9

Electric/Hydraulic TT Thruster 140 - 300

GB

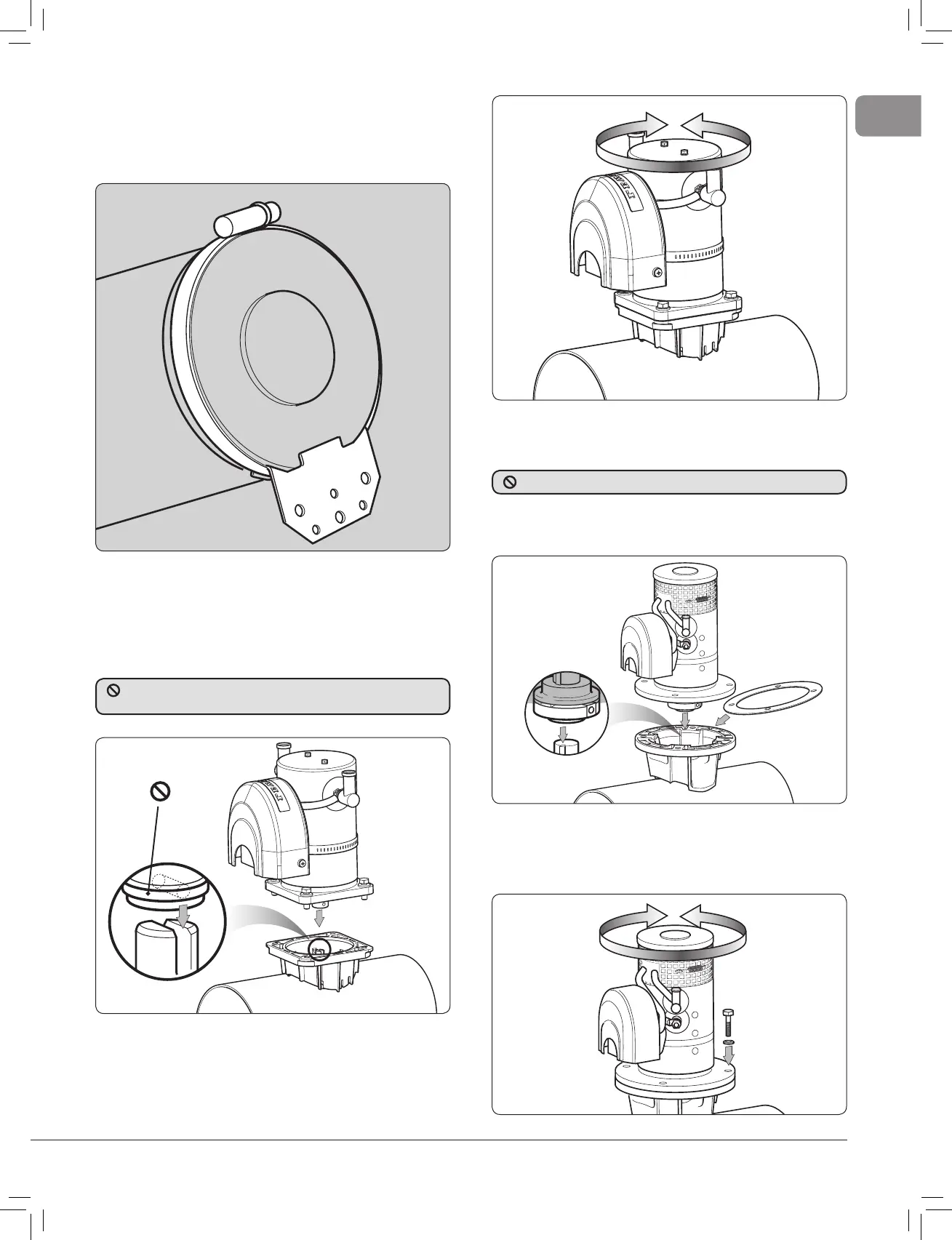

1.8 Electric motor unit support

• If the electric motor is installed more than 30° from the vertical

it MUST be supported and secured to the support with a strap

(not supplied) around the main motor unit.

