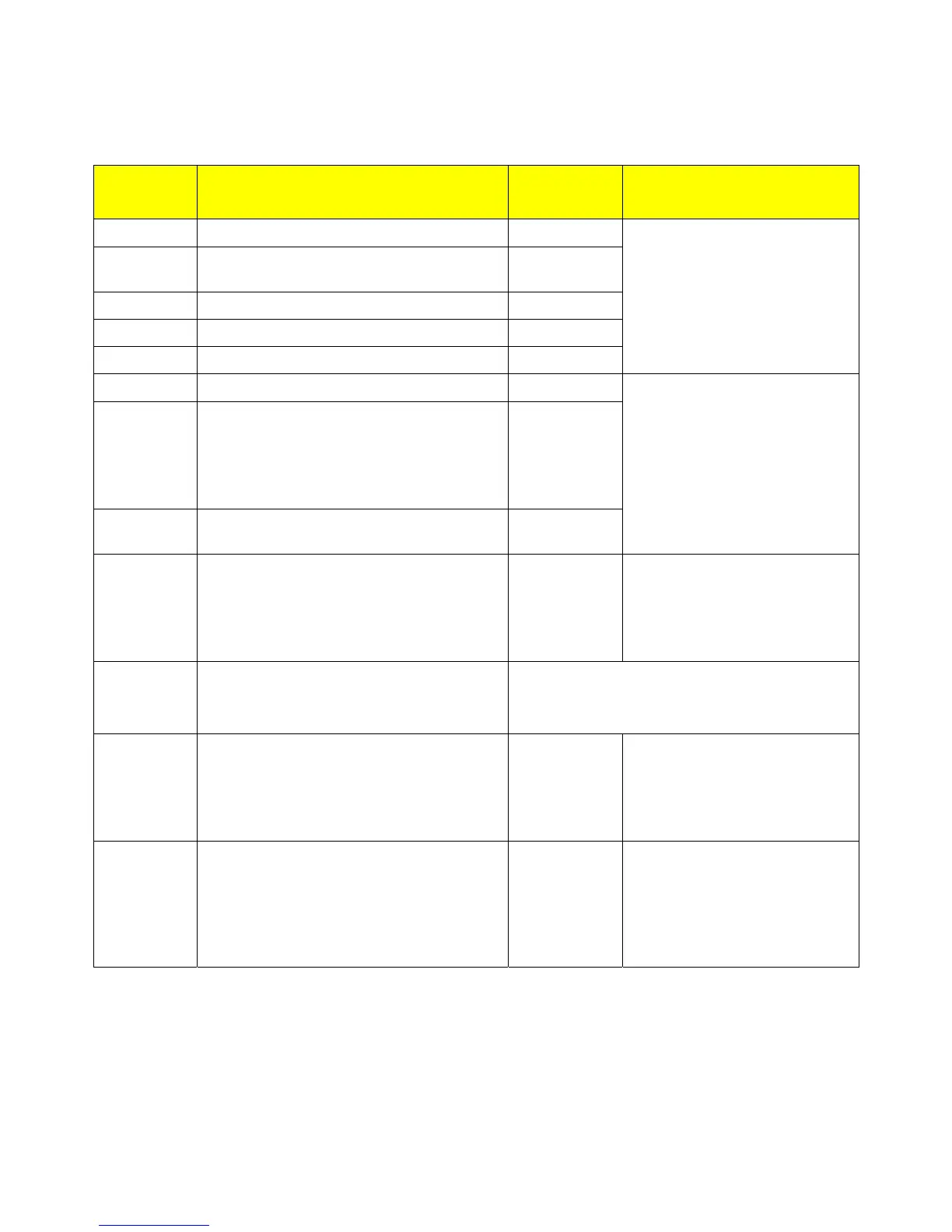

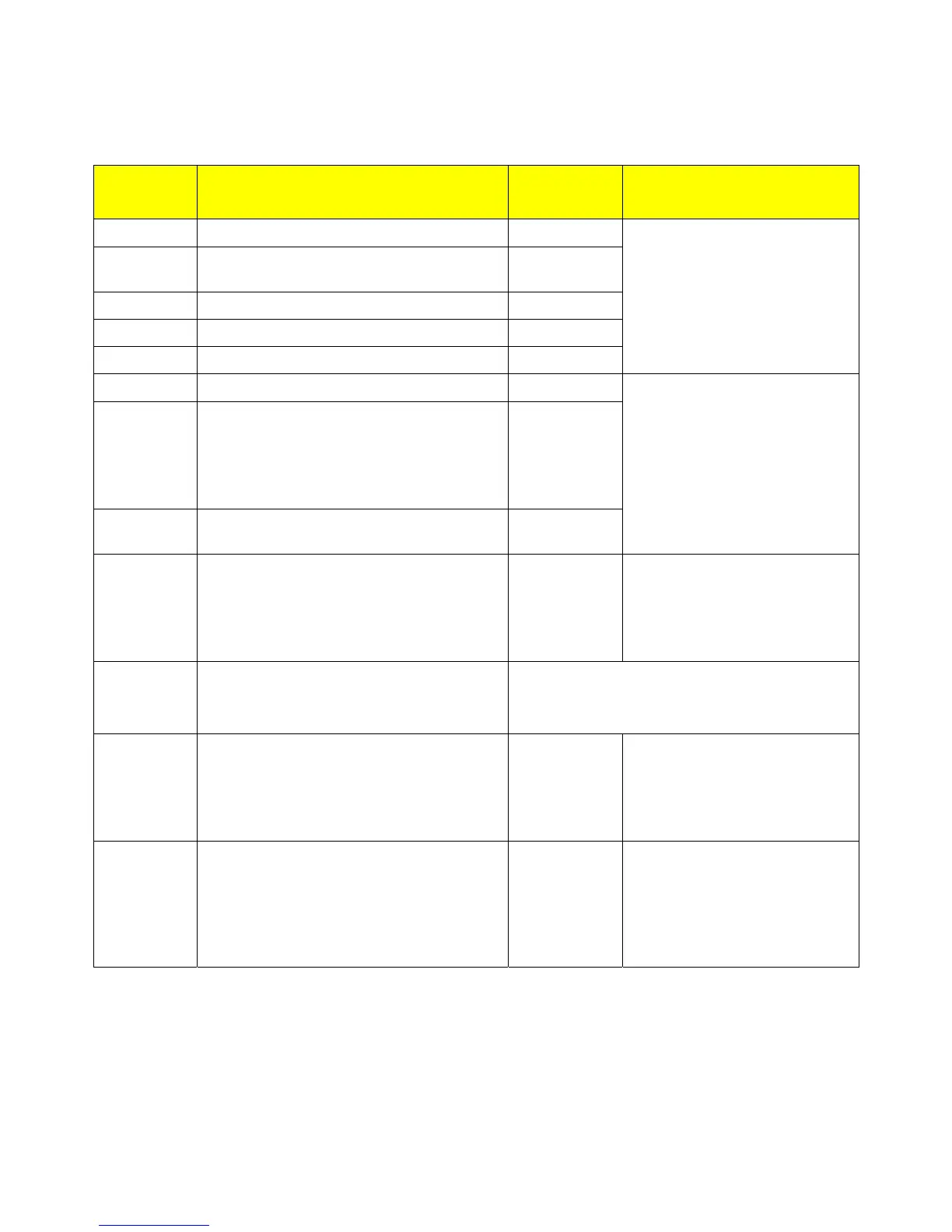

33

LUBRICATION

LUBRICATIONCHART

LUBRICATION

POINT#

LOCATIONDESCRIPTIONANDSERVICE

RECOMMENDATIONS

LUBRICATION

INTERVAL

RECOMMENDED

LUBRICANT

1 Idlerwheelbearing.Onegreasenipple. WEEKLY

Premiumquality,multi‐purpose

Lithium‐base,EP(extremepressure)

grease.

ShellAlvaniaEP‐0

2

Indexvisemovablejawways.Twogrease

nipples.

WEEKLY

3 Gearboxshaftbearings.Twogreasenipples. WEEKLY

4 Bandtensionslide.Onegreasenipple. WEEKLY

5 Sawheadtube.Onegreasenipple. MONTHLY

6 Sensingarm.Cleanandapplyoil. MONTHLY

Highquality,rustandoxidation‐

inhibited,mediumhydraulicand

generalpurposeindustrialoil.

ISO‐VGgrade68

ShellTellus68

7

Miscellaneous:viseslide,hinges,pivothinges,

componentparts,unpaintedsurfaces,etc.

Toensurefunctionandmaintainappearance

whilereducingwear,corrosion,rust,etc.Apply

whenandwhereneededinamountsrequired.

ASREQUIRED

8

Sawguideadjustmentscrews.Cleanandapply

oil.

INSERTCHANGE

9 Banddrivegearbox.

Capacitydependingonmodel.Seespecification

chart.Drain,changeandrefillafterfirstthree

