28

FEEDFORCEADJUSTMENTS(Continued…)

Generally, top performance from a sharp saw band

resultsfromrelativelylowFeedForcevalvesettings.

Itwillbenecessarytoincreasethesettingasthesaw

bandbecomesduller.Thiswillkeepthecuttingrate

constantthroughoutthelifeofthesawband.

Feedforceadjustmentsarenotnecessaryfor

changing stock cross‐sections. A balancing valve

enablesthesawbandtomaintainauniformcutting

rate.

Reducingcuttingrateandbandspeedforpipe,tubing

andstructural.

1. Increasing loading per tooth occurs when sawing

thin stock sections. Although the blade can bear

someoverloading,acuttingratereductionmustbe

made.

2. Whenitbecomesnecessarytomodifysolidsection

sawingrecommendations:(a)measurethethinnest

sectiontobecut;(b)applyapercentagefactorof

40%forthinmaterialto70%formaterialswitha

wallover25mm;(c)useahighbandspeed,but

never exceed the maximum speed recommended

onthechartfoundatthebeginningofthe

OPERATIONchapterforstockofthesamesize.

FEEDRATE

1. Correct feed rate is important for helping: (a)

determineoverallcuttingaccuracyandfinishofcut;

(b)improvebladelifebyeliminatingbreakageand

tooth stripping at the cut’s start and break‐out

points.

HEADELEVATIONANDSENSINGARM

Headelevation

1. Sawheadelevationduringautomaticsawingcycle

is initiated when the head down limit switch is

actuated. The saw head then rises to a height

determinedbyasensingarm.

2. Afteracuthasbeenmadeinthemanualoperating

mode,the actuatedhead downlimit switchstops

machine operation. To lift the head off the limit

switchandresumeoperation,theoperatormust:(a)

pushandholdthesawheadupbutton.

Sensingarm

1. Thesensingarmworksinconjunctionwiththehead

clearlimitswitchtoassurethesawheadisraised

sufficientlyaboveexistingstocksothatautomatic

indexing or manual stock positioning can be

accomplishedsafely.

Sensingarmoperationwhenthesawheadrises

1. Thesawheadliftsthesensingarmabovethestock

atarapidrate(thereisnoslowheadraisingrate)

until it actuates the head clear limit switch. This

causes saw head upward movement to stop the

bladeapproximately25mm above thestock.This

clearanceanticipatespotentiallycrookedoroutof

roundstockbeingused.

2. Ifoperatinginautomaticmode,thefixedvisethen

unclamps, the index vise clamps, and stock is

indexed forward. Following the advance of stock,

thefixedviseclampsandtheindexviseunclamps.

3. Whenthefixedviseunclampspriortoindexing,its

jawopensjustenoughtoallowstockadvancement.

Thevisejawscanbeopenedwideronlywhenthe

sawheadhasbeenmanuallyraisedabovethejaws.

Thispreventsdamagetojawsorsawguidearm

whenfullyopeninginalowerposition.

Leftsawguidearmadjustmentforstockwidth

mustbemademanuallybytheoperator.

Sensingarmoperationwhenthesawheadlowers

1. Thesawheadlowersattherapidapproachrate

untilstockiscontactedbythesensingarm.Afeed

rateisthenestablishedandcuttingbegins.

2. Sensing armcontact with thestock inmaintained

throughoutthecut.Afteracuthasbeenfinished:

(a)theheaddownlimitswitchisactuated;(b)the

sawheadrises.

MINIMUMBAREND

1. Whentheindexingviseiscompletelyforward,both

ofitsvisejawsextendtowardsthefrontvisejaws.

Thisextension,togetherwiththenestingdesignof

thevises,permitsautomaticindexingofstockuntil

asmallbut‐endremains.

