5. General Engine Information

65

Engine Assembly

Order of Engine Assembly

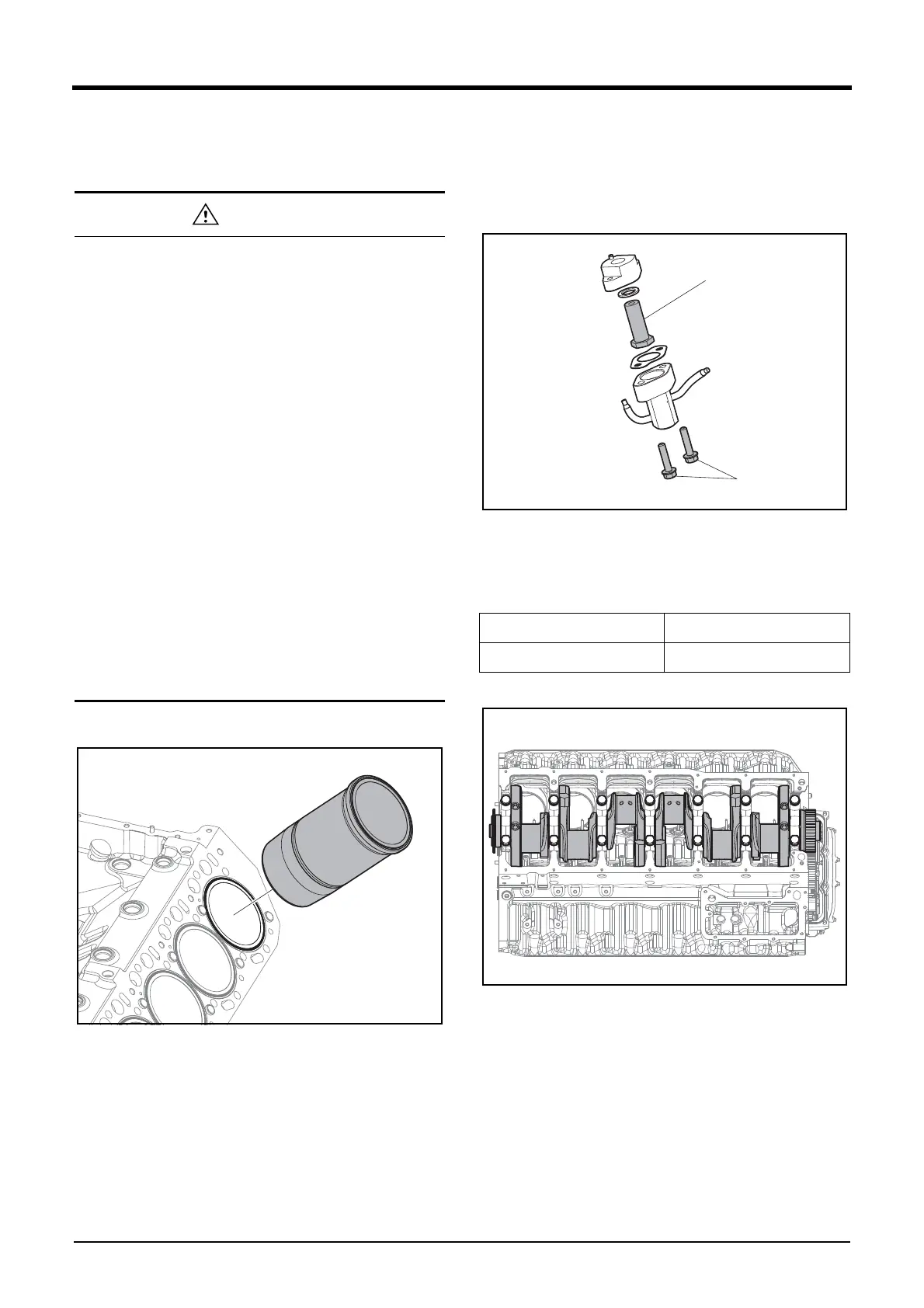

1. Cylinder liner

EDX22190108

1) Replace the O-rings with new ones. Insert the upper

O-ring into the cylinder liner and the lower O-ring into the

cylinder block.

2) Apply oil to the O-ring joint.

3) After gently inserting the cylinder liner into the liner hole

in the cylinder block, insert the O-ring while taking care

not to damage it.

4) After completely assembling the cylinder liner, perform a

hydrostatic test (4 kg/cm

2

) to check for leaks.

