4. Regular inspection

68

Others/driving system

V-Belt

The tension of the V-belts should be checked daily .

1. Change the V-belts if necessary

1) If in the case of a multiple V-belt drive, wear or

differing tensions are found, always replace t

he

c

omplete set of V-belts.

2. Checking condition

1) Check V-belts for cracks, oil, overheating and wear.

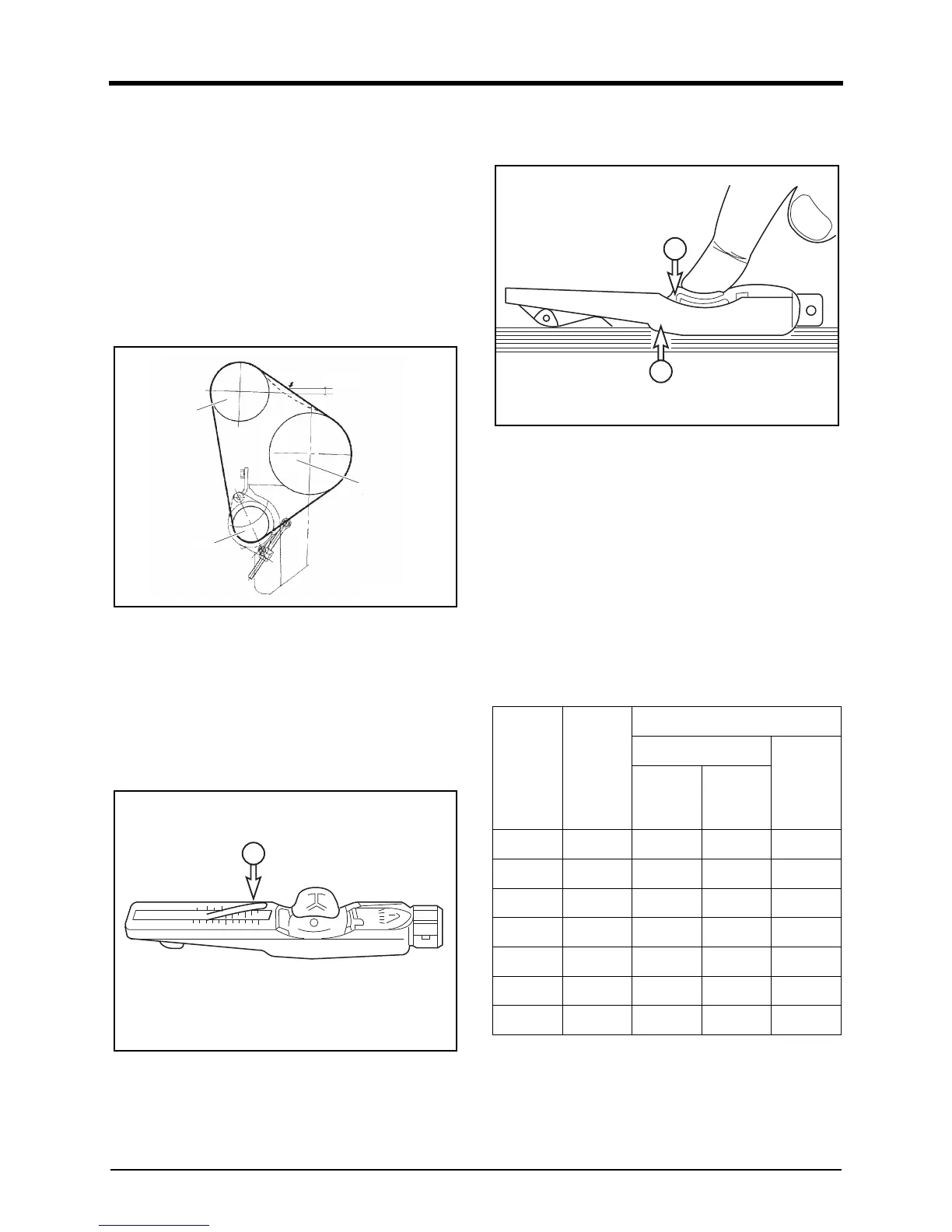

3. Testing by hand

DV2213047A_E

1) For the V-belt tension, when you press the center

between pulleys, if it is pressed by 10~15mm, it is

normal.

2) To check the tension of V-belt more accurately,

you

c

an use a V-belt tension gauge.

