8. Fuel system

146

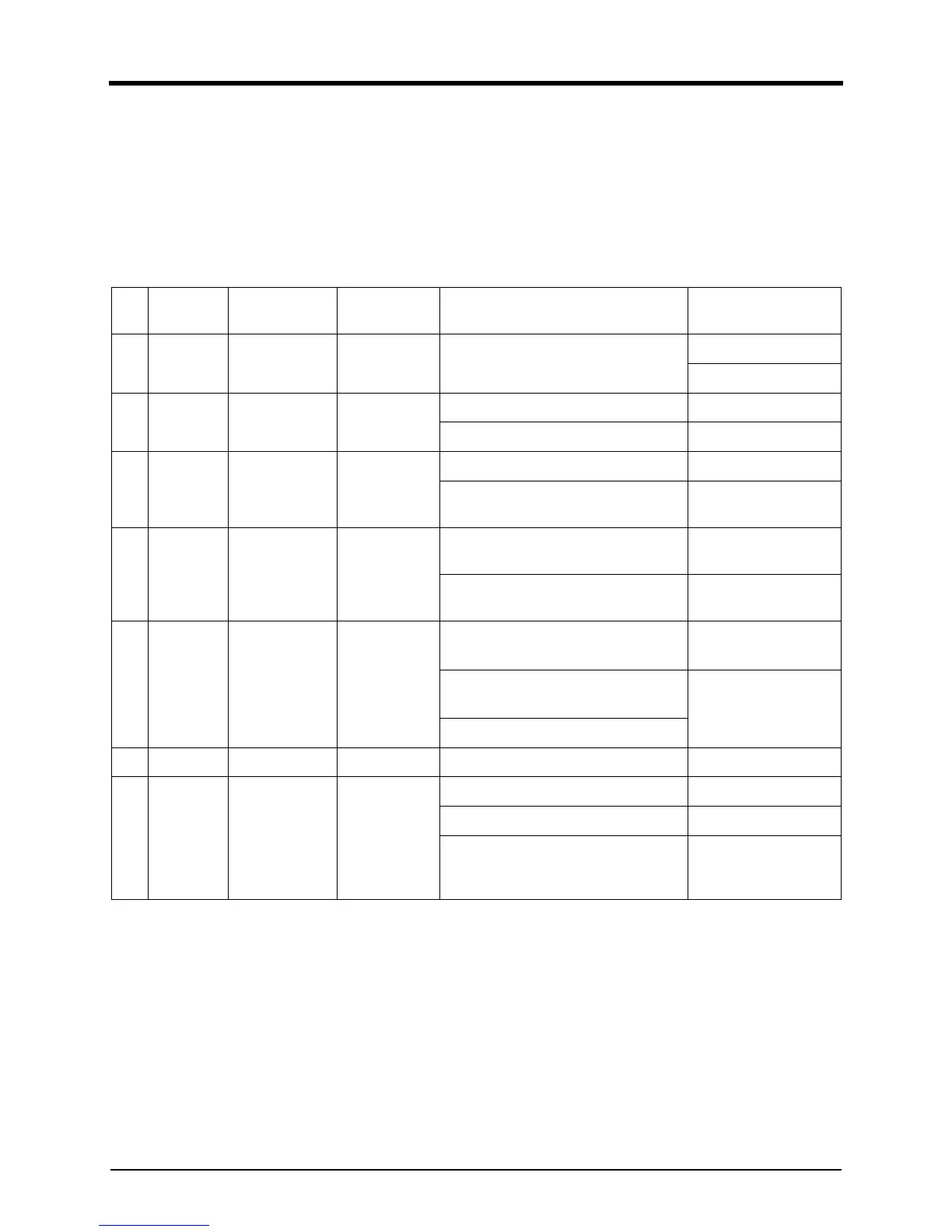

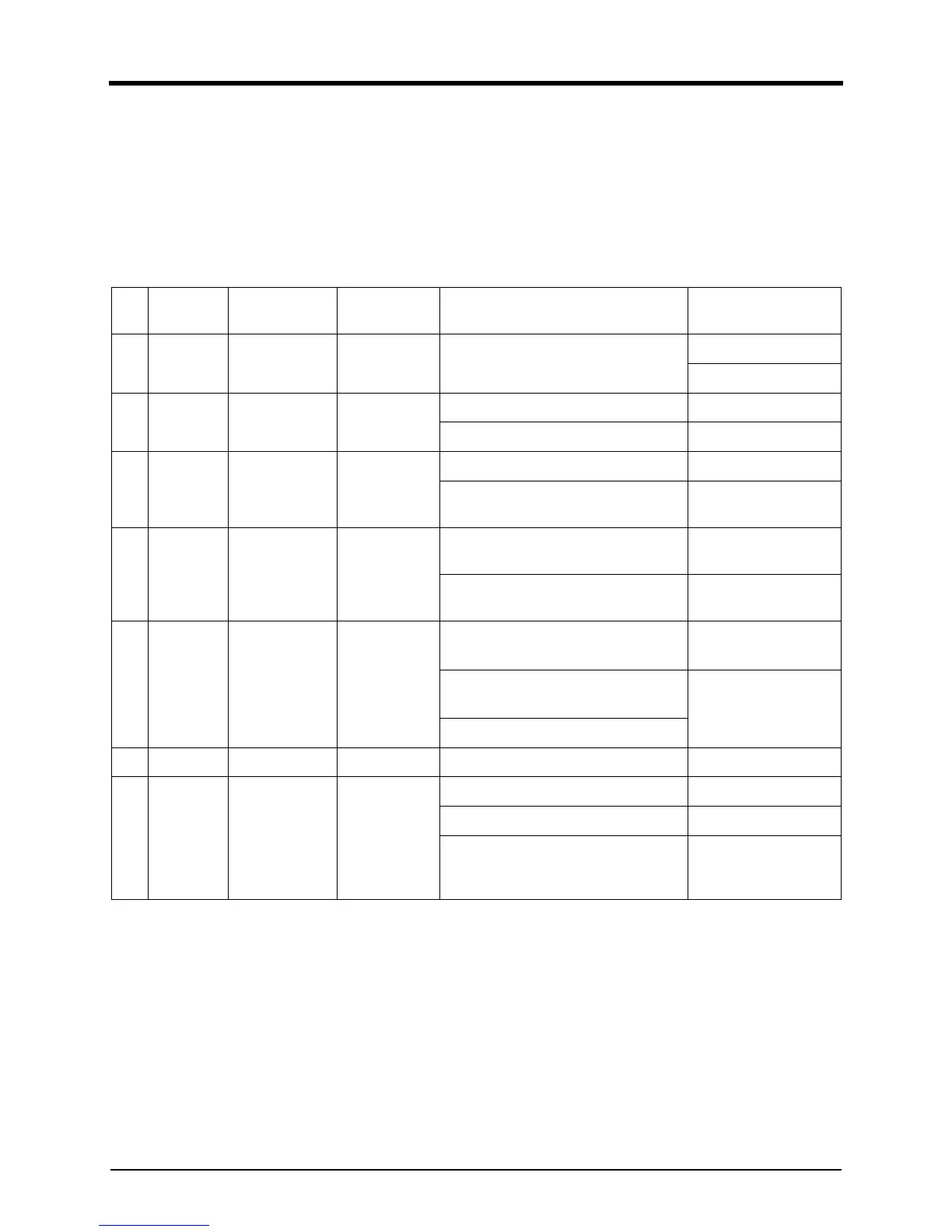

System inoperative

If the engine governing system does not function, the

fault may be determined by performing the voltage tests

described in steps 1, 2 and 3. (+) and (-) refer to meter

polarity. If normal values should be indicated as a result

of following the troubleshooting steps, the fault may be

with the actuator or the wiring to the actuator. In that

case, check the actuator.

Ste

p

Terminal

When to Take

the Reading

Normal read-

ings

Probable Cause of Abnormal Read-

ing

Solution

1 F(+) & E(-)

When the

engine stopped

DC 24V

1.

Check

battery line

2.

Repl

ace battery

2 F(+) & E(-)

When starting

the engine

DC 15V or

above

1. Low battery voltage 1. Check battery line

2.

W

iring error 2.

Repl

ace battery

3C & D

When the

engine stopped

300~1200Ω

(tester ohmme-

ter)

1.

D

efective speed sensor 1.

Check

sensor line

2. Improper or defective wiring to th

e

s

peed sensor

2.

Repl

ace speed sen-

sor

4C & D

When starting

the engine

1.5V or above

(tester AC volt-

meter)

1.

Th

e gap between speed sensor an

d

g

ear teeth too great.

1.

Check

sensor line

2.

D

efective speed sensor

2.

Repl

ace speed sen-

sor

5A & B

When the

engine stopped

3.8~4.5 Ω (tes-

ter ohmmeter)

1. If the voltage reading is belo

w

3.

8 Ω => Short

1.

Check

short/op

en

act

uator

2. If the voltage reading is a

bove

4.

8 Ω => Open wire

2.

Repl

ace actuator

3.

D

efective actuator

6 P(+) & G(-) KEY S/W ON DC 9.5~10.5V Defective speed controller Replace controller

7 F(+) & A(-)

When starting

the engine

DC 9~15V in

normal condi-

tions DC 1~3V

in abnormal

conditions

1.

Speed adj

ustment set too low. 1.

Check

speed setting

2.

Shor

t/open in actuator wiring 2.

Check

actuator line

3.

A

ctuator

3.

Repl

ace actuator

when found to

be

def

ective

Loading...

Loading...