The determined acoustic value is inferior to 70 dB (A). No special hearing protection is therefore provided

to the operator in case of continuous use (ISO 3746). However, it remains the responsibility of the user to

evaluate the level of exposure of the operator in accordance with health and safety standards.

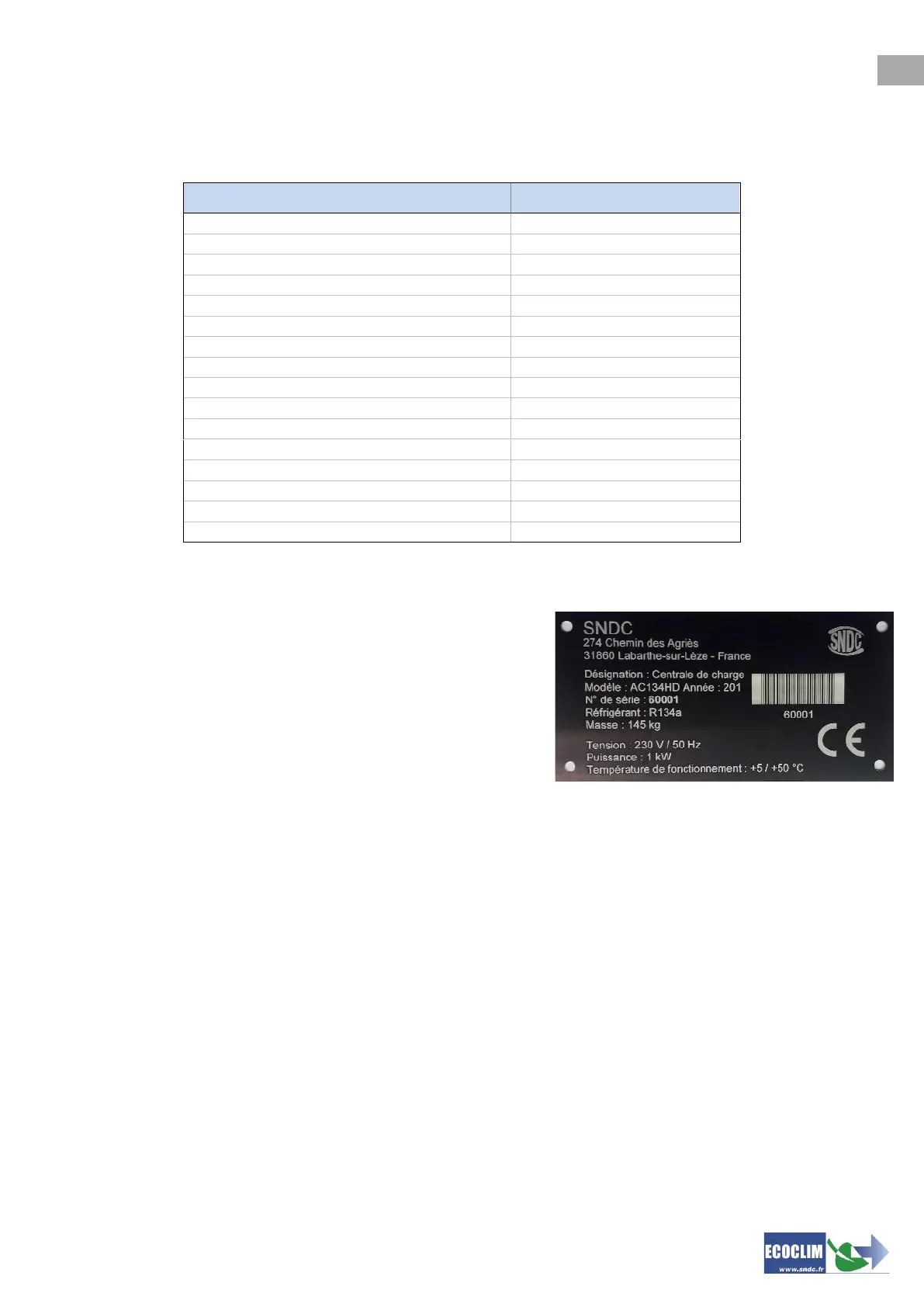

The CE product plate, on the rear of the unit shows:

• Name and address of manufacturer,

• Unit model, year of manufacture and its serial number,

• Refrigerant for which it is designed,

• Net weight,

• Power supply voltage,

• Electric power,

• Operating temperature range.

The unit AC134HD is equipped with the following principle components:

- Digital control panel: It controls all processes via a microprocessor.

- Manometers Ø 80 mm

- High pressure and Low pressure hoses: standard length 5m, equipped with quick connection

couplers R134a.

- Internal refrigerant tank: Max capacity 35 kg, it stores recovered refrigerant before it is reused. It

has a heat resistor controlled by the electronic device, a safety valve and a purge valve for non-

condensable.

- Electric scales for refrigerant: They can weigh up to a maximum of 35 kg of refrigerant with a

resolution of 1g. Precision ± 0,5%

- Electric scales of oil: Resolution 1g; Precision ± 1g.

- Vacuum pump: To eliminate air and humidity from the A/C circuit.

- Compressor: Recovers refrigerant from ECS circuit to store it in the unit's internal tank.

- Filter Drier: Filters out the dirt and moisture from the refrigerant.

- Oil separator: Assures that the oil returns to the unit's compressor.

- Distiller: Separates recovered oil from the recovered refrigerant.

- Graduated plastic container of 500 ml for recovered oil.

Loading...

Loading...