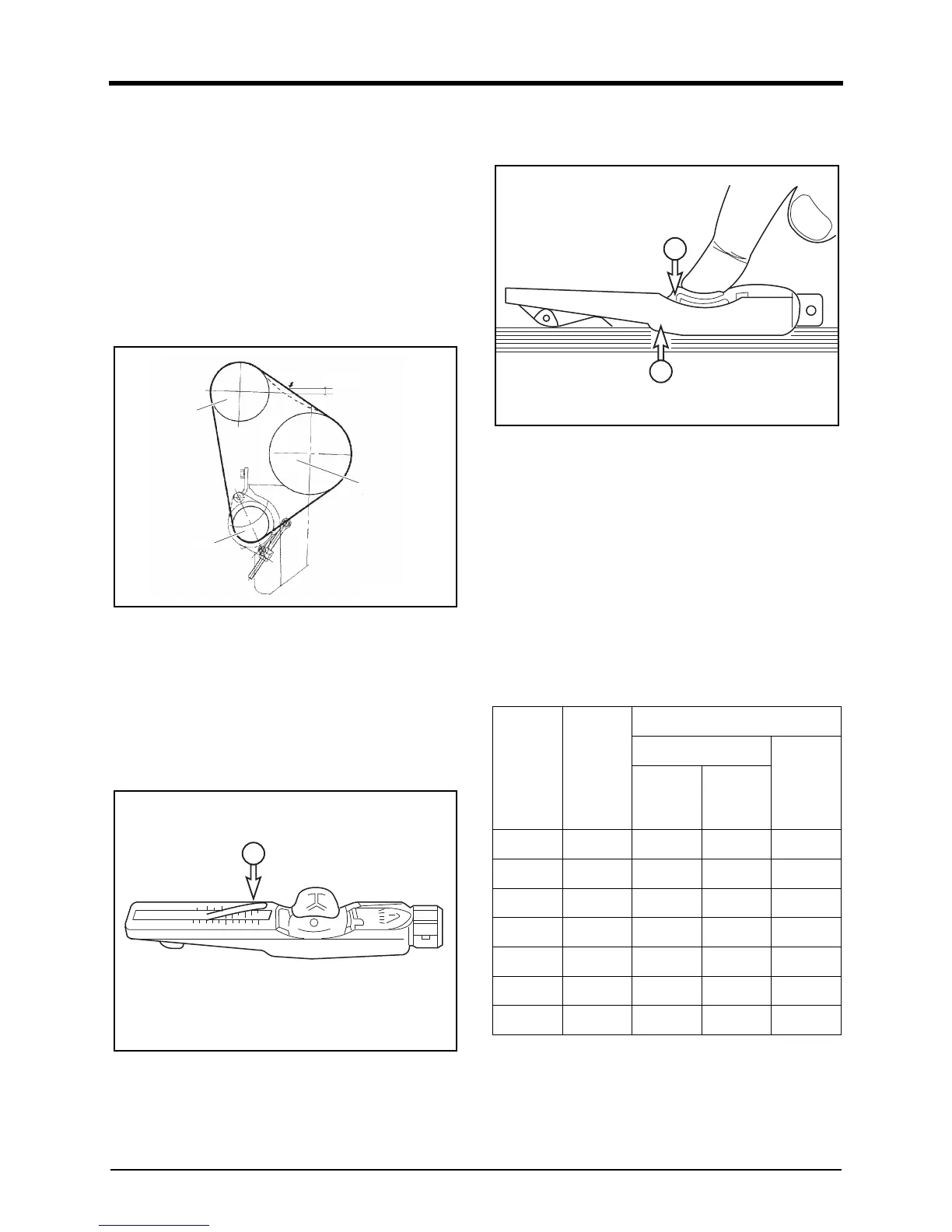

4. Tension measurement

1) Lower indicator arm (1) into the scale.

DV2213048A

2) Apply tester to belt at a point midway between two

p

ulleys so that edge of contact surface (2) is fl

ush

wi

th the V-belt.

DV2213049A

3) Slowly depress pad (3) until the spring can be heard

t

o disengage. This will cause the indicator (1) to mo

ve

upwar

ds.

Note) If pressure is maintained after the spring has disen-

gaged a false reading will be obtained.

4) Read the tension value at the point that the t

op

sur

face of indicator arm(1) intersects with the scale.

5) Before taking readings makes ensure that the indicator

arm remains in its position.

Note) If the value measured devotes from the setting

value specified, the V-belt tension must be

corrected according to the following table.

Loading...

Loading...