5. About the engine

76

Note) The standard torque values above are about 70%

of the bolt elastic limit values.

Note) The tensile force has been calculated by multiplying

the tensile strength with the screw cross-sectional

area.

Note) A special screw should be tightened with 85% of

the tightening torque of the standard value. For

example, a MoS2-coated screw should be tightened

with 60% of the tightening torque of the standard

value.

2. Tightening Torque of Key General Bolts

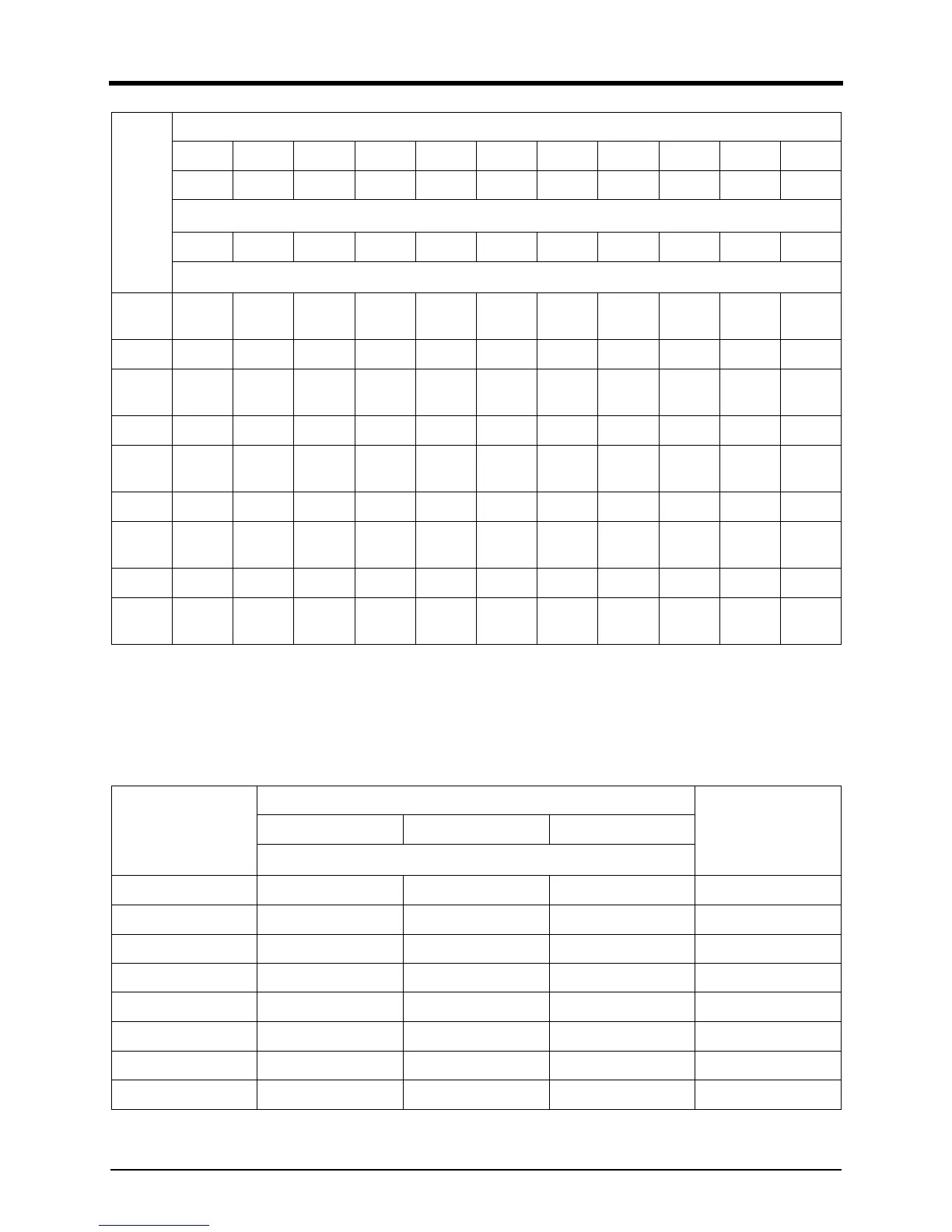

M16 x

1.5

6.2 6.5 9.7 8.6 12.5 11.3 17 19.5 20 28 33

M18 7.8 8.3 12.5 11 16 14.5 21 24.2 25 36 43

M18 x

1.5

9.1 9.5 14.5 12.5 18.5 16.7 24.5 27.5 28 41 49

M20 11.5121816221931.535365160

M20 x

1.5

12.8 13.5 20.5 18 25 22.5 35 39.5 41 58 68

M22 15.51624.52130264246496775

M22 x

1.5

1718.5282434294752567585

M24 20.521.5332740345558638292

M24 x

1.5

23 25 37 31 45 38 61 67 74 93 103

Nomi-

nal

Diame-

ter ×

Pitch

(mm)

