

2. Stockwidthsettingsaredepictedbyaslidebarscalewith

bothmetricandinchmeasurements.

3. Toadjusttheleftsawguidearmaccordingtostockwidth,

theoperatorloosenstheleftinsertadjustmentscrewand

theguidearmlockinghandle.Next:(a)lineuptheleftsaw

guidearm’srightedgewiththeproperinscribedscaleline;

(b)securethesawguidearminthechosenlocationby

tighteningtheguidearmhandle;(c)tightentheleftinsert

adjustmentscrew.

DONOThammerthelockinghandwheel.Hand

tighteningisadequatetolocktheleftsawguidearm

inplace.

FEEDFORCEADJUSTMENT

1. Feed force is the pressure exerted by the workpiece

against the saw band’s cutting edge. It is controlled

hydraulically and regulated with the Feed Forcevalve.

TurnthevalveclockwisetoDECREASEpressure,

counterclockwisetoINCREASEpressure.

2. Thefollowingareimportantfactorstoconsiderwhen

settingoradjustingtheFeedForcevalve:

TurntheFeedForcevalvetoalowsettingifthe

correctfeedforceisnotknown.Theoperator

canthenincreaseordecreasepressureduring

operation to obtain the best cutting rate

consistentwithdesiredbladelifeandcutfinish.

Alwaysbesuretotakeagoodchip.

NeverstartacutwiththemaximumFeedForce

valvesetting.Bladedamagemayoccur.

Certainwork‐hardeningmaterialswillrequirea

moderate to heavy initial Feed Force valve

setting to assure immediate penetration of

bladeteeth.Lightfeedsonthesematerialsmay

causethebladetoslideoverthestockresulting

insawbanddamage.

Loading...

Loading...