8 | Flame monitor settings

D-LX 201/721

83

NOTICE

The flame monitors (including the Ex versions and all associated components) are

devices with type approvals.

Any changes to to devices with type approvals will lead to the loss of the approval.

Repairs must only be performed by the manufacturer or persons that it has authorised

to do so. This is the only way of ensuring responsible compliance with the

specifications for the type approval of the certifying body.

For safety reasons, flame monitor setting adjustments must only be carried out by ap-

propriately trained personnel.

DURAG offers appropriate courses in this regard.

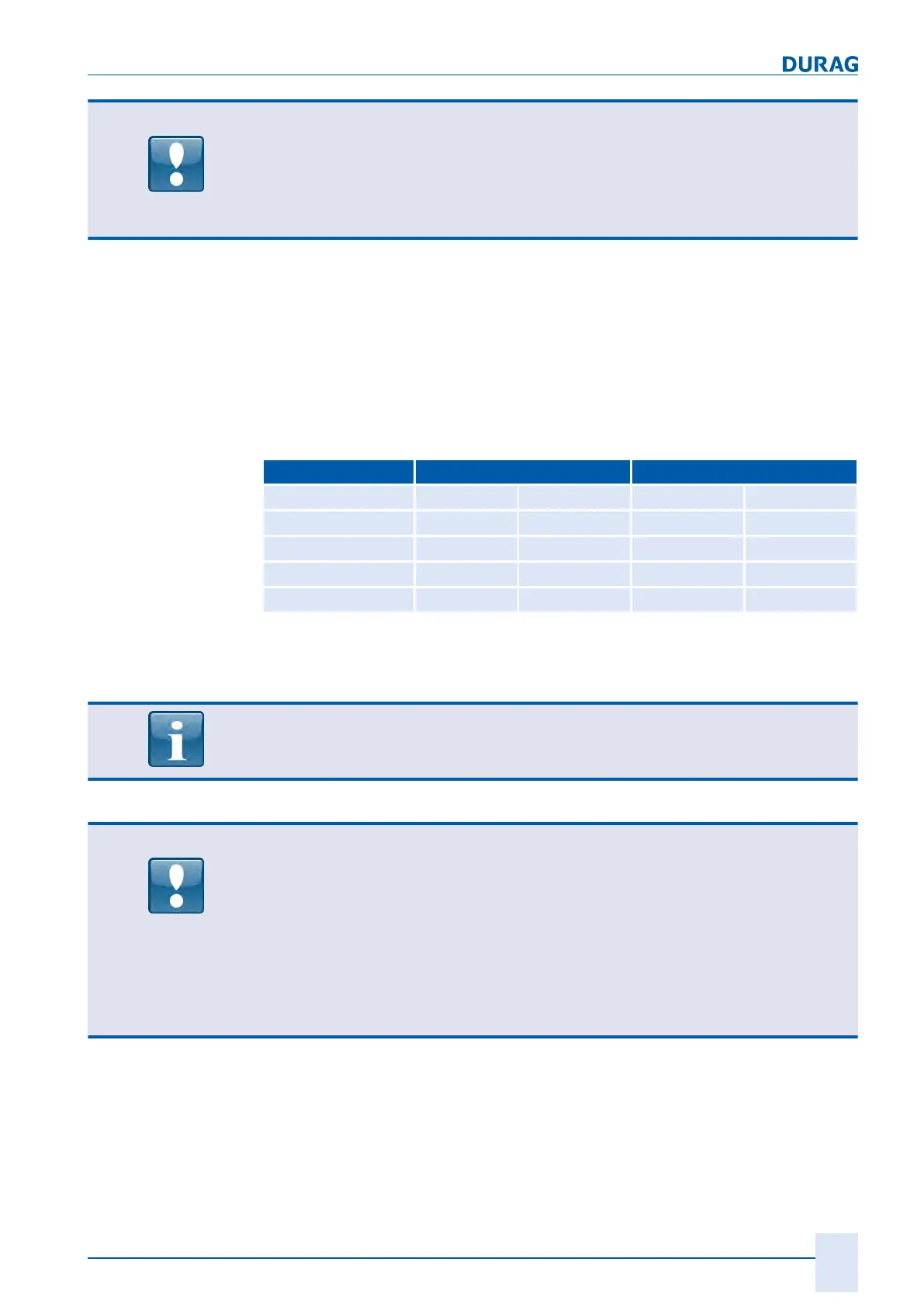

Switch positions 1 to 4 (for the FFDT) of the DIP switches S3 and S4 (see Fig.8.6 in

section 8.4 Setting the threshold for the flicker frequency [}77] and the table

Table8.1) must

not be changed under any circumstances

when setting the switching

thresholds for the frequency. The switch positions for the FFDT on the type label can

be found in the following table for control purposes:

You can set different FFDTs for ranges A and B:

FFDT Range A Range B

DIP position* 1 2 3 4

1 sec off off off off

2 sec on off on off

3 sec off on off on

5 sec on on on on

Table8.2: Switch position of MODE switches S3 and S4 (FFDT)

* The DIP positions 1 to 4 must be set according to the FFDT on the type label! The

FFDT set must be visible from outside!

To avoid an error shutdown, set the MODE switches S3 and S4 to the same setting

within 8 secs.

NOTICE

When re-attaching the cover, make sure that the printed circuit boards slide into the

guide rails correctly and that the connecting lines are not squeezed.

Standard housing:

The seal between the cover and the middle part must fit fully within the middle part.

Tighten the long screws to attach the cover, so that the cover is flushly in position all

the way round the middle part. (max. torque 0.7 Nm).

Ex-housing

For information on closing the housing, see section 7.4.6 Closing housing M4 and S2

(for zone 1/21) [}60]

Loading...

Loading...