Strength Classification

3.6 4.6 4.8 5.6 5.8 6.6 6.8 6.9 8.8 10.9 12.9

(4A) (4D) (4S) (5D) (5S) (6D) (6S) (6G) (8G) (10K) (12K)

Elastic Limit Value (kg/mm

2

)

20 24 32 30 40 36 46 54 64 90 106

Tightening Torque (kg·m)

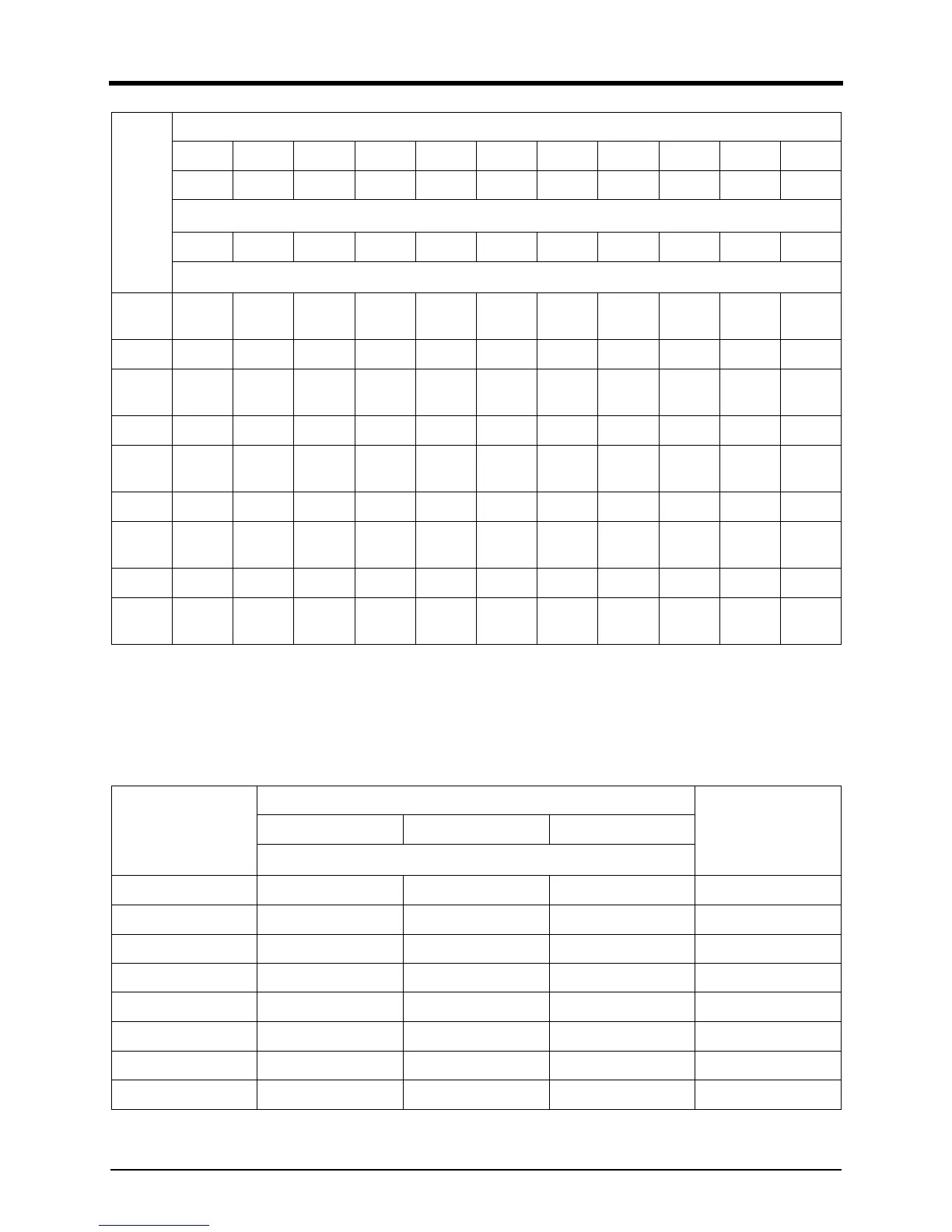

Nominal Diameter x

Pitch (mm)

Strength Classification

Remarks

8.8T 10.9T 12.9T

Tightening Torque (kgf·m) ± 10%

M6 x 1 1 1.25 1.5

M8 x 1.25 2.2 3.1 3.8

M8 x 1 2.4 3.35 4.1

M10 x 1.5 4.4 6.2 7.4

M10 x 1.0 5 7 8.4

M12 x 1.75 7.5 10.5 12.5

M12 x 1.5 8 11.2 13.4

M14 x 1.5 13 18.5 22

Loading...

Loading...