10. Cylinder block/head

175

Valve Seat

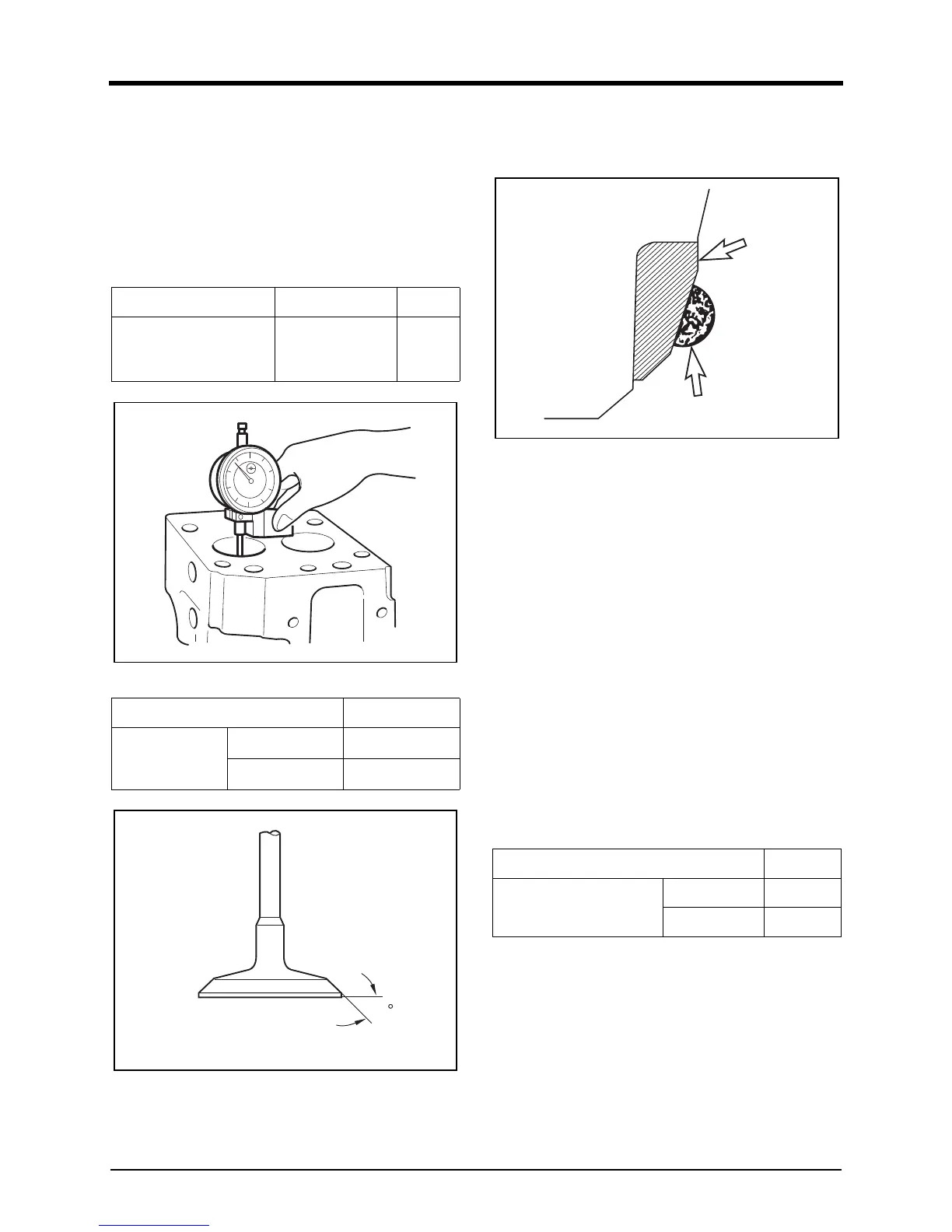

1. Visual inspection: Inspect the damage and wear of

valve seat and if necessary replace.

2. Valve seat thickness and angle: Assemble the valv

es

a

t the cylinder head and using the measuring instru-

ment from the lower face, measure the projecti

on

amount of valve. If the measured value is more than

the use limit, replace the valve seat.

