59

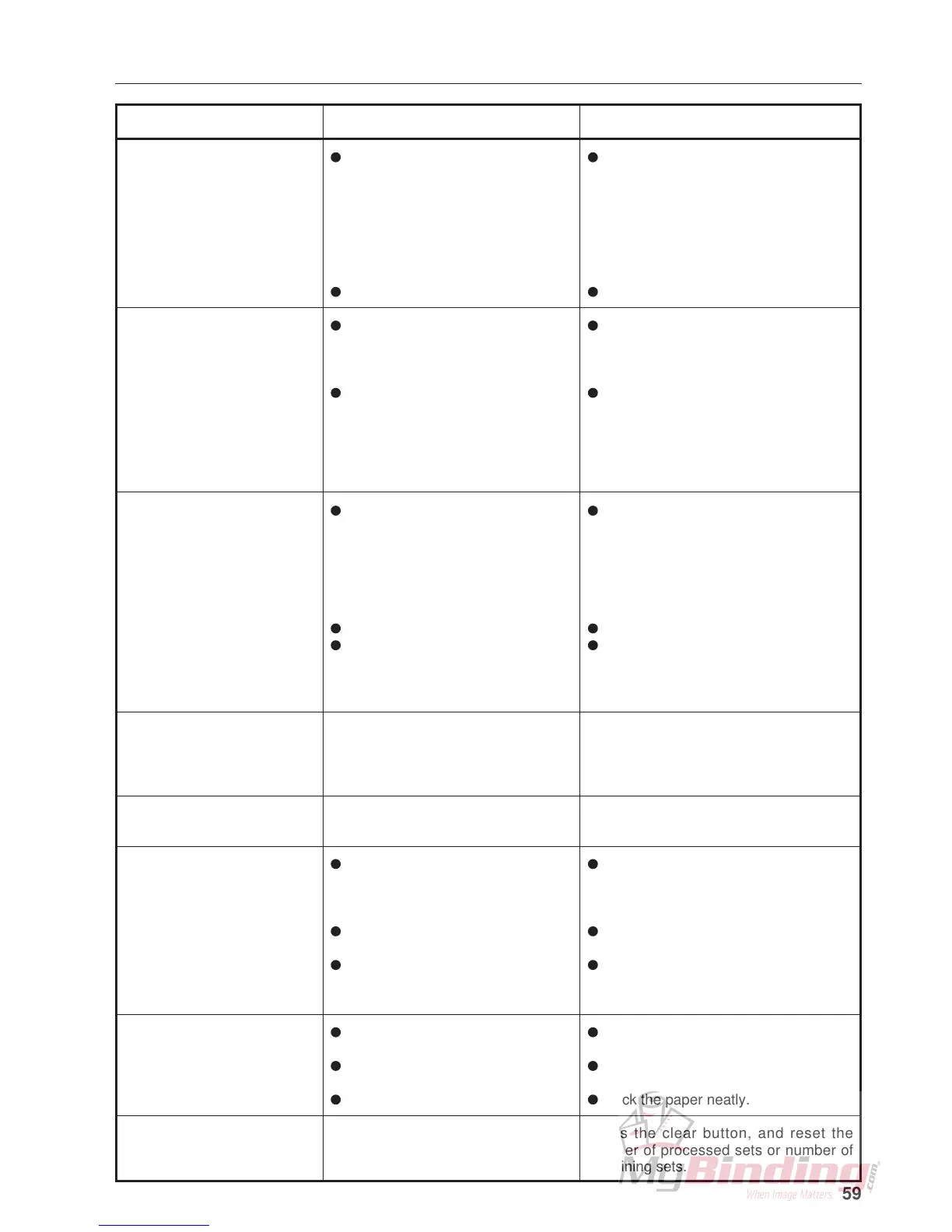

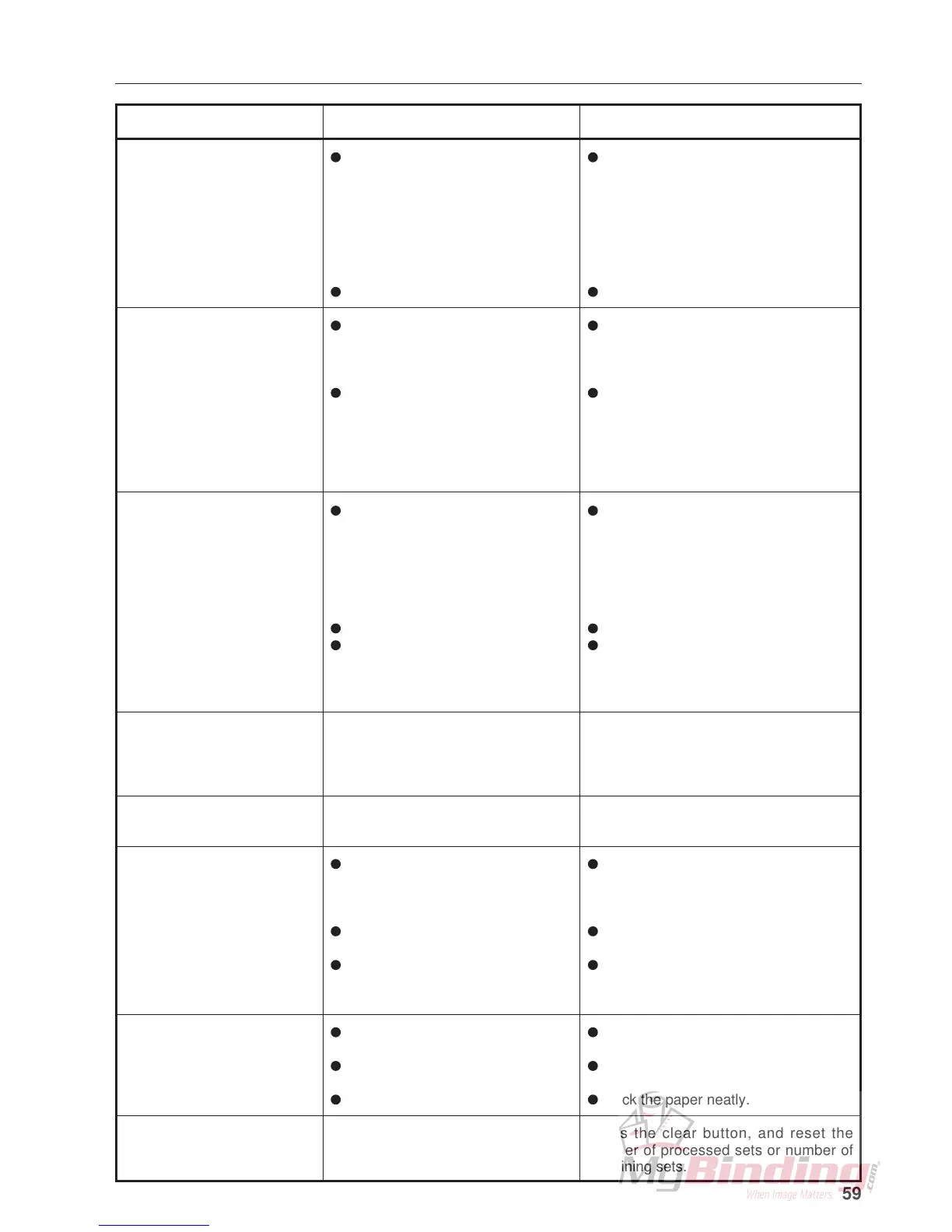

21. TROUBLESHOOTING

Adjust the level sensor, separator air,

and separator of each paper feeder.

(Refer to “15. STACKING PAPER ON

THE PAPER FEEDER A AND

ADJUSTING PAPER FEED” and “16.

STACKING PAPER ON THE PAPER

FEEDER B AND ADJUSTING PAPER

FEED”.)

Flatten curled paper.

Set the paper thickness, detection

range, and detection method

appropriately. (Refer to “13-5. Setting

the Double-feed Detection Sensor”.)

Change the end mark position or the

setting of double-feed detection start

position. (Refer to “8-2. Setting the

End Mark Detection Function” and

“13-5. Setting the Double-feed

Detection Sensor”.)

Adjust the level sensor and separator of

each paper feeder. (Refer to “15.

STACKING PAPER ON THE PAPER

FEEDER A AND ADJUSTING PAPER

FEED” and “16. STACKING PAPER

ON THE PAPER FEEDER B AND

ADJUSTING PAPER FEED”.)

Refer to step 6 in “6. OPERATIONS”.

Set the paper thickness and detection

range appropriately. (Refer to “13-5.

Setting the Double-feed Detection

Sensor”.)

Set the paper thickness and detection

range appropriately. (Refer to “13-5.

Setting the Double-feed Detection

Sensor”.)

Set the remote switch position to the top.

Set whether to use the end mark, paper

face, and position appropriately. (Refer

to “8-2. Setting the End Mark

Detection Function”.)

Enter an end mark in solid printing

