35

MAINTENANCE

REPLACINGSAWGUIDEANDBACK‐UPINSERTS

These instructions can be used to replace

thesawguideinsertsandback‐uprollersor

insertsonbothsawguidearms.

ThebanddrivemotormustNOTberunning

when replacing saw guide and back‐up

insertsorrollers.

1. Loosentheinsertadjustmentscrewoneachsaw

guidearm.Then:(a)removetheleftsawband

guard (if necessary); (b) remove the adjustment

screw being very careful not to drop or lose the

insert,screwandwashers;(c)loosenthesocketcap

screwfromtherearsideofthesawguidearmsand

removetherearinserts.

2. Thoroughlycleanthesawguidearmandinserts

area.Then:(a)checktheback‐uprollersorinserts

forwearandreplacetheminneeded.

3. Installthenewfixedinsertandtightenthe screw.

Then: (a) thread the adjusting screw inward part

way;(b)installtheadjustableinsert;(c)tightenthe

adjustment screw; (d) replace the left saw band

guard(ifremoved).

BANDDRIVE/BRUSHBELTREPLACEMENT

1. Tochangethebanddrivebelt,opentherightband

wheel door. Then: (a) undo the guard clip and

removethescrews;(b)locatedintherearofthe

machine between the band drive motor and the

gearbox,turnadjustmentknobcounterclockwiseto

relaxbelttension;(c)removetheoldbeltandinstall

thenewbeltbystretchingthebeltoverthedesired

speedrangesetofpulley’s.

2. Turnadjustmentknobclockwisetotensionthebelt.

Thereshouldbeverylittledeflectionatthecenter

spanofthebelt.

3. Flipthecoverbackupandengagetheclipand

installthescrews.

HYDRAULICSYSTEM

1. Themachine’shydraulicreservoircapacitydepends

on machine model. Check the oil level daily by

referringtothesidegaugelocatedontheleftside

ofthemachinebehindthecontrolconsole.

2. Beforechangingthehydraulicoil:(a)lowerthesaw

headcompletely;(b)pushthehydraulicstopbutton;

(c)placeacontainerofsufficientcapacityunderthe

drainport;(d)removethedrainplug;(e)allowthe

reservoirtodraincompletely.

3. Drain,cleanandrefillthereservoir.Changeoilafter

the first three months, and every six months

thereafter. Clean the suction strainer and filter

opening screen when necessary. Use high quality

hydraulicoil,typeISO‐VG46.

Systempressure

1. Hydraulic system pressure is correctly set at the

factoryandshouldnotrequireadjustmentfora

considerableperiodoftime.