months,everysixmonthsthereafter.Donot

overfill.Filluntilaboveredlineonsidegauge.

CHANGEAFTER

INITIALTHREE

ANDFURTHER

SIXMONTHS

Premiumgearboxoil.

ContactDoALLEuropaforproperoil

type.Thisvariesdependingon

model.

10 Electricandhydraulicmotors.

Banddrive,hydraulicpumpmotor,coolantpump

motor,chipaugermotor.

Lubricate(ifany)permanufacturer’srecommendation.

11 Coolantreservoir.

Capacitydependingonmodel.Seespecification

chart.Drain,cleanandrefillwhenevercoolant

becomesundesirableforfurtheruse.Cleanthe

meshscreenatthesametime.

CHECKDAILY/

REFILLAS

REQUIRED

Premiumquality,sawbandcoolant

andlubricant.

DoALLcuttingfluidsoroils.(Kool‐

ALL/KleenKool)

12 Hydraulicreservoir.

Capacitydependingonmodel.Seespecification

chart.Checkfluidleveldailyandkeepthe

reservoirfull.Drain,changethefilterelement

andrefillafteronemonthandeverysixmonths

thereafter.

CHECKDAILY/

CHANGEAFTER

INITIALONE

ANDFURTHER

SIXMONTHS

Highqualityhydraulicoil.

ISO‐VGgrade32

ShellTellus32

Lubricationintervalsarebasedonan8‐hour,40‐hourweek.

Lubricatemoreoftenwithheavieruse.

Loading...

Loading...