9. Intake/exhaust system

158

Function

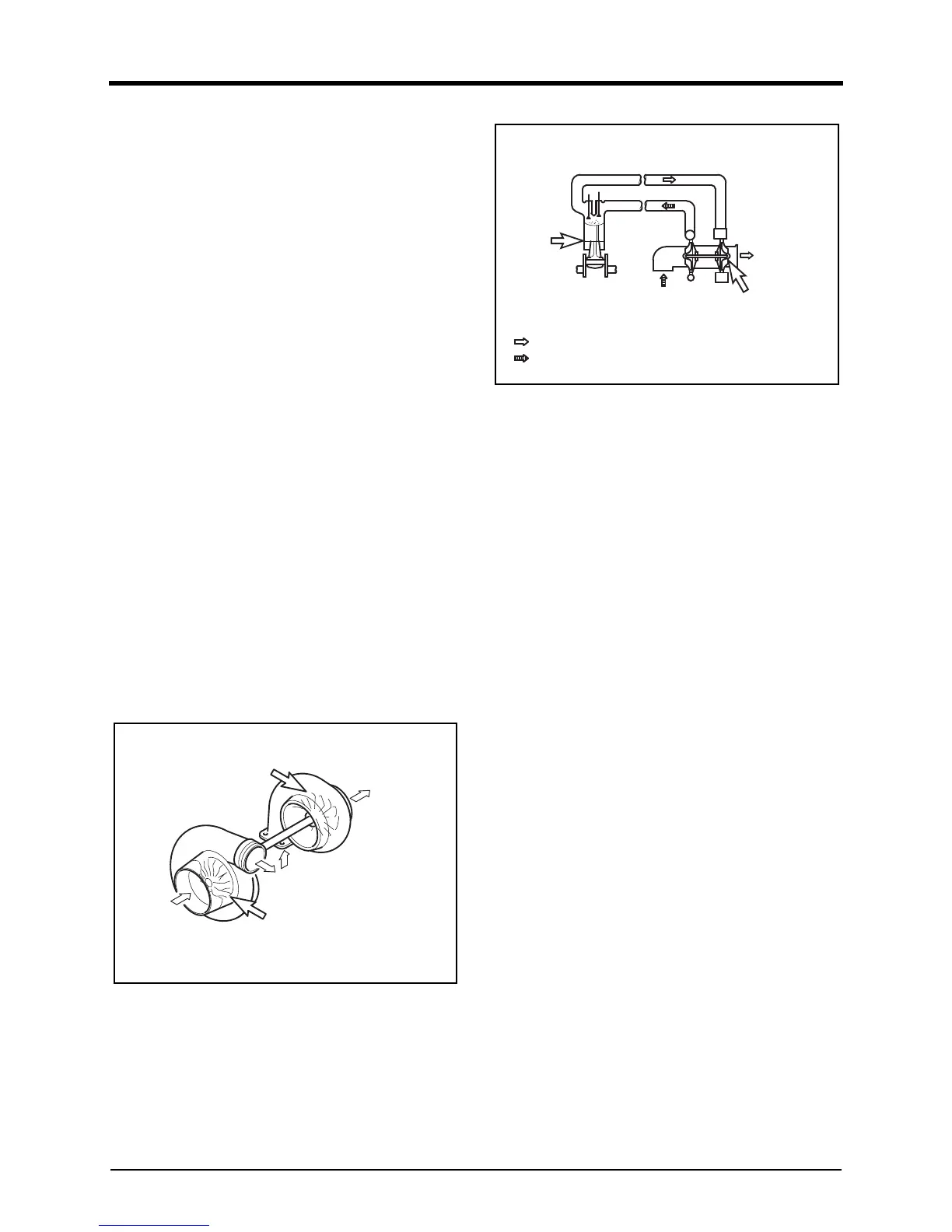

1. Turbine

The exhaust gas that is discharged from combustion

chamger passes through turbine housing conveying an

energy to turbine wings to give the rotating power,

This is called as the turbine and in order not to influ-

ence a bad effect at bearing part, there are the seal

ring and heat dissipator.

2. Compressor

It is connected to the same shaft with the turbine to

make a revolving assembly, and receive the revolvi

ng

f

orce of turbine, and sends air to the suction manifold

by suctioning and compressing it. This is called as th

e

c

ompressor.

3. Bearing

1) Thrust bearing force is applied to the turbine wheel

and an arrangement is made for the shaft not to shift.

2) journal bearing (floating bearing) is adopted and it

forms the double oil films at the in out surfaces in

comparison to the general stationary type so that t

he

b

earing may be able to rotate independently and

consequently the double layers of films act as th

e

d

amper to make the slipping speed on the beari

ng

s

urface less than the rotaing speed of shaft so that

the dynamic stability may be obtained.

4. Sealing at compressor shaft

Inorder for the compressed intake air and lubricatin

g

o

il not to leak, a seal plate and a seal ring are made

to the double structures.

DV2213109A_E

DV2213110A_E

Turbine Wheel

Exhaust gas

outlet

Suction air

inlet

Compact wheel

Exhaust gas

inlet

Compressed air supply

Loading...

Loading...