98

support@edgeovens.com Technical Support: +1 (724) 628 3050

OPERATION

PREVENTATIVE MAINTENANCE

CONVEYOR BELT TENSION ADJUSTMENT

The conveyor belting tension must be adjusted over time. This is a result of natural relaxing of the belt,

caused by general use and heat expansion and contraction caused by the oven cooking process. To make the

task of adjustment easier, as of January 2022, the left hand side (non-drive side) of the conveyor belt frame

incorporates adjustment brackets, which can be adjusted in half (½) inch increments.

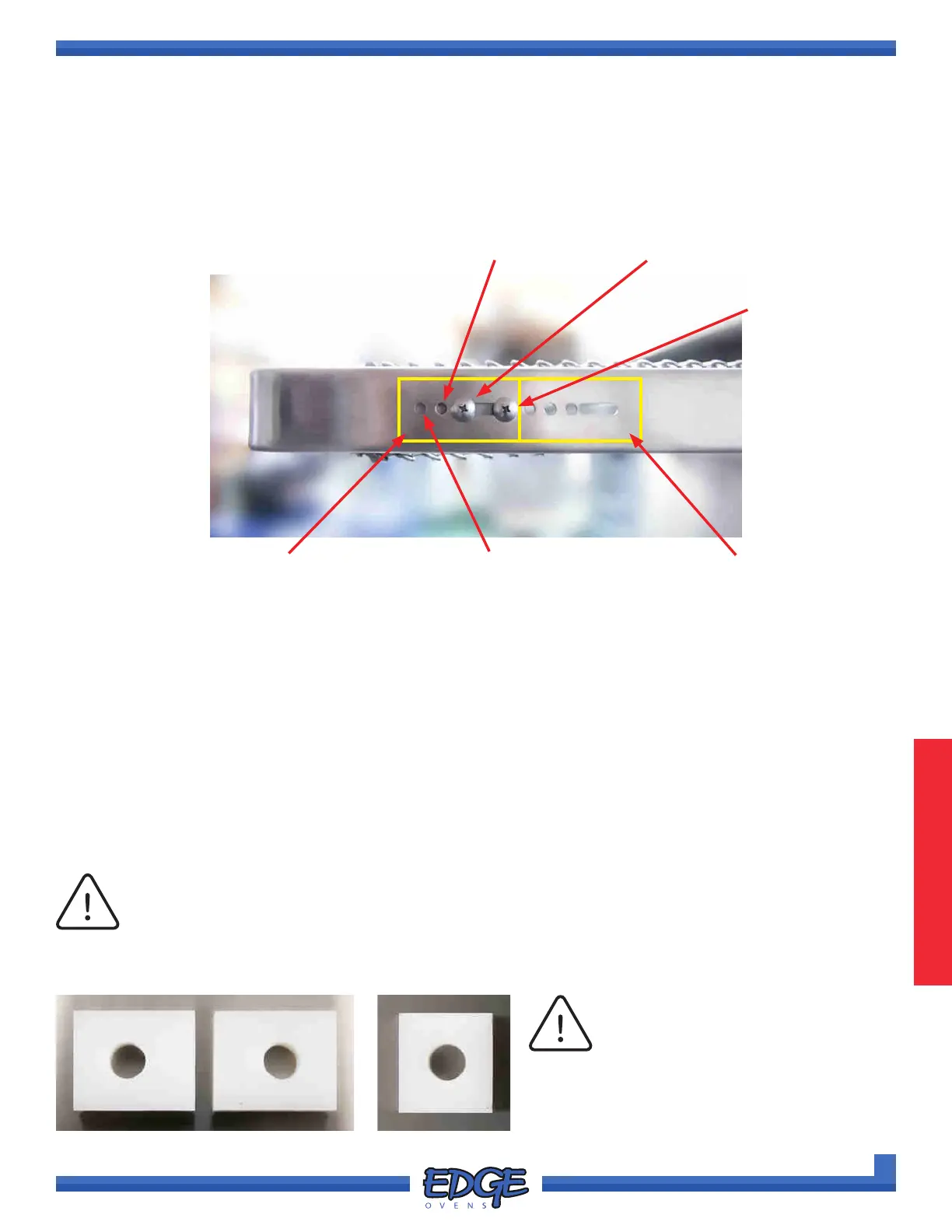

FIGURE 3-27

STANDARD BELT ADJUSTMENT

SLOT AND HOLES

(FACTORY SETTING SHOWN)

[SECTION A]

SPLIT-BELT

ADJUSTMENT SLOT

& HOLES

[SECTION B]

A B

ADJUSTMENT

POSITION 1

ADJUSTMENT

POSITION 2

BOLT A

(LOCKING BOLT)

Adjustment SECTION A is for use with ovens equipped with a standard (non-split) belt. Adjustment SECTION B

is for use with ovens equipped with a split belt.

