10

Electric/Hydraulic TT Thruster 140 - 300

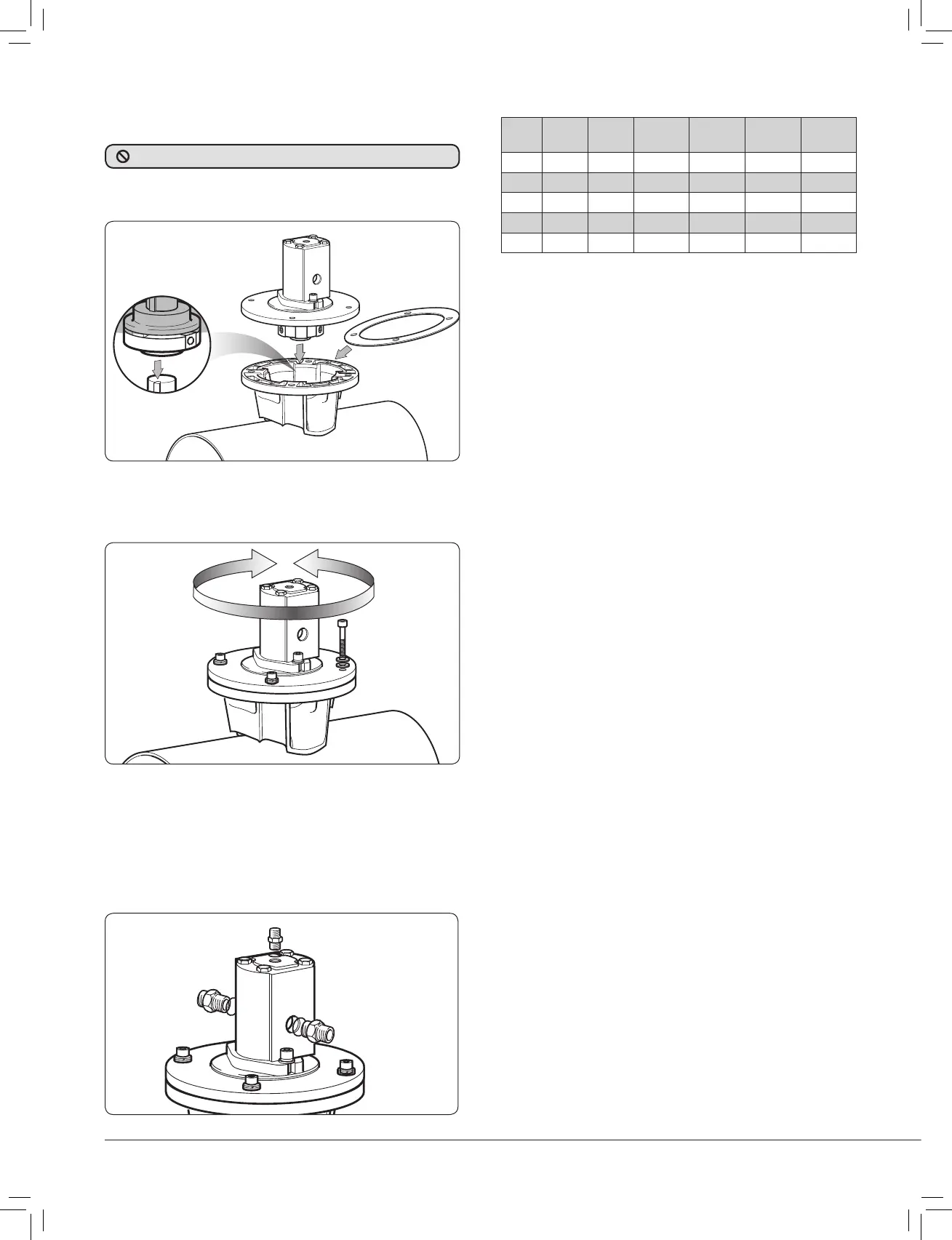

1.11 Installing hydraulic motor unit

model 185TTH to 300TTH

• Place insulator in between saddle and motor fl ange. Line up

key to coupling keyway.

• Remove drive shaft key retaining tie, grease shaft, slide motor

into position and align holes for most suitable installation and

bolt motor assembly to saddle and tighten.

