7 | Installation and commissioning

54

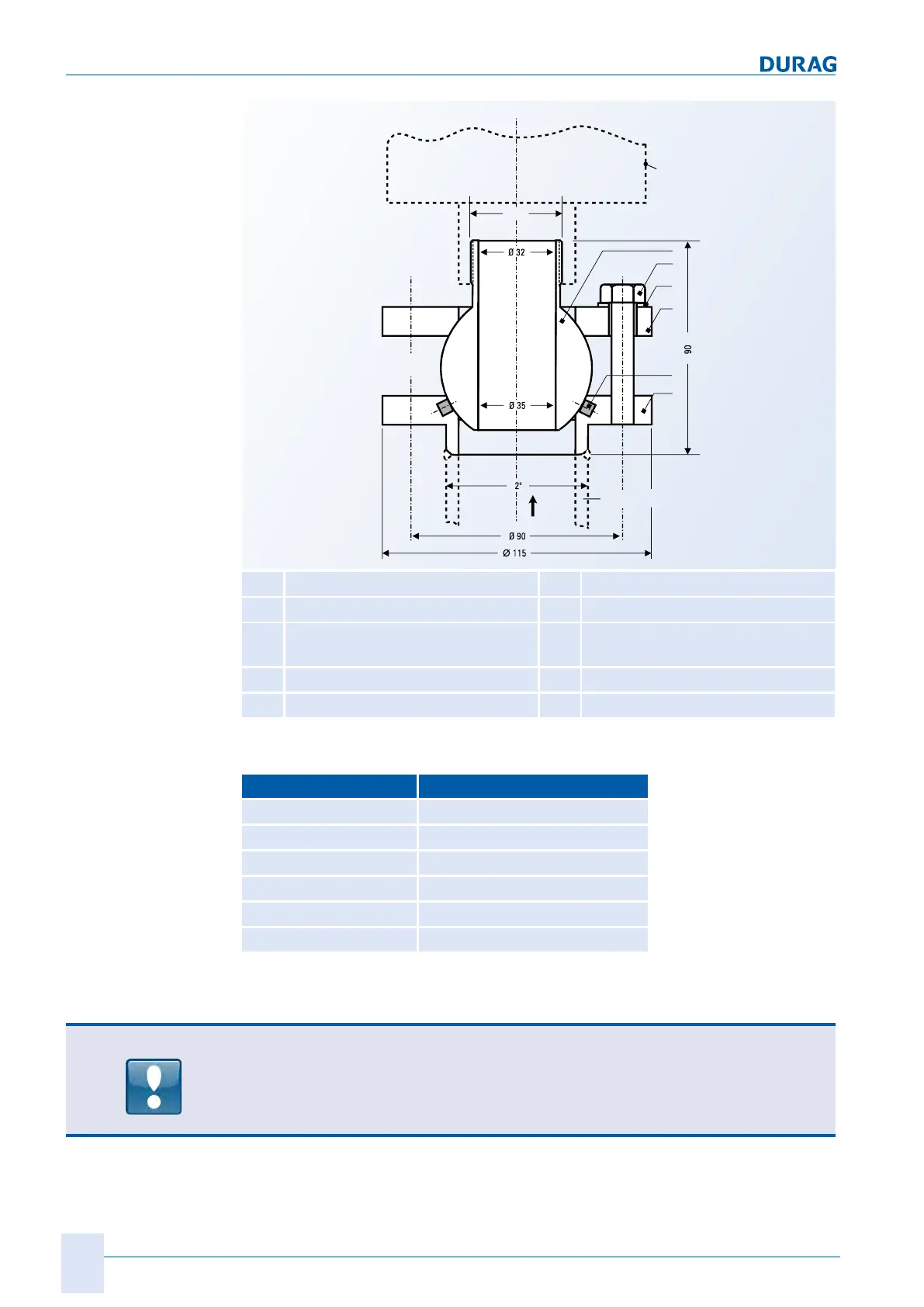

D-LX 201/721

1

Flame monitor

6

Sealing cord

2

Ball joint

7

Welded flange

3

Hexagon screw (3x),tightened to

maximum 20Nm

8

Sighting tube

4

Shim (3x)

9

Flame

5

Flange

Fig.7.2: Swivel mount D−ZS 033−I in installed condition

Component Material (properties)

Welded flange 1.0718, galvanised surface

Flange Al, alloy 230

Ball joint Al, alloy 230

Hexagon screw M10x60, DIN 558

Shim 10.5, DIN 125

Sealing cord Graphite band, asbestos-free

Table7.1: Component specifications

NOTICE

A reliable supply of purge air must be ensured even when the system is stopped. The

purge air serves to protect the system fitted onto the burner. The purge air shields the

components from hot and/or aggressive gases and dust. If the purge air fails, the lens

may quickly become contaminated and the device may overheat due to a build-up of

heat and be destroyed.

Loading...

Loading...