EN_

810G20 - Version V5 – Juillet 2020 P. 77

Traduction de la notice originale

13. Maintenance

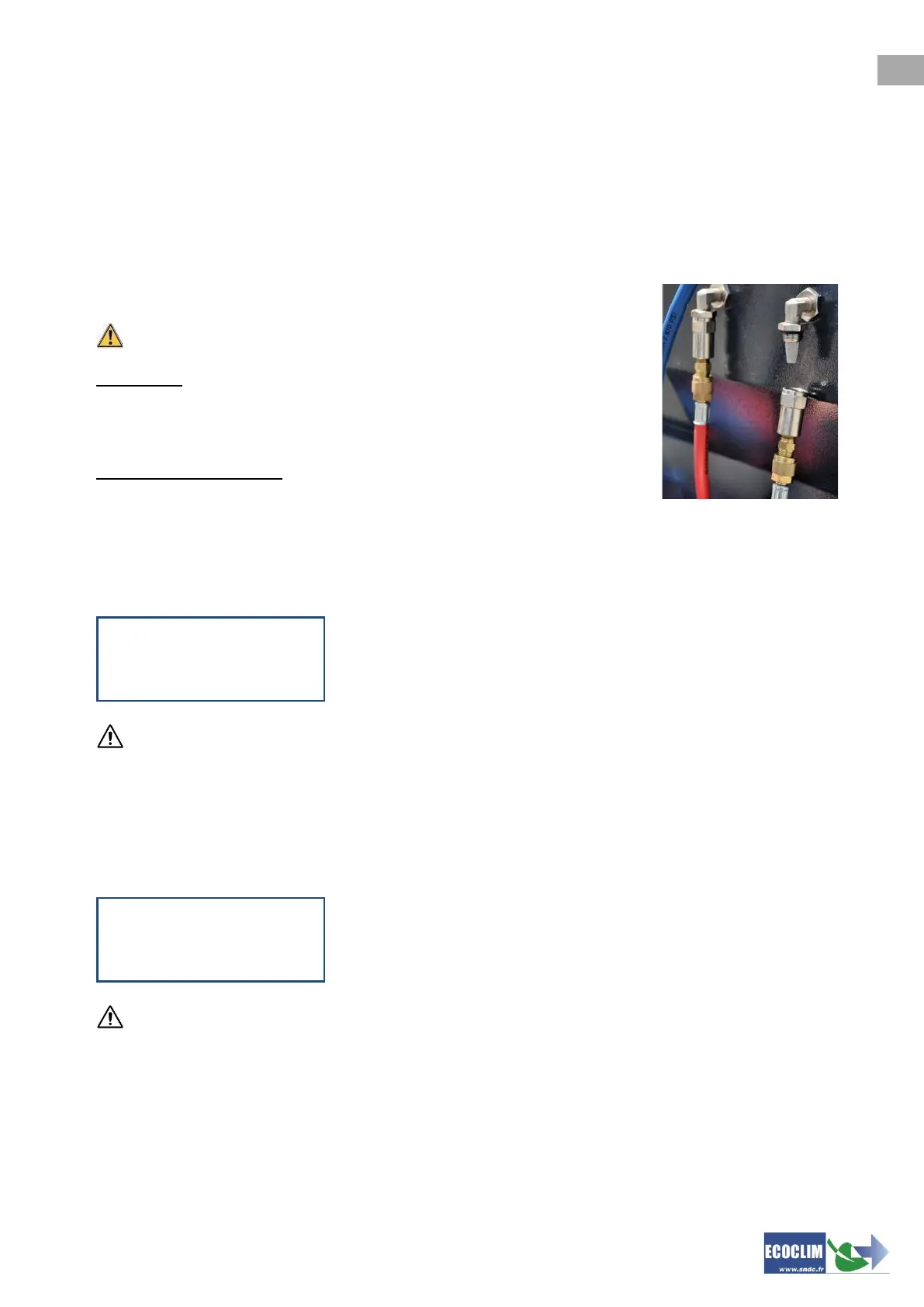

13.1. Cleaning hose filters

The hose filters protect the unit’s internal elements form particles and impurities carried by the recovered

refrigerant.

They should be cleaned as often as possible, and particularly:

- After refrigerant recovery of a polluted ECS circuit,

- Before an ECS circuit charge.

Check that the hoses do not contain refrigerant before

disconnecting. Launch a recovery cycle if necessary.

Procedure:

- Unscrew the bottom part of the filter.

- Clean with compressed air.

- Reassemble the bottom part of the filter.

Filter reference number: 470B24

13.2. Replacing the filter drier

When replacement is required, the screen will display the following message when starting up:

Press ENTER to access homepage.

Refer to chapter 11.2.1 Maintenance information

Maintenance tasks that require opening the unit should only be carried out by an authorised

technician. Contact SNDC.

13.3. Replacing the vacuum pump oil

To guarantee the best performances, vacuum pump oil must be replaced after 600 hours of use. When the

oil change is required, the screen will display the following message when starting up:

Press ENTER to access homepage.

Refer to chapter 11.2.1 Maintenance information

Maintenance tasks that require opening the unit should only be carried out by an authorised

technician. Contact SNDC.

13.4. Yearly maintenance

According to current regulations, a comprehensive maintenance of the unit must be carried out once a

year. Before the due date, the unit displays « Refer to the Maintenance Menu ». Refer to chapter 11.2.1

Maintenance information.

Please check

Maintenance menu

Please check

Maintenance menu

Loading...

Loading...