8. Fuel system

144

Droop parallel Operation mode (Manual

paralleling)

• Definition: Engine speed on the decrease against

Engine load on the increase.

DROOP(%) = {(No Load Speed - Full Load Rated

Speed) x 100} / Full Load Rated Speed

• Description: Droop is typically used for the l

oad

shar

ing and paralleling of engine driven generators.

Without the Droop mode in paralleling system, gener-

ators can be overloaded or motorized.

• Application: For DROOP Operation,

1. Close Droop selector switch between terminals K and

L.

2. When in Droop operation, the engine speed will

decrease as engine load increase. The percentage of

droop governing can be varied with (7) Droop poten-

tiometer. The higher level of droop is achieved

as

t

urning (7) Droop clockwise.

• Droop level requirements above 10% are unusual and

the minimum droop level to keep the stability of spe

ed

dr

oop governor is 2.5% or above.

• After the droop level has been adjusted, the rat

ed

engi

ne speed setting may need to be reset.

Check

t

he engine speed and adjust the speed setting accord-

ingly.

Accessory Input (Automatic Paralleling)

• The Auxiliary terminal N accepts input signals from

load sharing units, auto synchronizers, and other

governor system accessories.

• It is recommended that this connection from accesso-

ries be shielded as it is a sensitive input terminal.

• When an accessory is connected to Terminal N, the

speed will decrease and the speed adjustment must

be reset.

• When operating in the upper end of the control

system frequency range, a jumper wire or frequency

trim control may be required between Terminals G

and J. This increases the frequency range of the

speed control to over 7,000Hz.

Controller LAMP Display (diagnosis)

• Power : When the battery power is connected and

i

nner control power (DC 12V) is achieved, the lap is

on and main controller is ready to function.

• Pick Up : When the voltage between terminals C an

d

D i

s VAC 3.0 or above, the lamp is on.

• Crank : When the engine reaches the preset rate

d

spee

d (idle speed), the lamp is on and relevant rela

y

i

s achieved.

• Run : When the engine reaches the preset rat

ed

spee

d (operating speed), the lamp is on and relevant

relay is achieved.

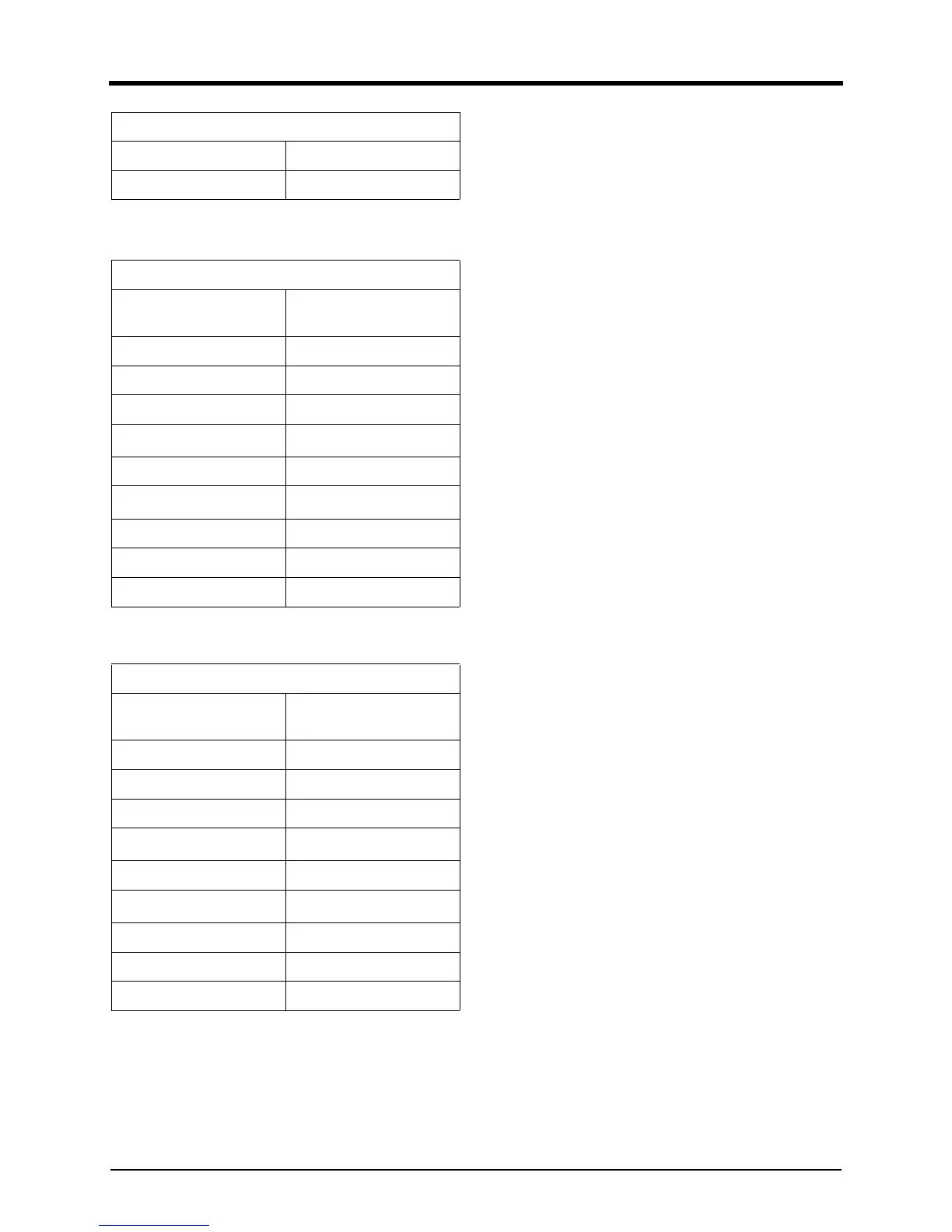

Speed Adjustment 4,800Hz (1800rpm)