using a laser printer.

Prevent paper from being fed crookedly

using the auxiliary stack guide A. (Refer

to “17. AUXILIARY STACK GUIDE A”.)

Adjust the separator air adjustment

knob A to a smaller value.

Adjust the rear guide to the rear end of

the paper.

Stack the paper neatly.

Press the clear button, and reset the

number of processed sets or number of

remaining sets.

Symptom

Cause Remedy

Double-feeding occurs

frequently.

Misdetection of double-feed

Mis-feeding occurs

frequently.

Paper jam detected

immediately after paper feed

Power does not turn ON.

End mark is not read

normally.

Order of sheets becomes

irregular.

Cannot start.

Improper adjustment of paper

feeder.

Paper is curled up.

Double-feed detection sensor

setting is inappropriate.

The printing position of the end

mark is overlapping with the

double-feed detection area.

Improper adjustment of paper

feeder.

Test feeding was not performed.

Double-feed detection sensor

setting is inappropriate.

Double-feed detection sensor setting

is inappropriate.

Remote switch is set to bottom

position.

End mark setting is inappropriate.

End mark is too thin.

Paper is fed crookedly.

Too much separator air A blown

out.

Position of rear guide is

inappropriate.

Paper not stacked properly.

Number of processed sets is the

same as number set, or number of

remaining sets is 0.

Loading...

Loading...