G424F(FE) Service Manual Chapter 3. Engine Mechanical System 43

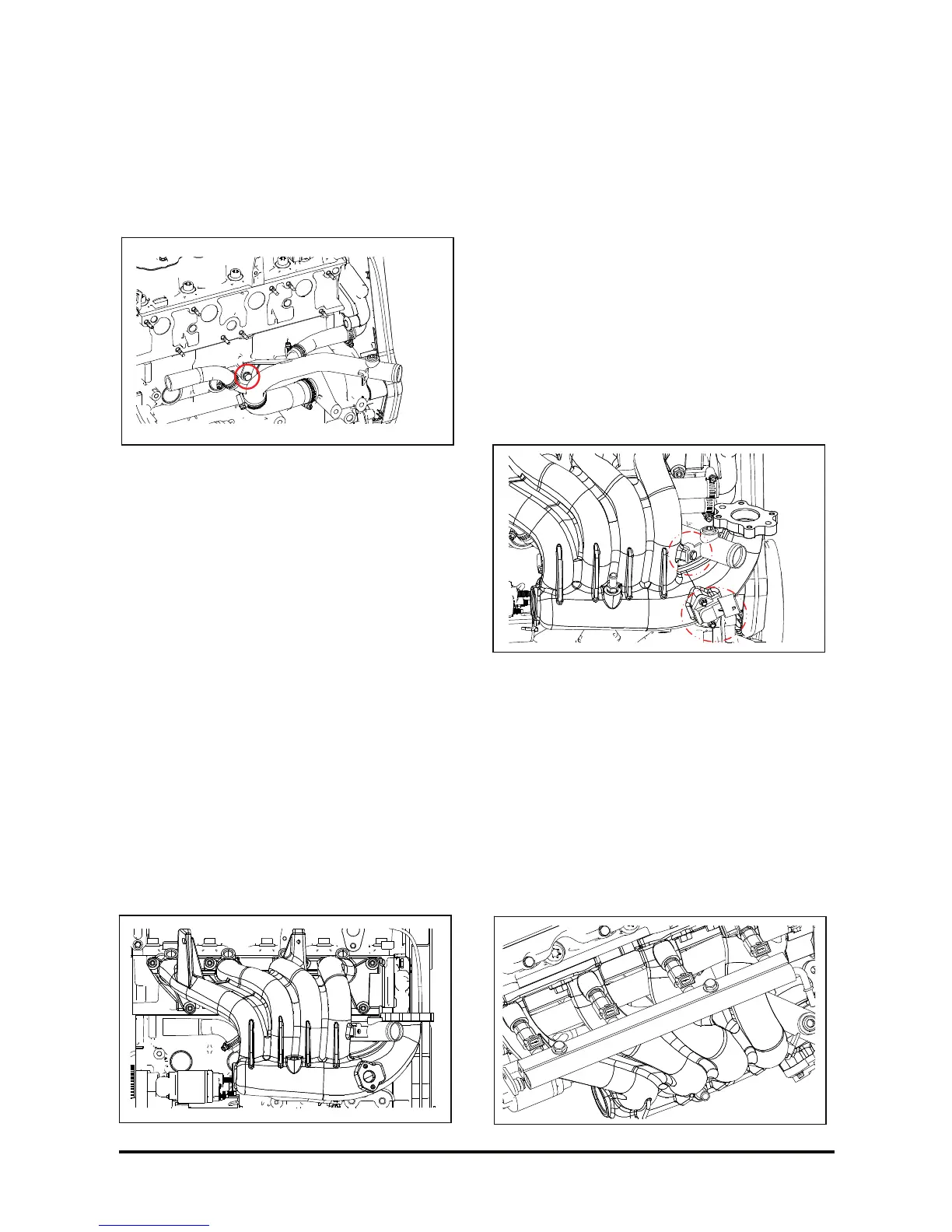

Installation

Install or connect

1. Coolant pipe attaching bolt with cylinder block in

its place.

2. With 13mm torque spanner, proper torque; tighten.

Tighten

• Bolts: 18 – 22 N·m (13 – 16 lb·ft.).

3. Hose clamp with torque driver; tighten.

Tighten

• Clamps: 1.5 – 2 N·m (1.1 – 1.5 lb·ft.).

