4. Regular inspection

54

Fuel system

General Information

The fuel injection pump and nozzle are composed of very

sophisticated components with high precision. If fuel is

mixed with foreign substance, it may clock the nozzle or

the fuel injection pump components may be seized. So,

be sure to keep the fuel system clean all the time.

Fuel Standards

The quality of fuel is very important to satisfy the engine

performance, extension of engine life and the allowable

exhaust gas level. Doosan engine engine is designed to

use diesel fuel available in the local market. If you want

the optimum engine performance, select the proper fuel

referring to the fuel selection table below.

• Low Sulfur Diesel

Note) High sulphur content in diesel fuel Doosan diesel

engines can be operated with fuels whose sulphur

content is max. 0.05wt%. Fuels with a sulphur

content of > 0.05wt% are not permitted as they

result in increased corrosion and hence greatly

reduce the service life of engines. The oil change

intervals must be halves if the sulphur content is >

0.02wt%.

• Use clean, certified and qualified fuel only. Using

i

rregular or unspecified fuel may cause critical

damage and faults to the engine.

• Replenish fuel while the engine is stopped.

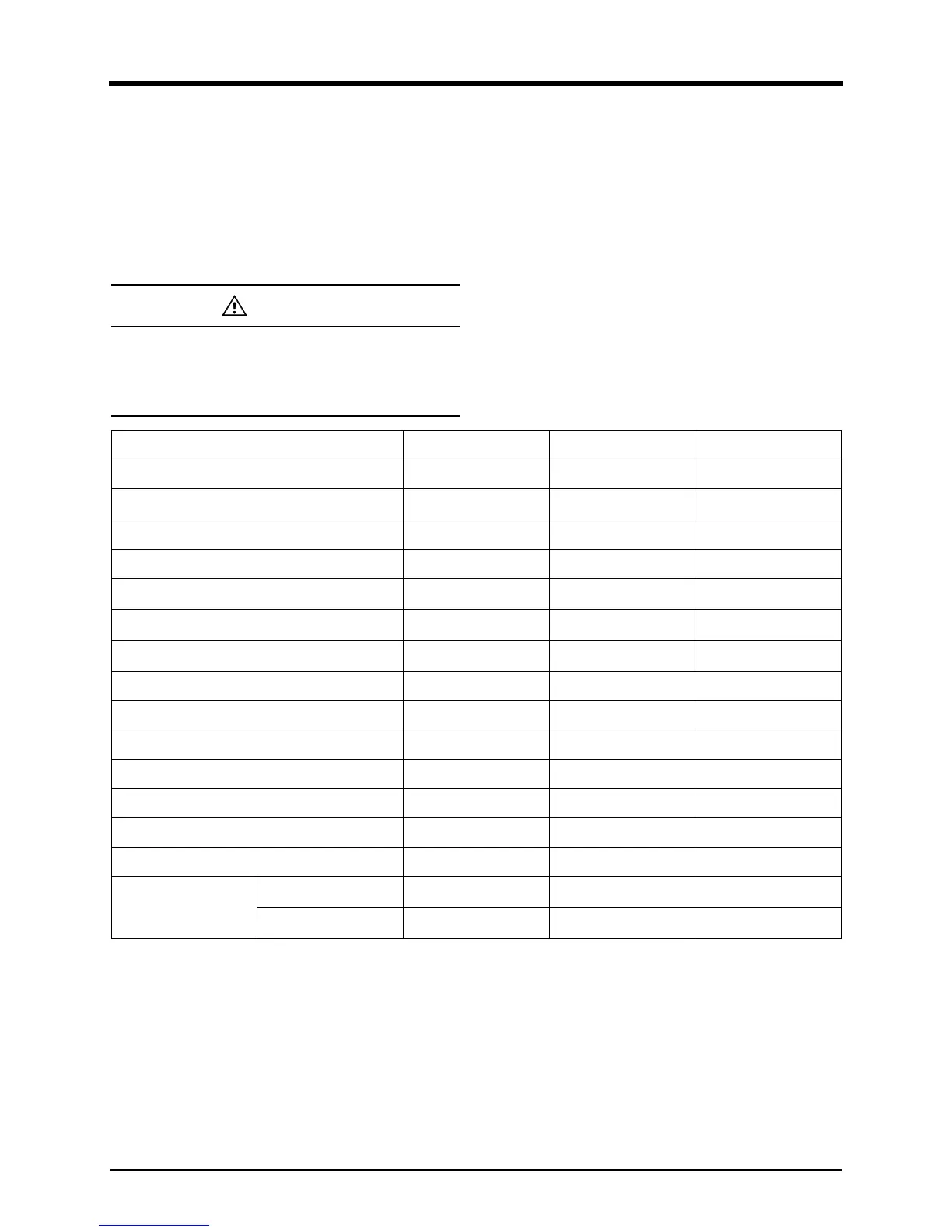

Fuel Ingredients Unit Standard Product

Specific Gravity (kg/lit) - 0.83

Flash Point

(°C)

>

40

47.8

Viscosity (40°C) (cSt) 1.955 2.459

Sulfur content (wt%) < 0.05 0.038

Cloud point

(°C)

--3

Pour Point

(°C)

< -17.5 -27.2

Low temperature filter clogging point

(°C)

< -12 -18

Color (ASTM) < 2.5 0.7

Carbon Residue (10%) Distillation residue (wt) (%) < 0.15 0.08

Total acid value (mg KOH/g) < 0.40 0.03

Copper corrosion (100°C, 3 hrs) < 1 1 - a

Ash content (wt) (%) < 0.01 0.001

Moisture and Precipitate (vol. %) < 0.01 0.005

Cetane Index >

45

52

Distillation test tem-

perature

50% Distillation Point

(°C)

- 264.4

90% Distillation Point

(°C)

< 360 344.3

Loading...

Loading...