1. Using a #2 Phillips screwdriver, loosen and remove BOLT A (Locking Bolt). RETAIN for future use.

2. Loosen BOLT B enough so that shaft adjuster plate can be moved. DO NOT remove BOLT B entirely.

3. Repeat this process on the opposing side of the conveyor shaft(s).

4. Push the adjuster plate to the next adjustment position, align and install the previously removed BOLT A.

DO NOT over tighten.

5. Tighten BOLT B to secure adjustment plate position. DO NOT over tighten.

6. Repeat this process on the opposing side of the conveyor shaft(s).

BOLT B

The intention of this system is to reduce the frequency of belt linkage removal, it does not

eliminate link removal. If the adjustment allowance has been expended and the belt has

become slack, the adjustment position must be returned to the most relaxed position (factory

setting as shown above) and belt link removal undertaken, see BELT LINK REMOVAL for

further instructions.

NOTICE

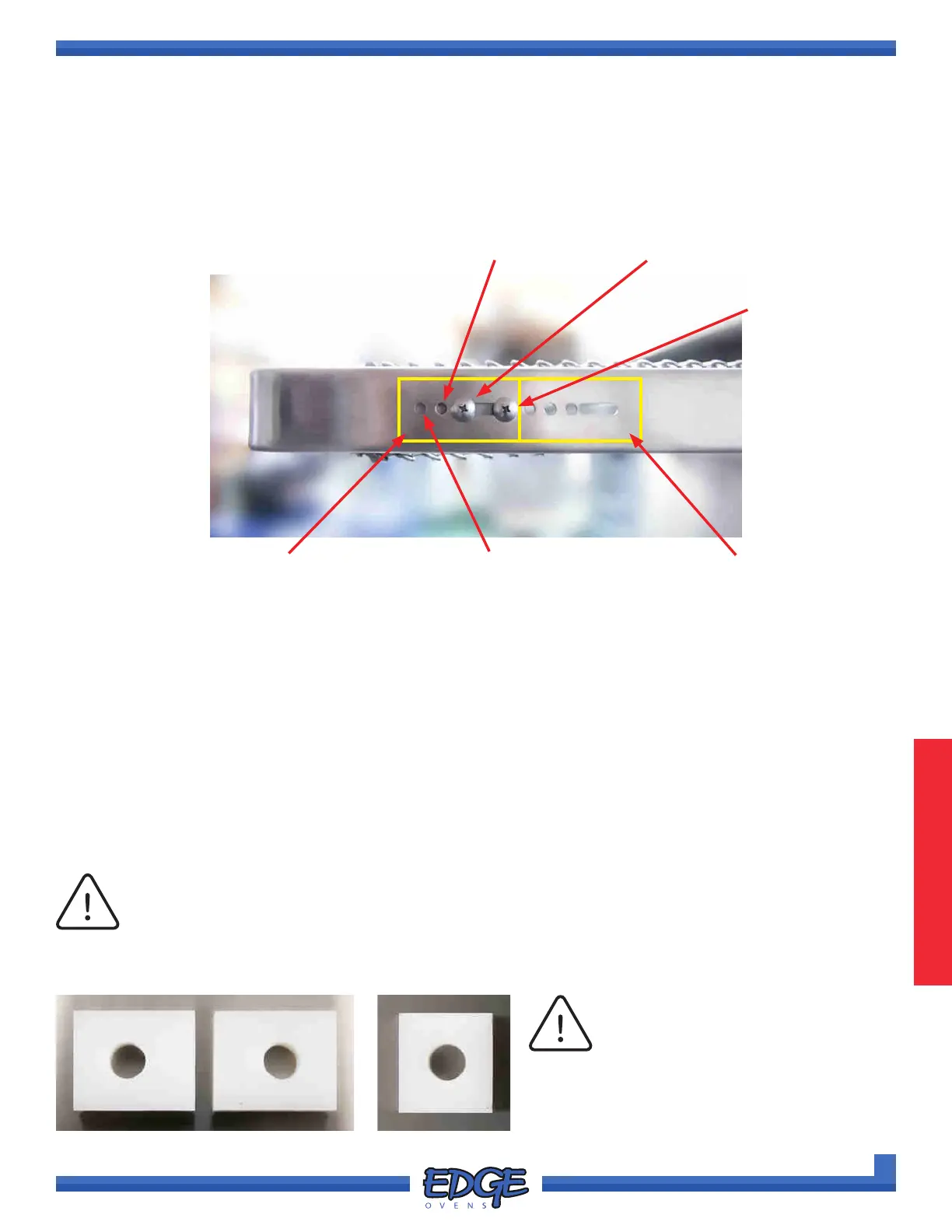

FIGURE 3-28 FIGURE 3-29

SPLIT-BELT conveyors require

two (2) white nylon bushings

per side. These bushings have

wider sections that must face one

another for correct shaft spacing

and chain tensioning.

NOTICE

SPLIT-BELT BUSHINGS STANDARD BELT BUSHING

Loading...

Loading...