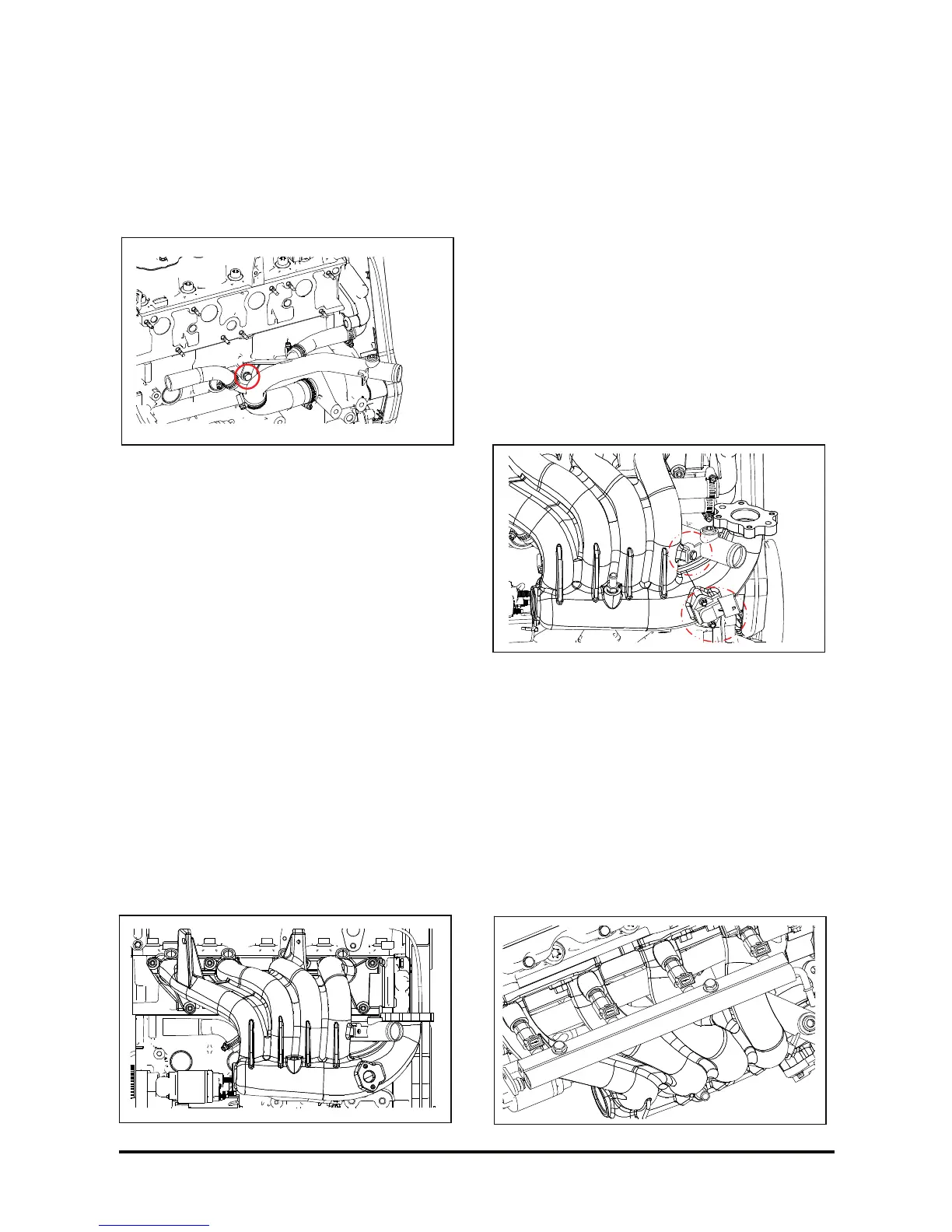

4. A new gasket between intake manifold and

cylinder head.

5. Intake manifold and its attaching nuts, without

tightening.

6. With a 13-mm socket wrench, extension and

proper torque wrench; tighten.

Tighten

• Nuts: 18 – 22 N·m (13 – 16 lb·ft.).

Obs.: Tighten the intake manifold nuts in a

crisscross sequence, from the center to the ends.

7. Put the pipe on the manifold.

8. With a 10-mm socket wrench, extension and

proper torque wrench; tighten.

Tighten

• Bolts: 5 – 6 N·m (3.7 – 4.4 lb·ft.).

9. Insert the TMAP onto manifold with greased o-

ring.

10. With an E-8 socket wrench, extension and

proper torque wrench; tighten.

Tighten

• Bolts: 6– 7 N·m (4.4 – 5.2 lb·ft.).

11. MAP sensor electric connector in the intake

manifold rear area.

12. Insert the fuel rail with injectors in the hole of

manifold and paste oil and grease to o-ring of

injector. (G424FE)

13. With a 12-mm socket wrench, extension and

proper torque wrench; tighten.

Tighten

• Nuts: 18 – 22 N·m (13 – 16 lb·ft.).

Loading...

Loading...