Fig. 1.8.1

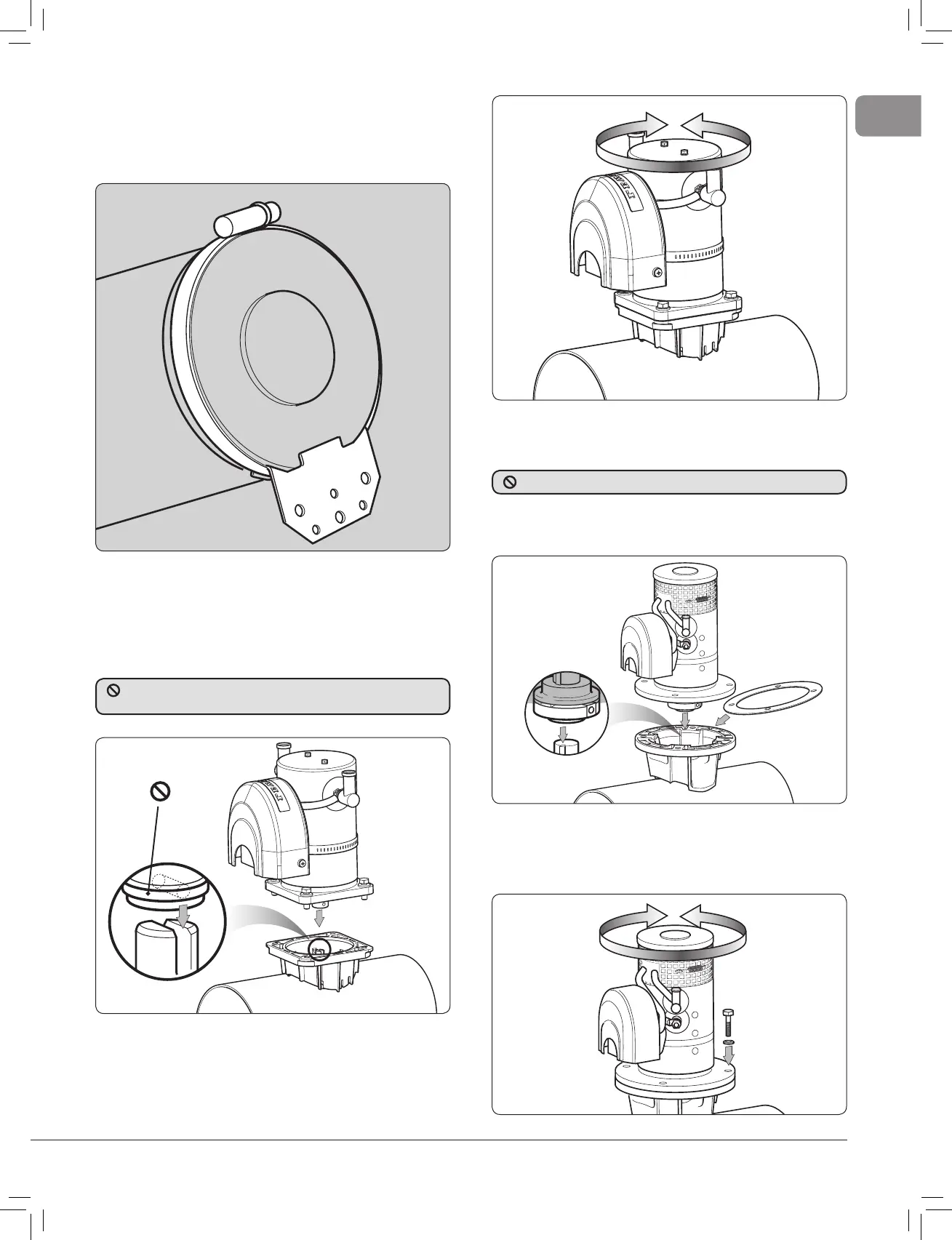

1.10 Installing electric motor

unit model 250TT & 300TT

• Place insulator in between saddle and motor fl ange. Line up

key to coupling keyway.

• Remove drive shaft key retaining tie, grease shaft, slide motor

into position and align holes for most suitable installation and

bolt motor assembly to saddle applying Blue Loctite® 243 to

bolts.

Fig. 1.10.2

Fig. 1.10.1

1.9 Installing electric motor unit

model 140TT & 185TT

• NOTE: Illustrations based on 140TT saddle.

• Align motor drive pin inline with slot in shaft. Apply grease to

hub shaft.

Fig. 1.9.1

• Slide motor into position and align holes for most suitable

installation.

• Bolt motor assembly to saddle and tighten bolts to 20 Nm

(15 lbs.ft) for 140 or 35 Nm (25.8 lbs.ft) for 185. Apply Blue

Loctite® 243 to all bolts.

Fig. 1.9.2

DO NOT REMOVE the drive pin plastic retainer tie on the motor

drive shaft.

Coupling is factory fi tted. DO NOT remove.

Loading...

Loading...