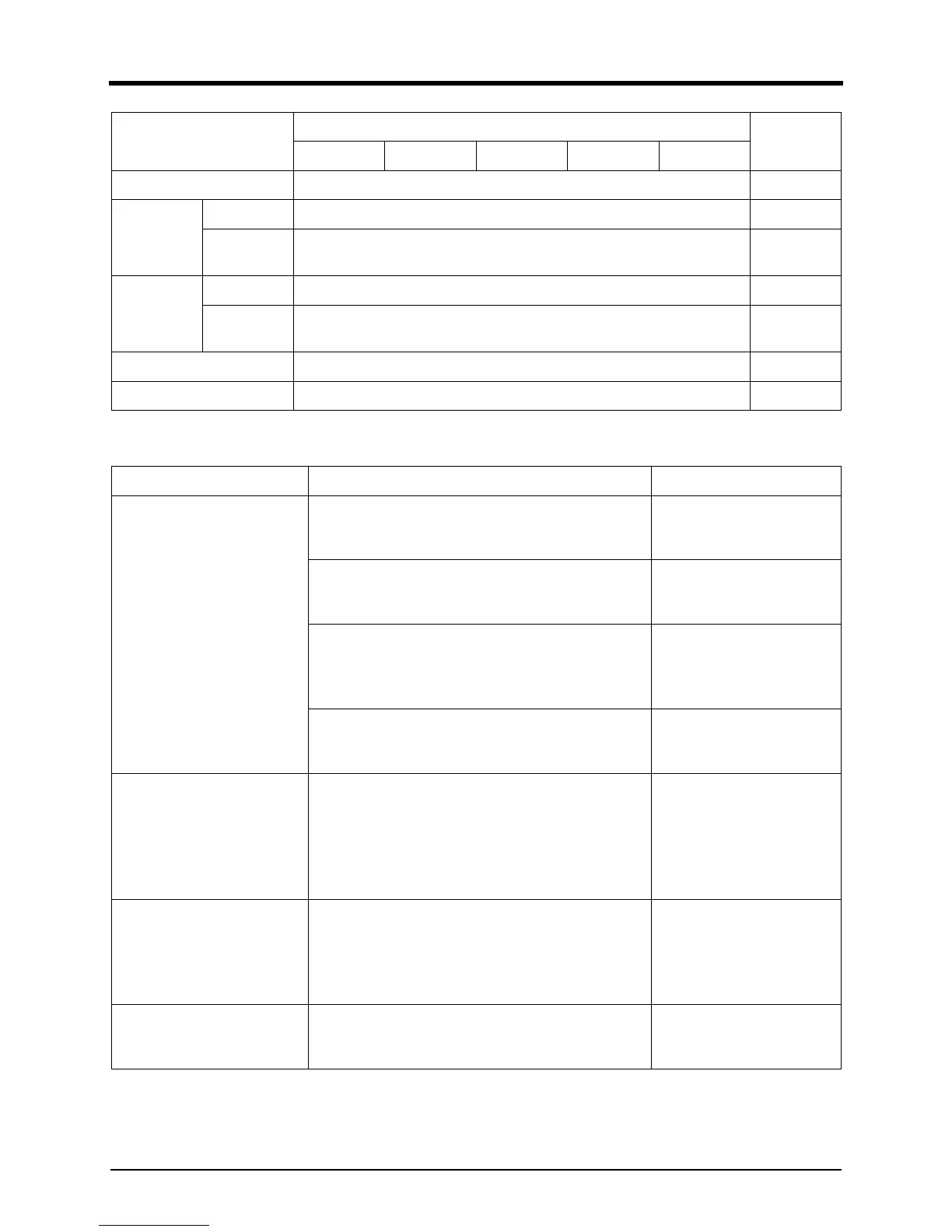

8. Fuel system

133

Failure Diagnosis

Governor Electric type

Fuel feed

pump

Type Mechanical type injection pump

Capacity

(L/hr)

630

Injection noz-

zle

Type Multi hole type

Opening pres-

sure (MPa)