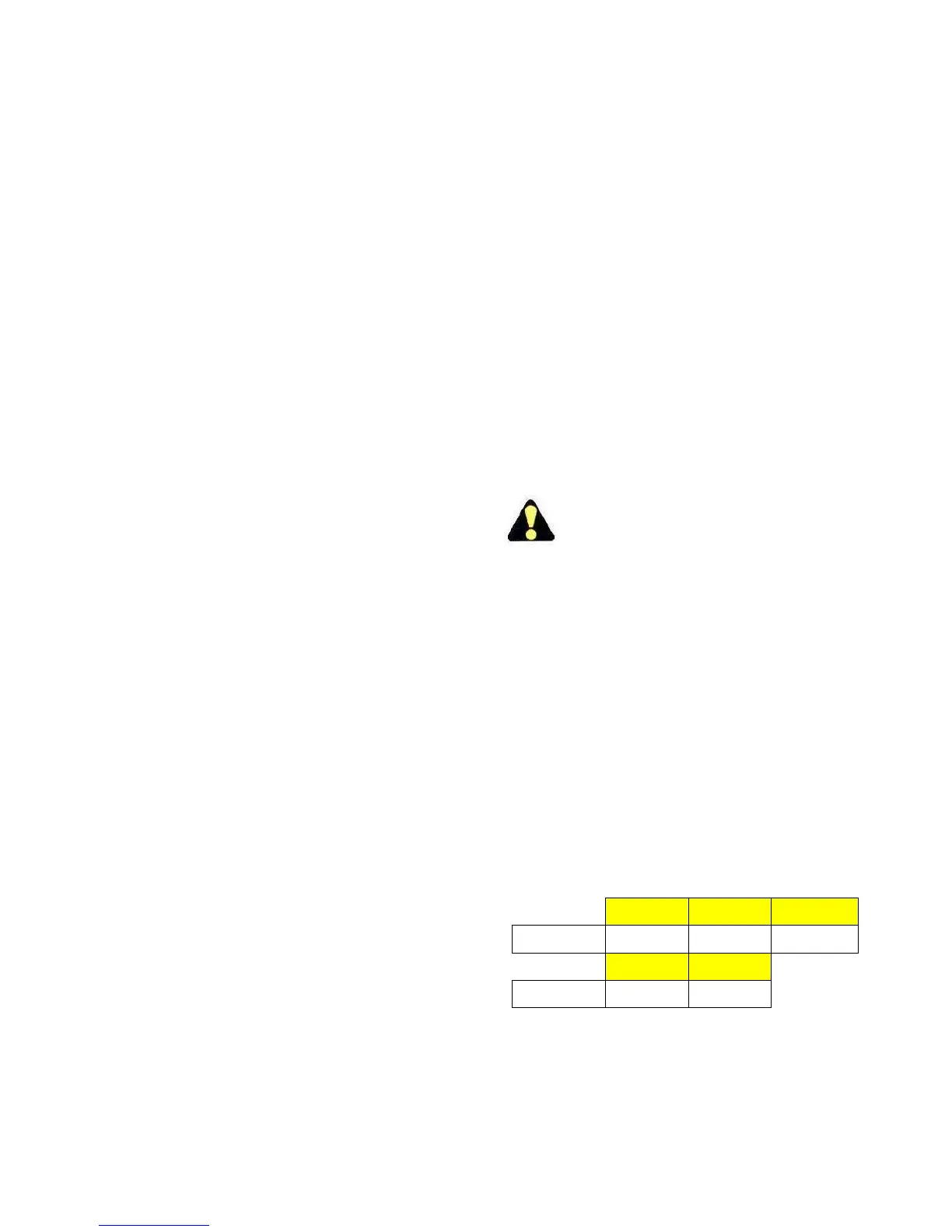

C‐3028NC C‐4033NC C‐420NC

Min.barend 95mm 110mm 110mm

C‐5650NC C‐560NC

Min.barend 115mm 155mm

2. If the stock is shorter, it will not be stable in the

indexvise.

Loading...

Loading...