Idle Adjustment 2,133Hz (800rpm)

a. CW: Clockwise

b. CCW: Countclockwise

300611-00685

Overspeed

1,725rpm (No. of teeth =

152)

Run lamp Maximum CW

Gain Mid-range (12 O’clock)

Stability Mid-range (12 O’clock)

Starting Fuel

Full CW

a

(Maximum Fuel)

a. CW: Clockwise

Speed Ramping 9 O’clock

Droop

Full CCW

b

(Minimum)

b. CCW: Countclockwise

Adjustment (No. of teeth = 160)

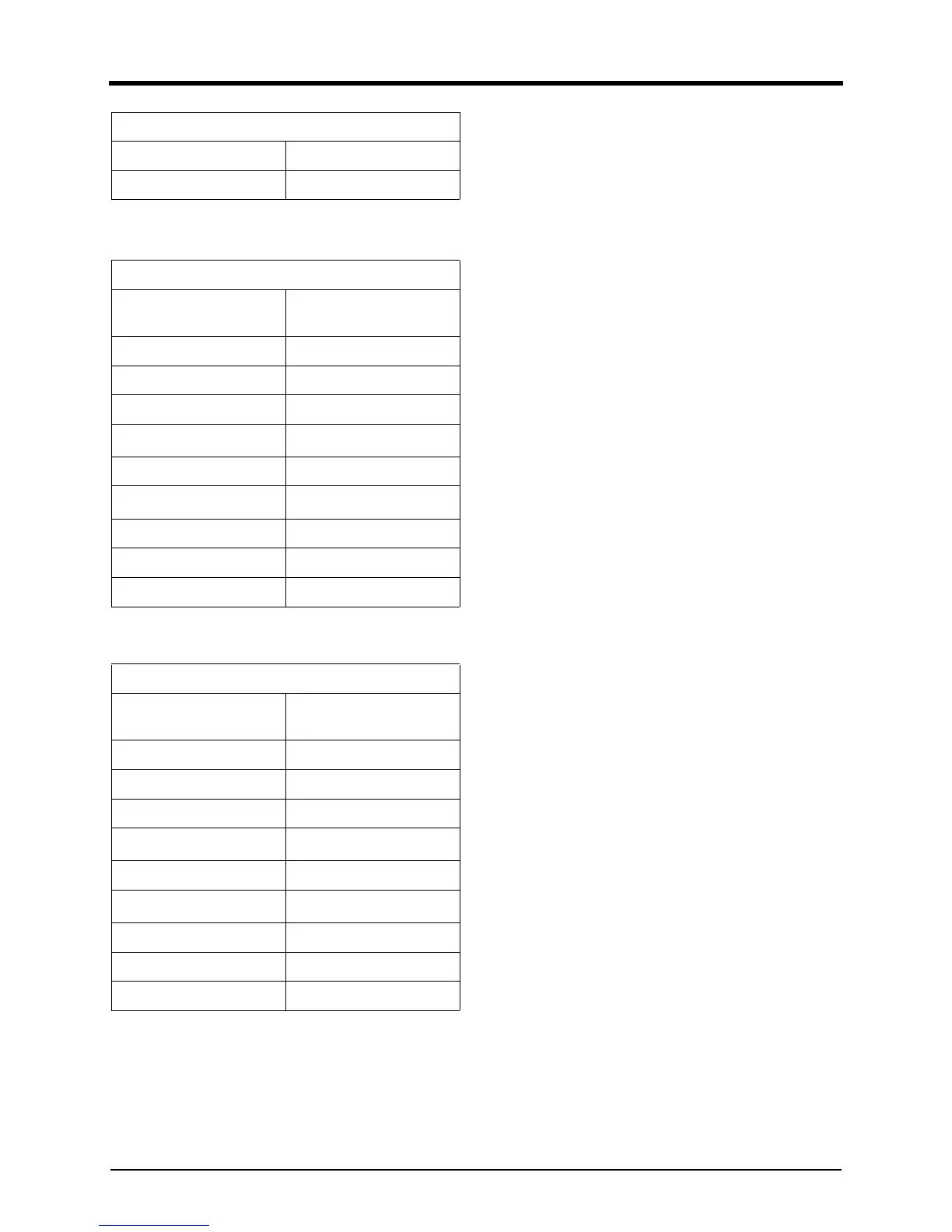

Speed Adjustment 3,800Hz (1500rpm)

Idle Adjustment 2,026Hz (800rpm)

300611-00686

Overspeed

2,070rpm (No. of teeth =

152)

Run lamp Maximum CW

Gain Mid-range (12 O’clock)

Stability Mid-range (12 O’clock)

Starting Fuel

Full CW

a

(Maximum Fuel)

a. CW: Clockwise

Speed Ramping 9 O’clock

Droop

Full CCW

b

(Minimum)

b. CCW: Countclockwise

Adjustment (No. of teeth = 160)

Speed Adjustment 4,053Hz (1800rpm)

Idle Adjustment 2,026Hz (800rpm)

300611-00684

Loading...

Loading...