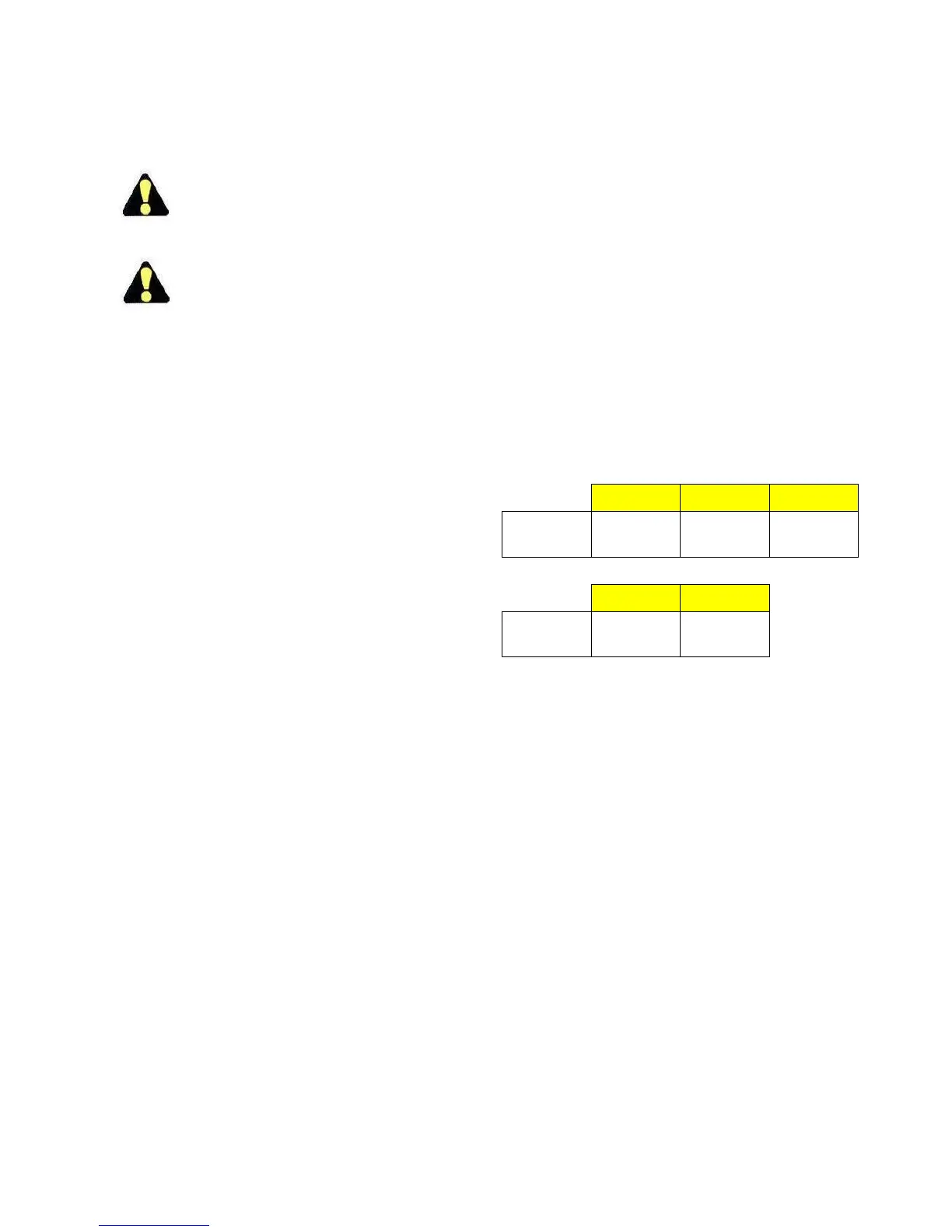

C‐3028NC C‐4033NC C‐420NC

System

pressure

30bar 30bar 40bar

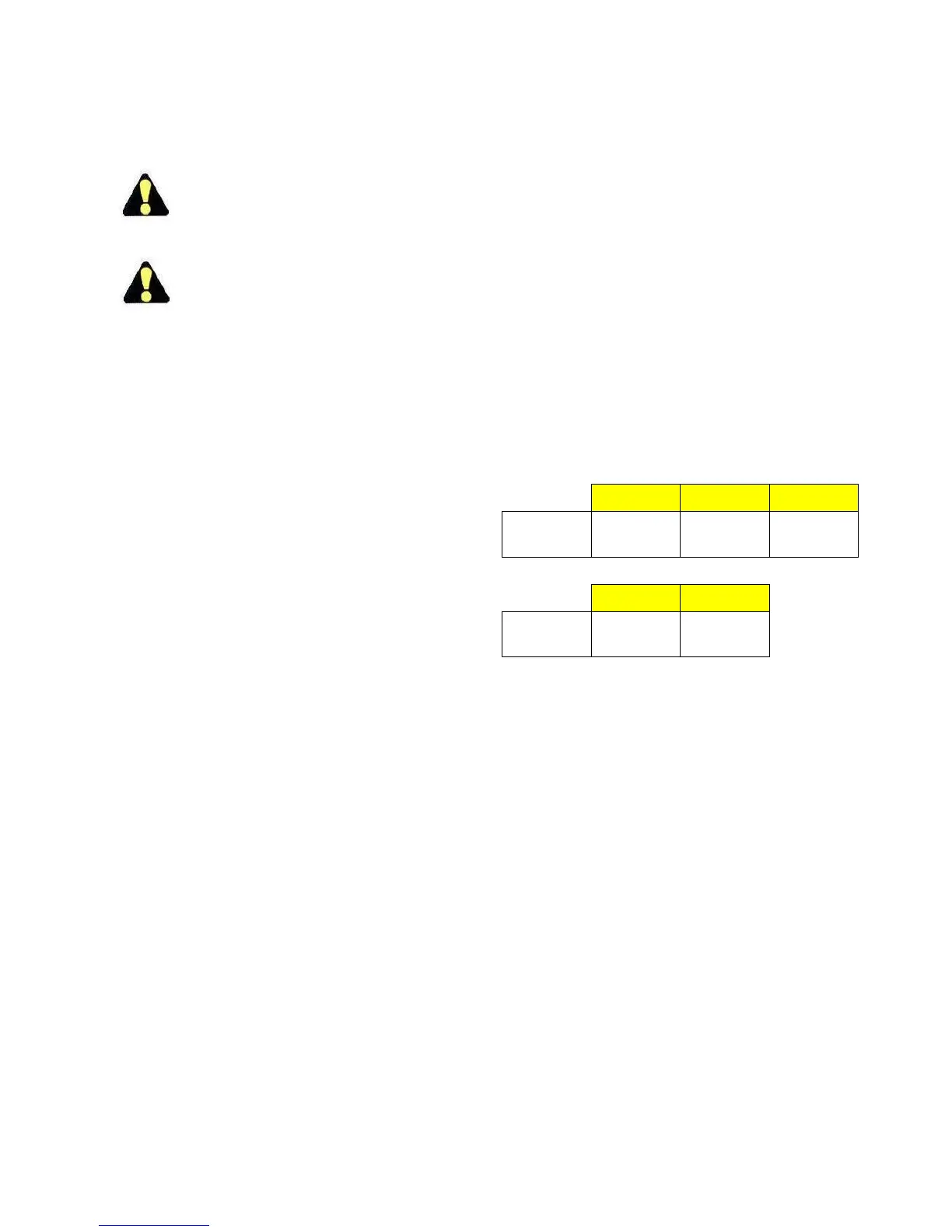

C‐5650NC C‐560NC

System

pressure

40bar 45bar

COOLANTSYSTEM

1. Themachine’s coolantreservoir capacitydepends

onmachinemodel.Areservoirlevelsightgaugeis

locatedatthemachine’srightfrontside.

2. Checkthecoolantoftenforsignsofcontamination

or breakdown. The reservoir and coolant system

should be drained and cleaned thoroughly when

thecuttingfluidbecomesundesirableforfurther

use. If another type of coolant is to be used, the

entire system must be flushed using DoALL Kleen

Flush.

3. Tothoroughlycleanthereservoirsectionbelowthe

conveyor trough, removal of the trough will be

necessary.

4. Fillthereservoirwithcoolantthroughtheconveyor

screwuntiltheredmarkinglineinthesidegauge.

Loading...

Loading...