36

BANDDRIVEGEARBOX

1. Gearbox replacement, repair, adjustment or

alignment should be performed only by a DoALL

servicerepresentative.

2. Themachine’sgearboxreservoircapacitydepends

onmachinemodel.Checkthereservoiroildailyby

referringtothesidegauge.

3. Beforechangingthegearboxoil,lowerthesaw

headcompletelyandstopthehydraulics:(a)place

a container under the gearbox; (b) remove the

reservoirdrainplug;(c)allowthereservoirtodrain

completely;(d)removethetubebreatheratthetop

of the gearbox; (e)replace the drain plug making

sureitistightandsealed.

4. Fillthegearboxwithoilthroughthetubebreather

opening until it is above the red line on the side

gauge.

5. Change the oil after the first three months of

operationandtheneverysixmonthsthereafter.

MACHINECLEANING

1. Keepthemachineanditspartascleanaspossible

topreventexcessivewearordamage.

2. Usetheflushinghoseassoonaspossibletoremove

metalchipsand otherwastematerials whichmay

collectaroundthesawguides,bandwheels,vises,

slides, sensing arm, etc. The hose has a hand

operatedvalveandattachestothecoolantpump

The DoALL Company recommends using the

flushinghosetoremovechipsatleasttwiceper8‐

hourshift,andmoreoftenwithheavieruse.

3. Useashovel,scooporraketoremoveaccumulated

metal chips or other waste materials from the

machine areas. Be sure the band drive motor is

stoppedbeforecleaning.

MACHINEALIGNMENT

1. Misalignment of the machine’s saw guide arms,

slidebar,sawband,pivotpoints,gearbox,etc.will

causeinaccuratesawing.

DONOTattemptanyalignmentprocedures

not covered by this manual. Contact a

DoALL service representative in such case

because special fixtures and techniques may be

required.

BANDBRUSH

1. Thebandchipbrushwillwearandlosesteelbristles

overtime.Checkoftentobesurethebristlesare

removingmetalchipsfromthetoothtips,butare

nottouchingthebottomofthegullets.

2. Movethebrushclosertothebladeasnormalwear

occurs.Replacethebrusheswhennecessary.

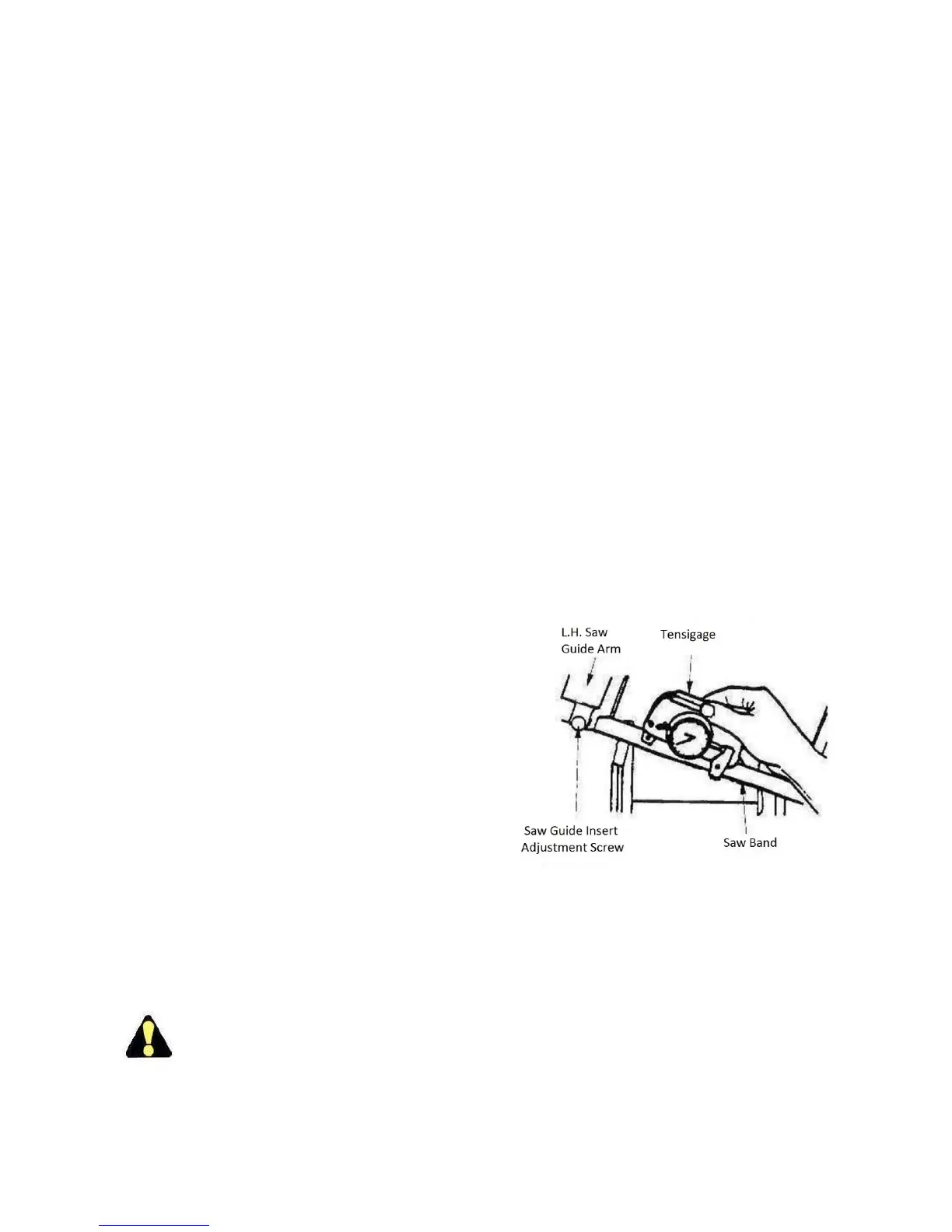

BANDTENSIONMEASUREMENT

1. Bandtensionisfactoryset.

Bandtensionmeasurementcanbemadewith

the hydraulics running and by using a DoALL

Tensigage.

2. Tensionmaybe checked“readingup” or“reading

down”.Toreadup:(a)fixthetensigagetoaslack

sawband;(b)applytension.Toreaddown:(a)fix

the tensigage to a tensioned saw band; (b) relax

tension.

3. AcorrectDoALLtensigagereadingdependsonthe

machine model. See the machine specification

chart.

UsingaTensigagetomeasurebandtension.

WEARPLATEREPLACEMENT

1. Theremovablevisejawandviseguidebarsmustbe

replaced before excessive wear causes the

mounting screw heads to become damaged and

makesremovaldifficult.

Loading...

Loading...