Maintenance

Dräger Polytron 8100 33

6.4 Replacing the sensor

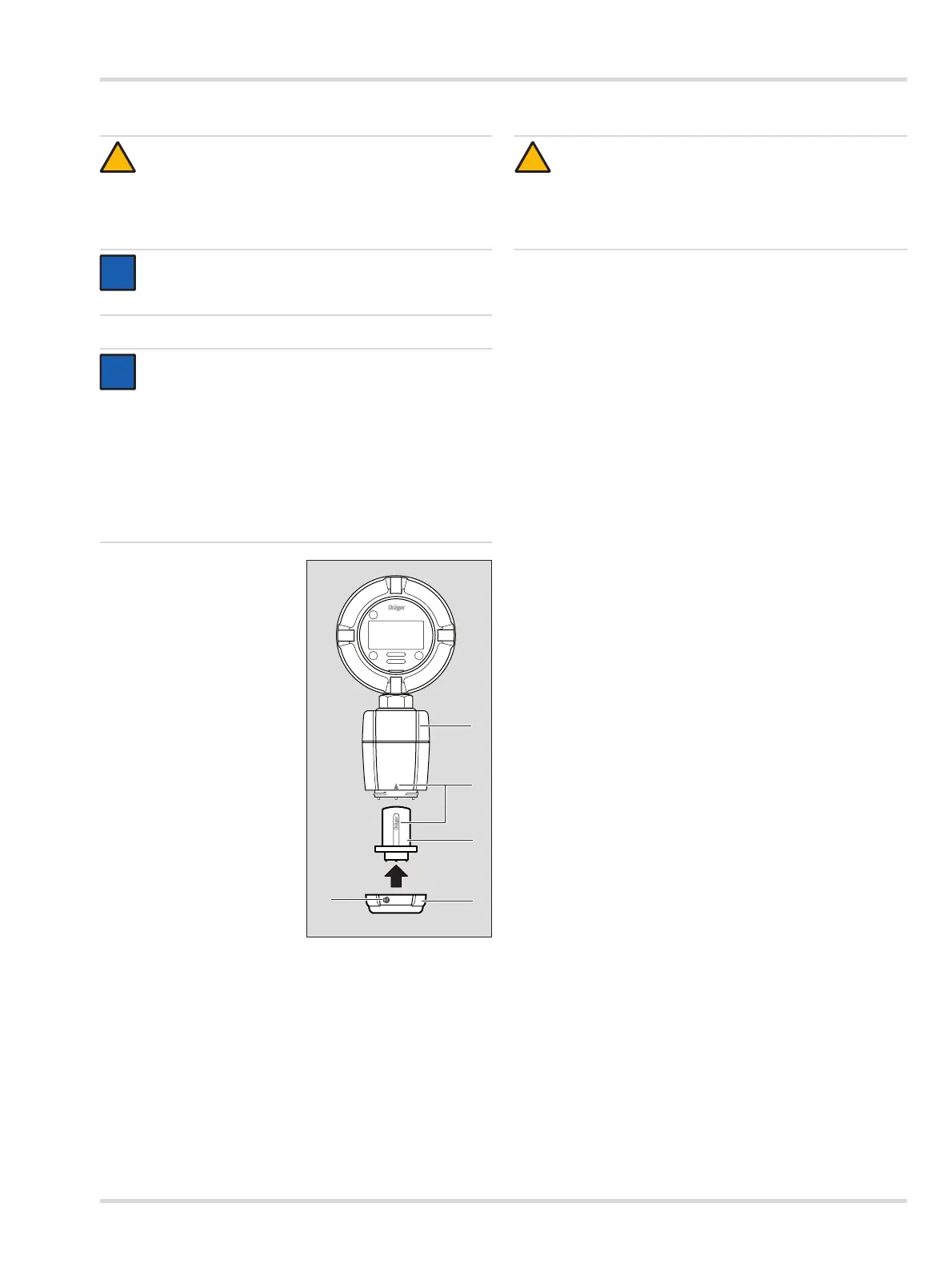

To replace the sensor:

Select Settings > Sensor

> Sensor change and

confirm.

Loosen set-screw (2)

2 mm Allen screw.

Unscrew bayonet ring (3).

Remove sensor from

packaging.

Insert sensor (4) into the

opening. The Dräger logo

on the sensor must point

to the mark on the sensing

head housing (5).

Lock sensor with bayonet

ring.

Tighten set-screw (2).

Mandatory for Zone 22

installations.

If necessary, apply the

label included with the

sensor to the instrument.

This identifies the gas type

from a distance, even if the power has failed.

Calibrate instrument, if necessary (see Section 6.2 on

Page 28).

Check the installation requirements and instrument for SIL

status (see Section 5.6 on Page 18).

6.5 Replacing the main electronics

To replace the main electronics:

Turn off power to the instrument or declassify the area

according to local regulations.

Loosen set-screw and unscrew lid from instrument.

Lift the handle and pull out the bucket with the main

electronics.

Turn bucket over and pull off the power, relay and sensor

connectors.

Replace the main electronics.

Plug the power, relay and sensor connectors back into

appropriate sockets and tighten screws.

Place bucket back into the enclosure.

Screw the lid back on until it is seated (see Section 10.8 on

Page 42) and tighten set screw.

Apply power to the instrument.

Check all settings and parameters.

Calibrate instrument, if necessary (see Section 6.2 on

Page 28).

Check the installation requirements and instrument for SIL

status (see Section 5.6 on Page 18).

CAUTION

Always test a newly installed sensor with target gas to

verify proper operation

If the sensor is replaced, all settings and parameters

must be checked for correctness.

NOTICE

The sensor can be replaced in the hazardous,

classified area, without interrupting the power supply.

NOTICE

If a sensor of the same type (same part number) was

previously installed, the instrument specific

configuration is retained (gas type, measurement

range, test gas, calibration interval, etc.)

Otherwise the factory default settings of the new

sensor (see Instructions for Use for the sensor) are

uploaded and will overwrite the instrument specific

configuration.

This can be prohibited if the sensor lock function (see

Section 5.9.4 on Page 25) is activated.

CAUTION

Always test a newly installed main electronics with

target gas to verify proper operation

If the main electronics is replaced, all settings and

parameters must be checked for correctness.

!

Loading...

Loading...