Fig. 1.11.2

Fig. 1.11.1

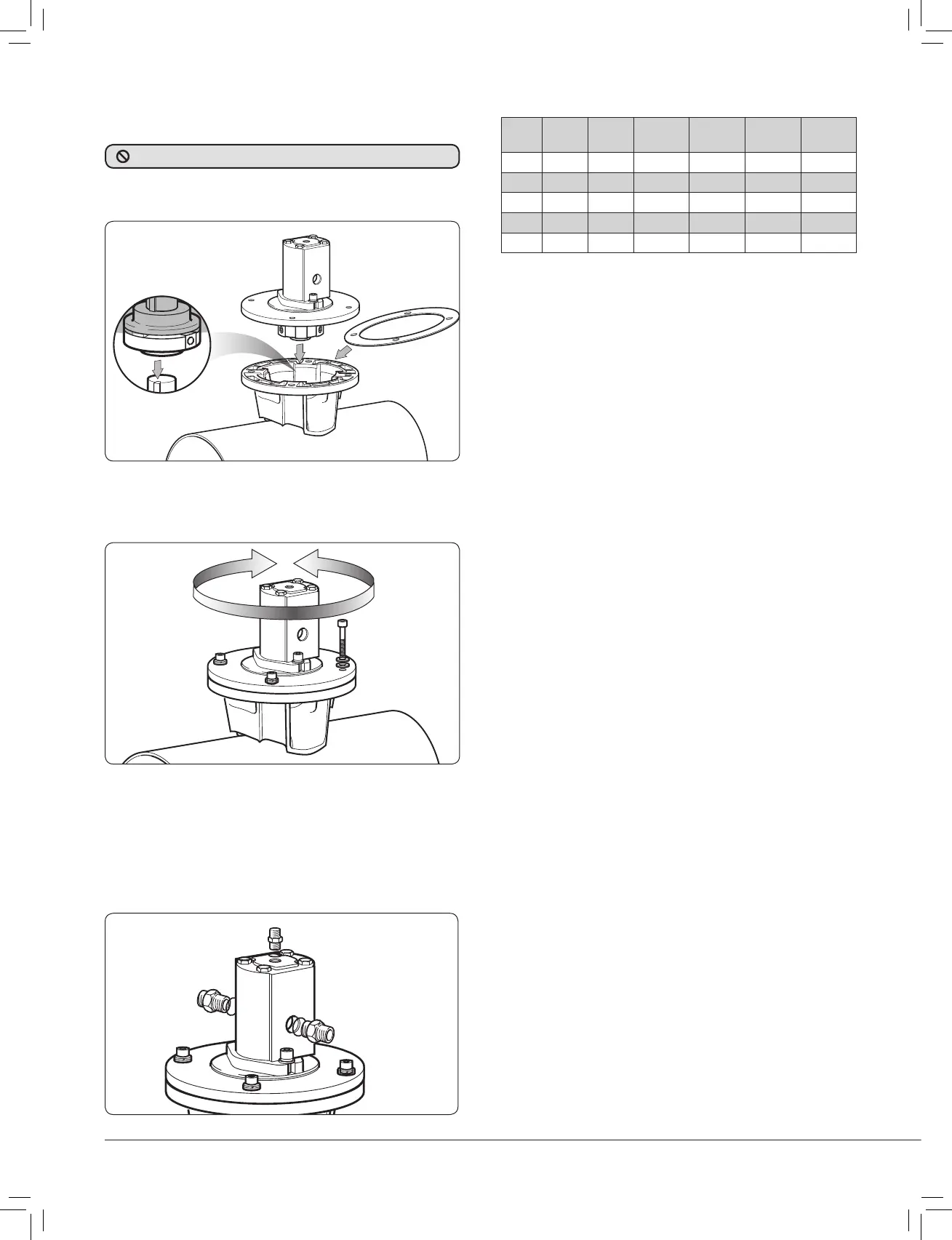

• Motor ports require male/female connectors with correct size

hydraulic sealing washers.

185TT Main ports =

3

/

8

” BSPP.

Main ports =

3

/

4

” BSPP.

Drain ports =

1

/

4

” BSPP.

NOTE: It is advisable to fi t insulated pipe

sections to prevent thruster corrosion.

Fig. 1.11.3

Fig. 1.11.4

Model

Part

No.

Max.

Output

Motor

Disp.

DELTA Flow

Max.

Thrust

185TTH 591820 7 kW 6 cc/rev 210 bar 26 l/min 100 kgf

250TTH 592520 15 kW 26 cc/rev 122 bar 81.5 l/min 200 kgf

250TTH 592521 15 kW 17 cc/rev 190 bar 52.3 l/min 200 kgf

300TTH 593020 22.5 kW 30 cc/rev 182 bar 82.1 l/min 300 kgf

300TTH 593021 22.5 kW 26 cc/rev 210 bar 71.7 l/min 300 kgf

1.12 Final checks - All models

Check list hydraulic

• Check drain line fi tted.

• All fi ttings are tight with seals in place.

• Hydraulic system has been checked and adjusted to correct

pressures and fl ows.

Operation of Hydraulic unit

• Refer to system suppliers instructions.

Check list mechanical

• Check all bolts and nuts are tight.

• Check the propeller/s are correctly installed and the nuts

tightened.

• Check the motor control box cover is in place.

• Check the propeller/s can be turned - before working on unit

check battery switch is off or remove the fuse.

NOTE: Saddle and motor are

fi rmly seated on the tube.

Coupling is factory fi tted. DO NOT remove.

Loading...

Loading...