30

CHIPREMOVAL(Continued…)

Chipconveyor

1. During operation, metal chips and used coolant

drop directly into a sloped trough, or flow into it

fromthemachine’srun‐offsurfaces.Coolantthen

flows down the trough and through a filtering

screenbeforereturningtothereservoir.

2. Thechipconveyormotoroperatessimultaneously

with the hydraulic pump motor. The conveyor

augerrotatesslowlyatthebottomofthetrough.

It’smovementcarriesmetalchipstotheopeningat

themachine’srightsidewherechipsemptyintoa

customersuppliedcontainer.

3. Aneedlevalvelocatedbelowtheaugerallowsthe

chipaugermotortobeadjustedforfasterorslower

operation.

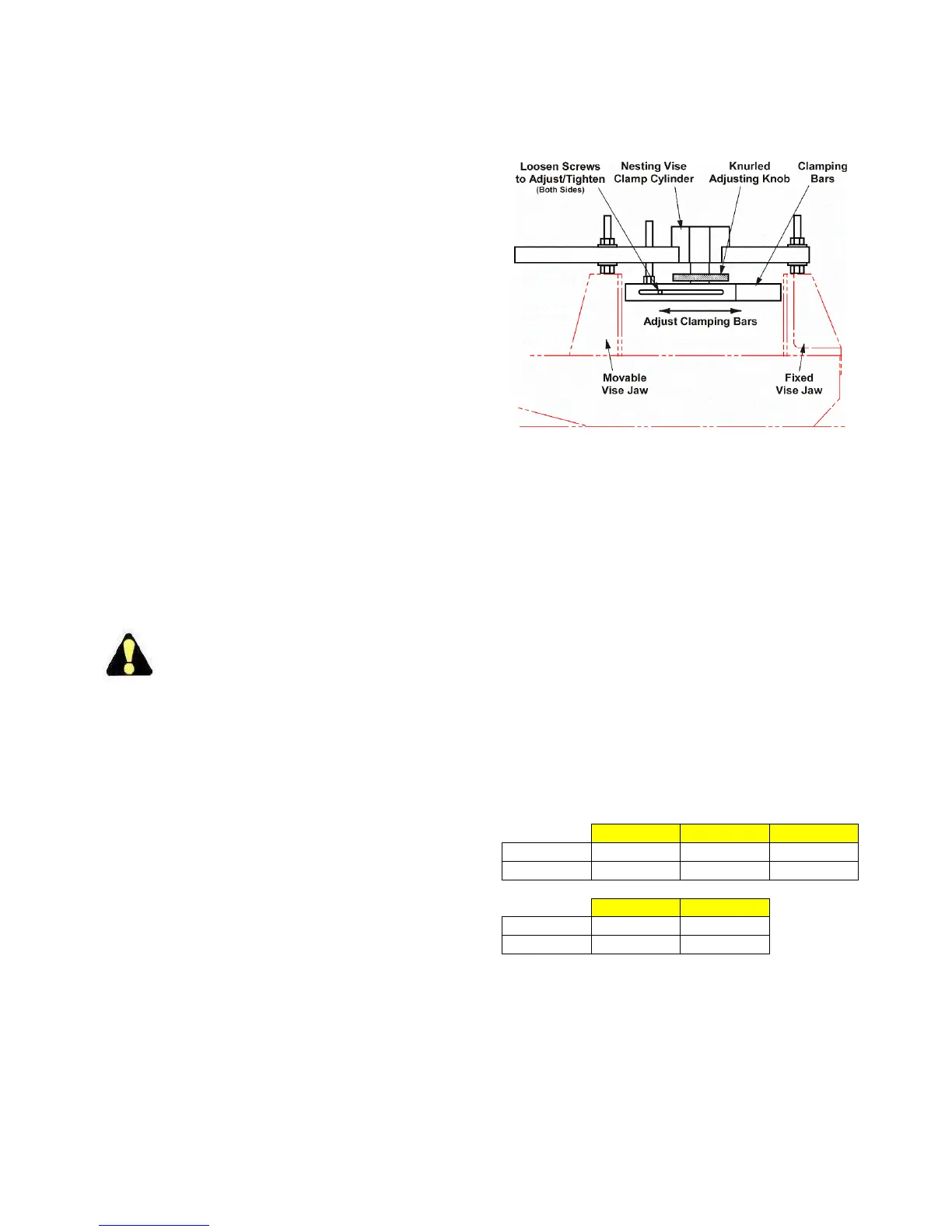

NESTINGFIXTURE

1. This feature is designed for high‐production,

multiplesawingofstackedbars,roundsandtubing.

2. Verticalnestingclampcylindersaremountedtothe

machine’s fixed and index vises. The cylinders

operate simultaneously with the regular vise

clampingcylinders.

3. Visecapacitydependsonthemachinemodel.

Thehydraulicoperatednestingfixturecanalso

beusedwiththevariablevisepressurecontrol.

Stackingstock

1. Correct stock nesting is essential for proper

clamping of the vises and nesting fixture. It is

important that nesting vise clamping pressure be

transmittedtoeverystackedpiece.Sometimesthis

can be more easily accomplished by manually

joggingthestack.

2. Properstackingofroundstockisimportantbecause

saw band breakage may occur if round nested

piecessliporspinduringsawing.