28

Fuel filter Full flow, Cartridge type with water drain valve

Fuel Used Diesel fuel oil

Item

DP222L

Remarks

DP222LAS DP222LBS DP222LBF DP222LCS DP222LCF

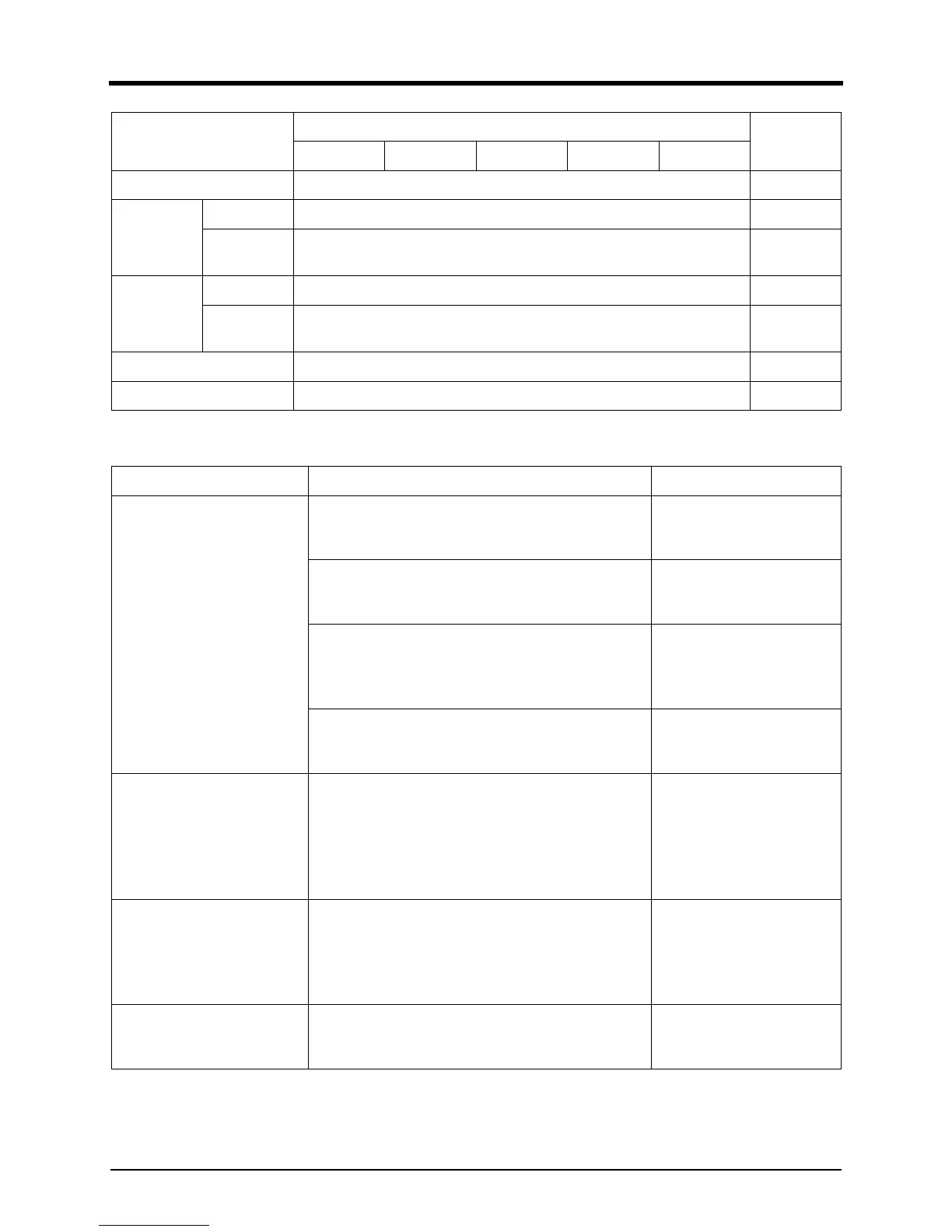

Symptom Causes Troubleshooting

1.

Engi

ne does not start

A. Fuel is not supplied from

the fuel delivery pump

B.

Fuel

is not injected from

the fuel injection pump

C.

I

mproper fuel injection tim-

ing

D.

Fuel

injection nozzle not

working

• Clogged fuel pipe, or air entered the fuel pipe line

• Defective delivery pump valve

• Seized delivery pump piston or push rod

•Correct

• Replace

• Disassemble / correct

• Clogged fuel filter cartridge

• Air entered to the fuel filter or injection pump

• Seizure or defect in the plunger or delivery valve

• Clean / replace

•Bleed

• Disassemble / correct

• Defective installation of fuel injection pump bracket

• Defective adjustment of the fuel injection pum

p

t

appet

• Excessively worn cam of camshaft

• Inspect / correct

• Inspect / correct

• Replace

• Seizure of needle valve of nozzle

• Fuel leakage between nozzle and needle valve

• Improper fuel injection pressure

• Service or replace

• Service or replace

•Adjust

2.

Engi

ne starts but stop

s

immediately

• Clogged fuel filter or clogged pipe between fuel

delivery pump and injection pump

• Air entered into fuel

• Insufficient supply of oil by fuel delivery pump

• Clogged air breather in fuel tank, causing insuffi-

cient fuel supply.

• Clean or replace

• Air bleeding

• Disassemble / correct

• Replace breather

3.

I

nsufficient engine power

• Excessively work plunger

• Improper injection timing

• Defective delivery valve

• Excessive fuel leakage in injection nozzle

• Nozzle not working properly

• Replace

•Adjust

• Replace

• Service or replace

• Disassemble / correct

4.

Engi

ne knocking occurs

• Early injection timing

• High nozzle injection pressure

• Nozzle not working properly

•Adjust

•Adjust

• Disassemble / correct

Loading...

Loading...