29

VERTICALGUIDEROLLERS

1. Theserollersaremountedneartheendofthe

indextableandprovidestwolaterallyvertical

rollers.

2. Whentheverticalrollerisnotneeded,itcanbe

swiveledinthedownposition.

HYDRAULICSYSTEM

1. The hydraulic and band drive systems operate

independently.Thisallowstheoperatortoperform

following tasks while the banddrive motor is not

running: (a) change saw bands; (b)raise or lower

the saw head; (c) clamp or unclamp vises; (d)

positionstockmanually.

2. Themachine’shydraulicreservoircapacitydepends

onthemachinemodel(seemachinespecifications

chart). Refer to the lubrication section of this

manualforrecommendedoils.

COOLANTSYSTEM

Coolantselection

1. The main cause of tooth failure during band

machining is excessive heat built‐up. Using the

propercuttingfluidreducestheheatgenerated

during operation. It also helps the machine take

fulladvantageofitshigh‐speedsteelsawbands.

Coolantapplication

Literaturedescribingtheseandother coolant

types are available from your DoALL sales

representative.

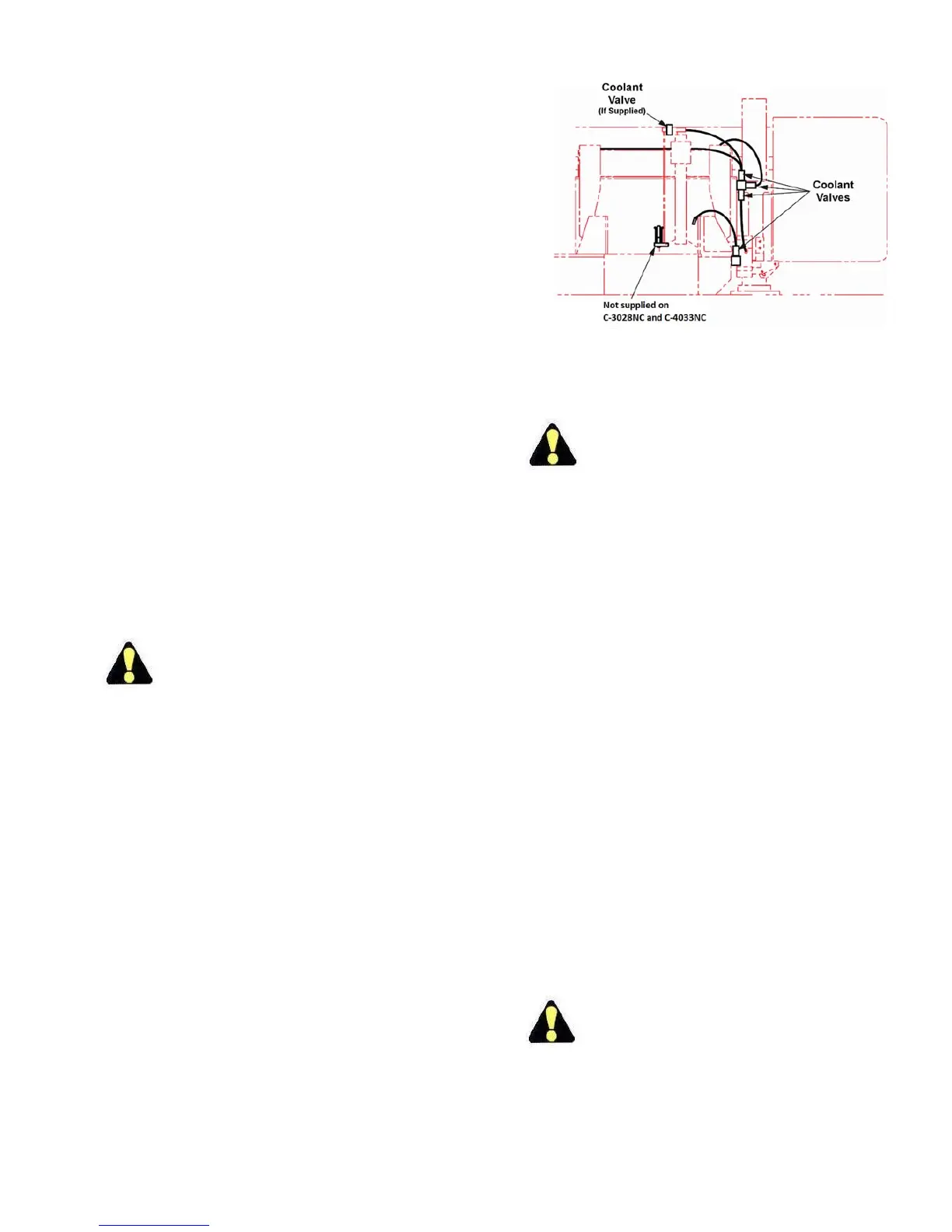

1. Coolantisappliedasfollowsduringsawing:

Tothesawbandandcuttingareathroughthe

sawguideinserts.Flowisregulatedbyavalve

oneachsawguidearm.

To the band brush cleaning area through a

flushingnozzle.Flowiscontrolledbyavalve.

Tothecuttingareathroughaflushingnozzle.

Flowiscontrolledbyavalve.

Anadditionalflexibleflushingnozzlecanapply

fluidwhereneeded.Controlledbyavalve.

2. Coolantflowisstartedby:(a)pushingthehydraulic

startbutton;(b)turningthecoolantselectorto“I”

or“AUTO”;(c)turallthecoolantvalvesonuntil

fluidscompletelyshroudsthesawband.

3. Checkthecoolantreservoirlevelifflowisstopped

orreduced.Reservoircapacitydependsonmachine

model.Acoolantlevelsightgaugeislocatedatthe

frontrightbottomofthemachinebase.

Coolantapplicationpoints.

Coolantapplicationpoints.

CHIPREMOVAL

DONOTshovelorrakechipswhilethe

sawbandisrunning.

1. Metalchipsshouldberemovedfromtheworkarea

assoonaspossible.Theycanbewashedorscraped

intothechipconveyortrough.

Bandbrush

1. Acovered,banddrivemotordrivenbandbrushis

located near the right saw guide arm. During

machine operation, the brush bristles should be

positionedsothatthetipscleanchipsfromthe

teethtips,butshouldnotcontactthebottomofthe

gullets.DONOTallowmetalchipstoaccumulateon

thebrush.

2. Asthebristleswear,movethebrushclosertothe

blade.Todoso:(a)opentherightwheelcover;(b)

loosentheclampinghandle;(c)positionthebrush

forcorrectbladecleaning;(d)tightentheclamp

handleandclosethewheeldoor.

Flushinghose

1. Metalchipsandotherdebrismayaccumulateover

timearoundsuchareasas:sawguides,bothband

wheels,vise,slide,brushhousing,headliftcylinder,

feedanddischargeareas,etc.

2. The operator should check often for these

collectionswhichcanaffectmachineperformance.

Theyshouldberemovedwiththeflushinghoseas

soonaspossible.

TheDoALLCompanyrecommendsusingthe

flushinghosetoremovechipsatleasttwice

per eight‐hour shift, and more often with

heavieruse.

Loading...

Loading...