3. There are two (2) workable round stock stacking

methods,eitherinequalrows(4x4x4)ornested

rows(4x3x4).Thefirstprovidesthebestsawing

results,althoughthesecondmethodcanbeused(if

the material is not stacked too high) and offers

betterclampingwhenmaterialhassmalldiameter

differences.

4. Pieces should be stacked as closely together as

possible. Metal chips lodged in the open spaces

betweenindividualpieces willaffectcuttingaccu‐

racy.

Viseadjustment

Nestingfixtureviseadjustments.

1. Stack stockto be cutbetween the machine’s vise

jaws.Then:(a)openthefixedandrearvises;(b)bolt

thesupportingbartightlytothefixedvisejaws,but

looseonthemovablejaws.

2. Loosenthescrewoneachsideoftheclampbars

and position the clamp bars to fit the size of the

nestedstock.Thenadjusttheindextable’svertical

guide rollers so the stock will be guided correctly

towardthesawband.

3. The indexing vise has two positions to place the

nestingfixture.

PositionAistheforwardpositionontheindex

vise.

Position B is the rear position of the nesting

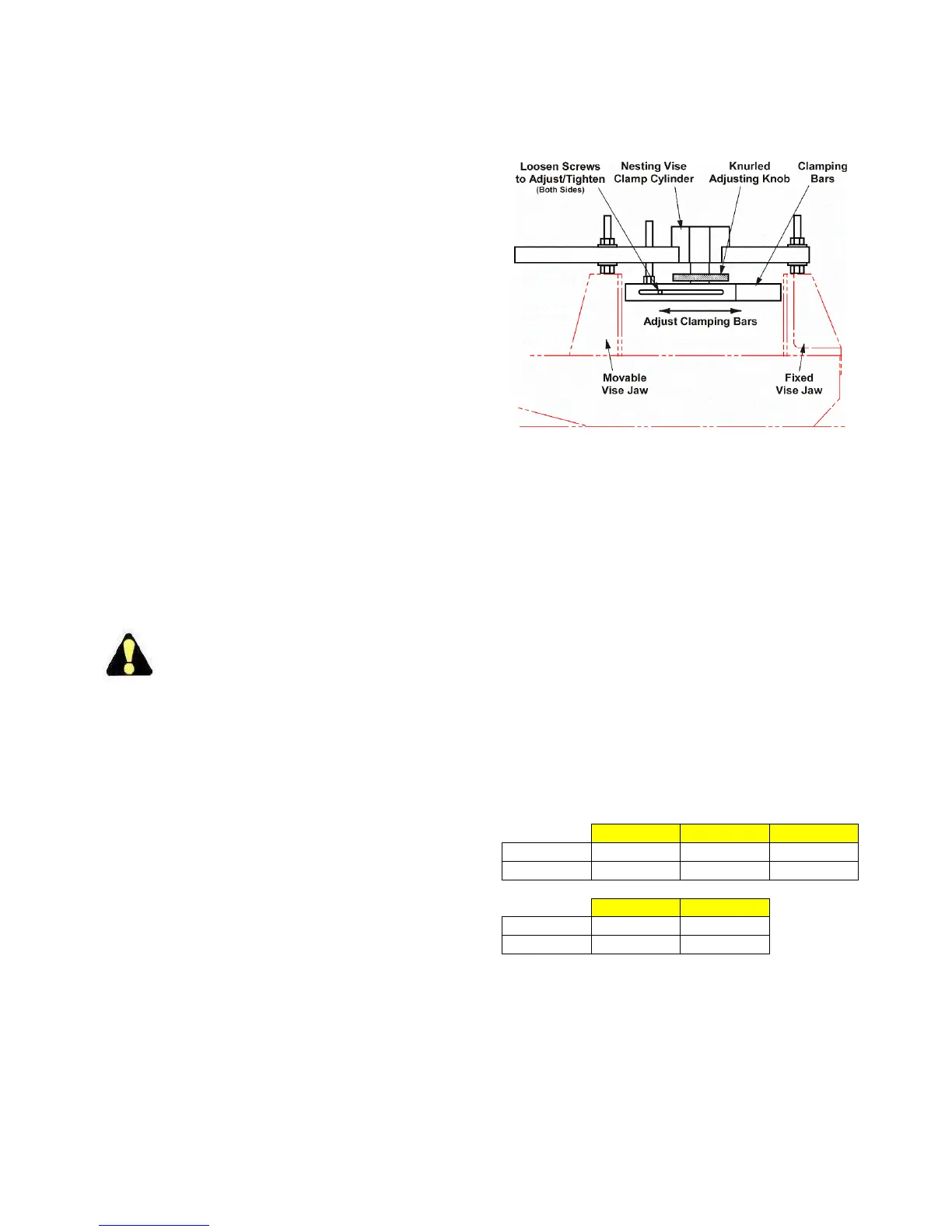

fixture.Seethechartbelow.

4. Theremnantwillchangedependingontheposition

ofthenestingfixture.Seethechartbelow:

C‐3028NC C‐4033NC C‐420NC

PositionA 190 200 215

PositionB 330 330 330

C‐5650NC C‐560NC

PositionA 215 N/A

PositionB 375 N/A

Loading...

Loading...