DV2213120A

DV2213121A

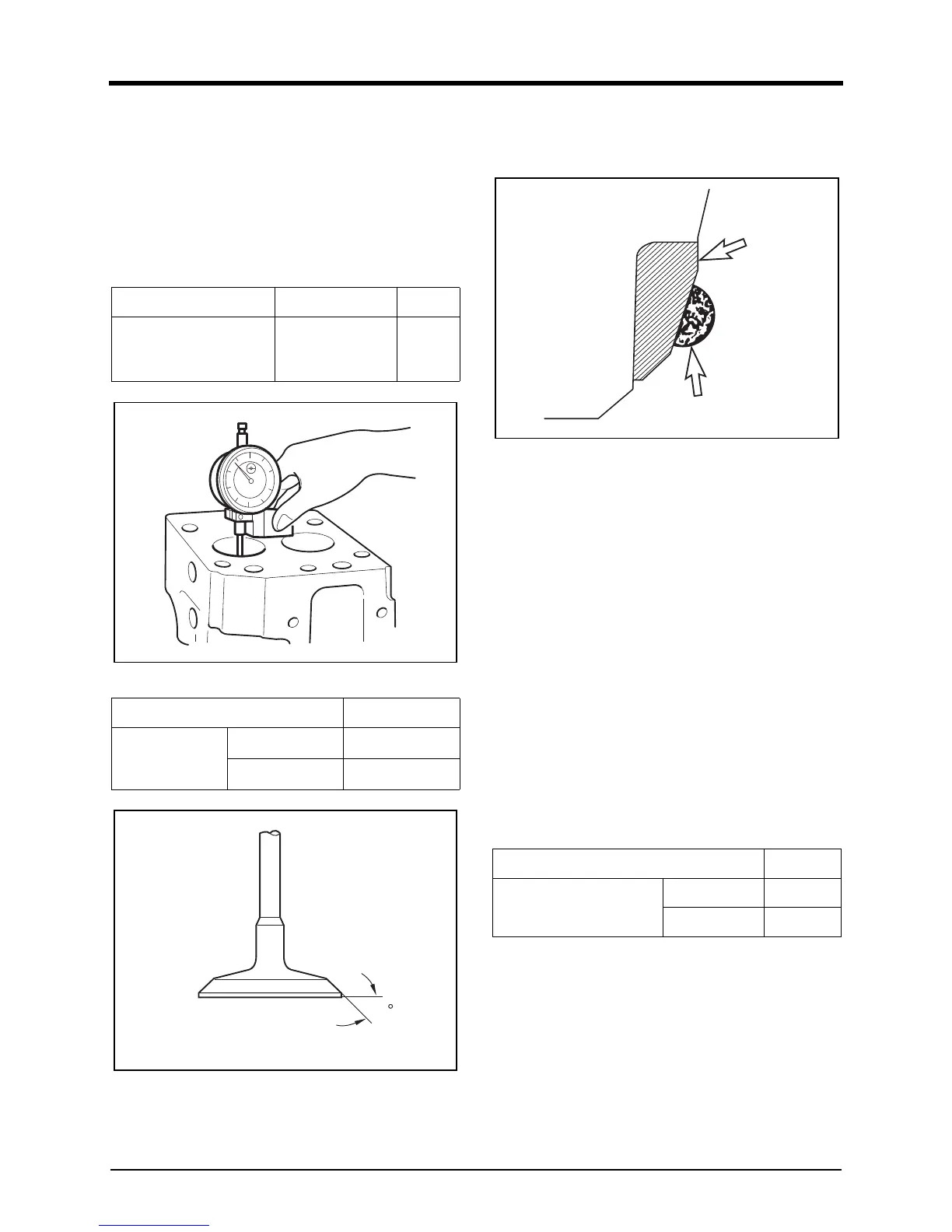

3. The disassembly of valve seat cam be pulled out by

means of a special tool with the arc welding done at

two points of valve seat rotating tool or valve seat.

DV2213122A_E

4. Regarding the valve seat assembling, shrink the valve

seat by putting it in the dry ices for about 1 hour or

so, and then press it into the cylinder head by me

ans

of

a special tool.

5. After coating the grinding powder paste on valve h

ead

contacting face of valve seat, and after executing a

suf

ficient lapping operation with the rotating an

d

gr

inding motion of valve, wipe off the grinding agent

thoroughly.

Valve Spring

1. Visual inspection: Check if the exterior of the valve

spring is damaged with the naked eye. Replace it with

a new one if required.

2. Fee length of valve spring: Measure the free lengt

h

of

the valve spring with the vernier clipers. If t

he

r

eading is larger than the specified valve, replace t

he

val

ve spring.

Item Standard Limit

Valve seat thickness

(at cylinder head sur-

face)

0.65 ~ 0.95mm 2.5mm

Item Limit

Valve seat angle

In. Valve

30°

Ex. Valve

45°

10

20

30

40

50

60

70

80

90

0

45

Item Limit

Fee length of valve spring

Inside 65.5mm

Outside 64mm

Cylinder head

Valve sheet

Weld bead

Loading...

Loading...