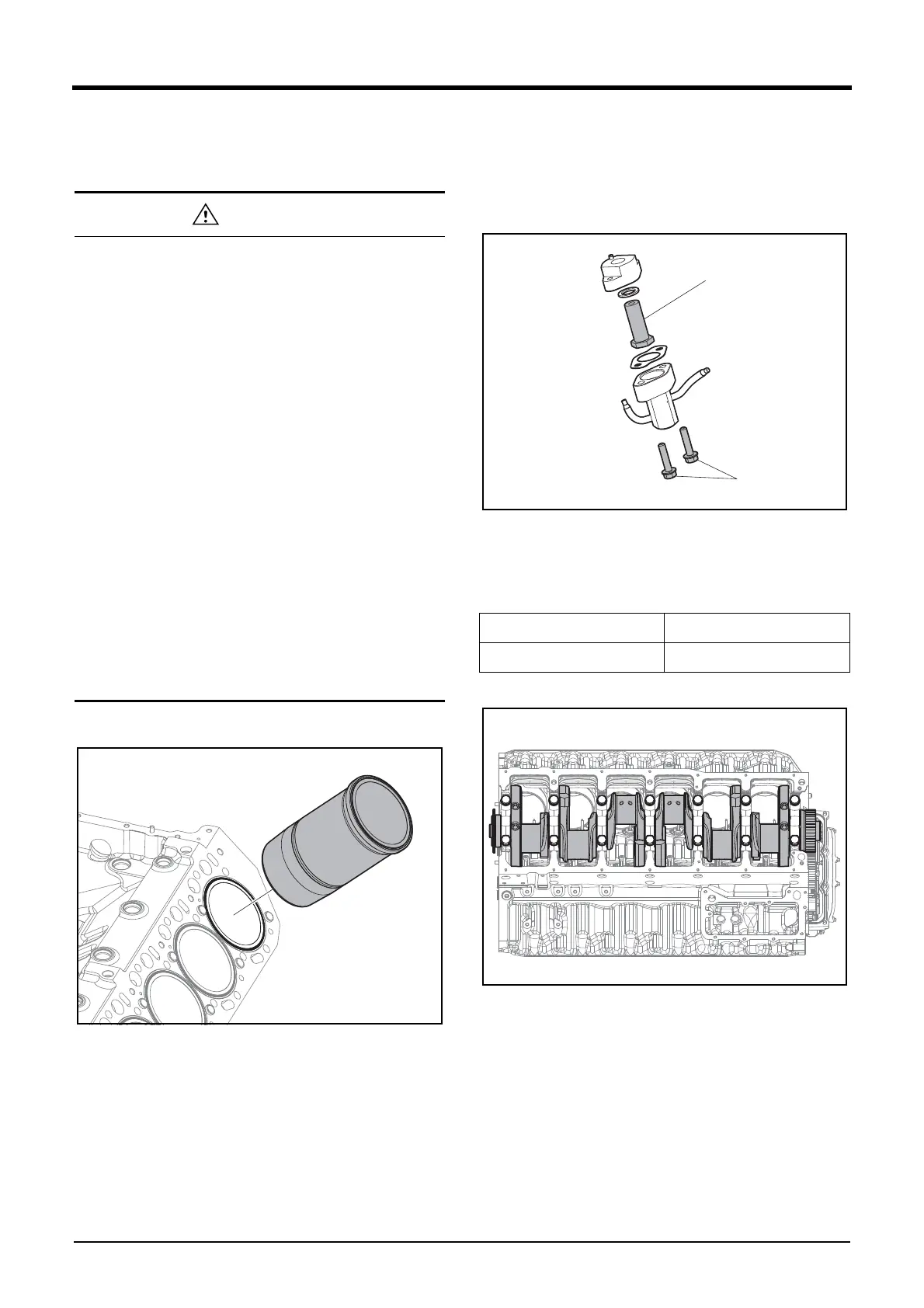

2. Oil injection nozzle

EDX22190109

1) Tighten the oil injection nozzle flange with hollow screw

(A).

2) Assemble the oil injection nozzle with mounting bolts (B).

3. Crankshaft

EDX22190096

1) Place the wear ring in a heater and heat it to 150 ~ 200 °C

(302 ~ 392 °F); then, use a jig to fit it onto the crankshaft.

• Clean all parts thoroughly and blow compressed air

into the various oil and coolant passages to clean

them out completely.

• Arrange the various special and general tools for

assembly in order.

• Prepare clean engine oil to apply to each moving

part.

• Prepare other materials such as sealant.

• Use ThreeBond as an adhesive in the engine oil

circuit and silicone in the cooling circuit.

• Used gaskets, seal rings and other consumable parts

should be discarded and replaced with new ones.

• Each bolt should be tightened to its specified torque

in order and should not be overtightened.

• After assembling engine components, check to make

sure that the engine moves smoothly.

• After assembly is complete, check each bolt for

looseness.

• After completely assembling the engine, check for

any missing or faulty parts.

• Keep your hands clean while working.

Hollow screw torque 7 kgf·m (50.6311 lbf·ft)

Mounting bolt torque 1.2 kgf·m (8.6796 lbf·ft)

Loading...

Loading...