17

Electric/Hydraulic TT Thruster 140 - 300

GB

4. Servicing your thruster

4.1 Service schedule

NOTE: Thrusters are more likely to attract ‘debris’, so it

is necessary to regularly check the tunnel.

New install:

• The anode should be checked after approximately 3 - 4 months

to gauge an appropriate replacement schedule. .

At the annual boat service:

• Remove any debris from tunnel, propeller and hub.

• Replace the anode.

• If the propeller is damaged or heavily contaminated, replace

it, best to be safe.

• Inspect motor, ensure all leads are still tight.

• Check all bolts and nuts are to correct torque.

• Check the motor assembly is dry and that the compartment

is water tight.

• Check and clean out thruster compartment.

• Apply grease to exposed thruster seal and shaft.

• If hub is removed the tunnel gasket must be replaced.

Electric:

• Inspect electric motor, ensure all leads are still tight.

• Brush out carbon dust from top of electric motor especially

on aluminium boats. Recommend qualifi ed electrician.

Hydraulic:

NOTE: Refer to hydraulic system

supplier for service requirements.

4.2 Changing drive pin 140TT or 185TT

• Cut cable tie on shaft - (If Fitted)

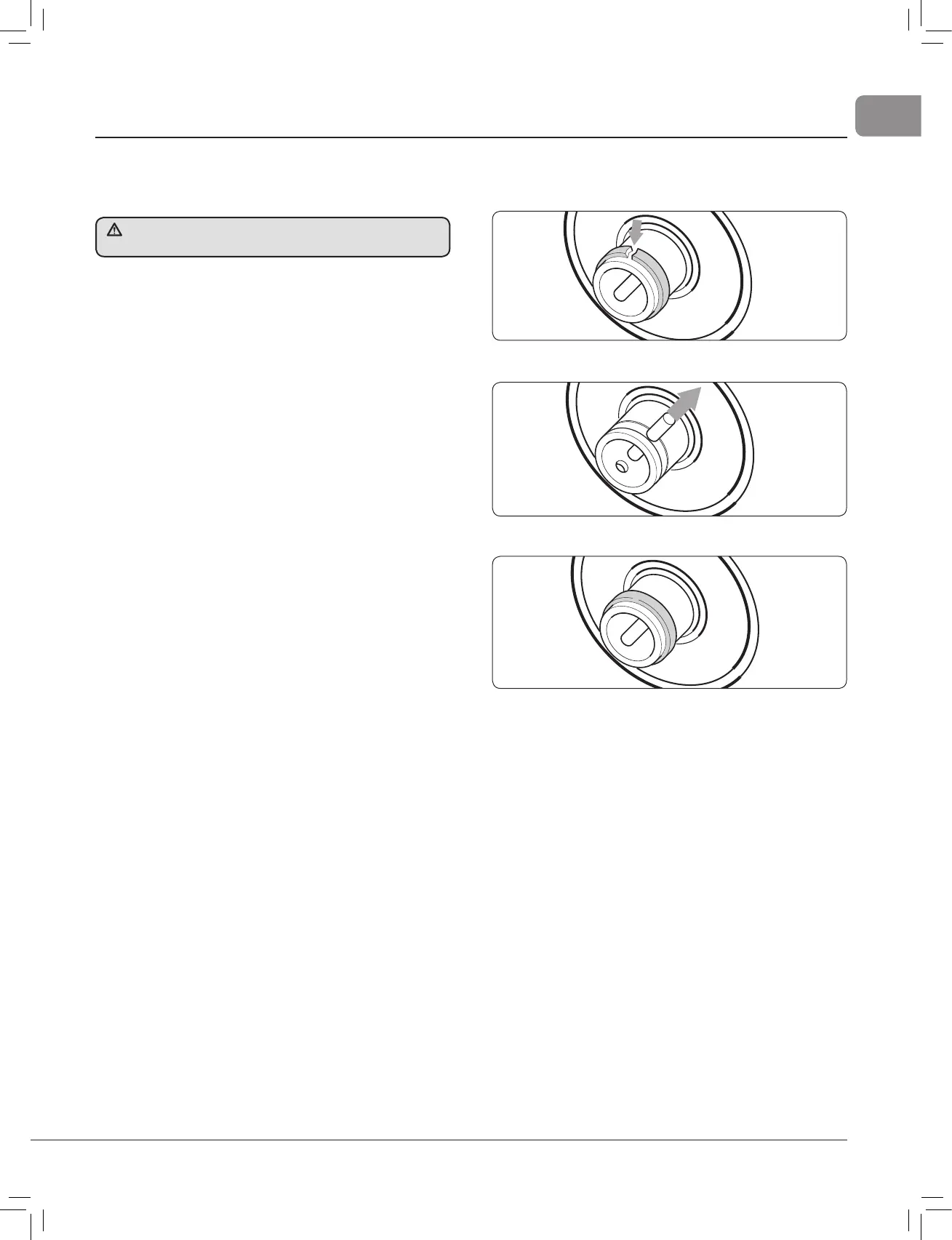

Fig. 4.2.1

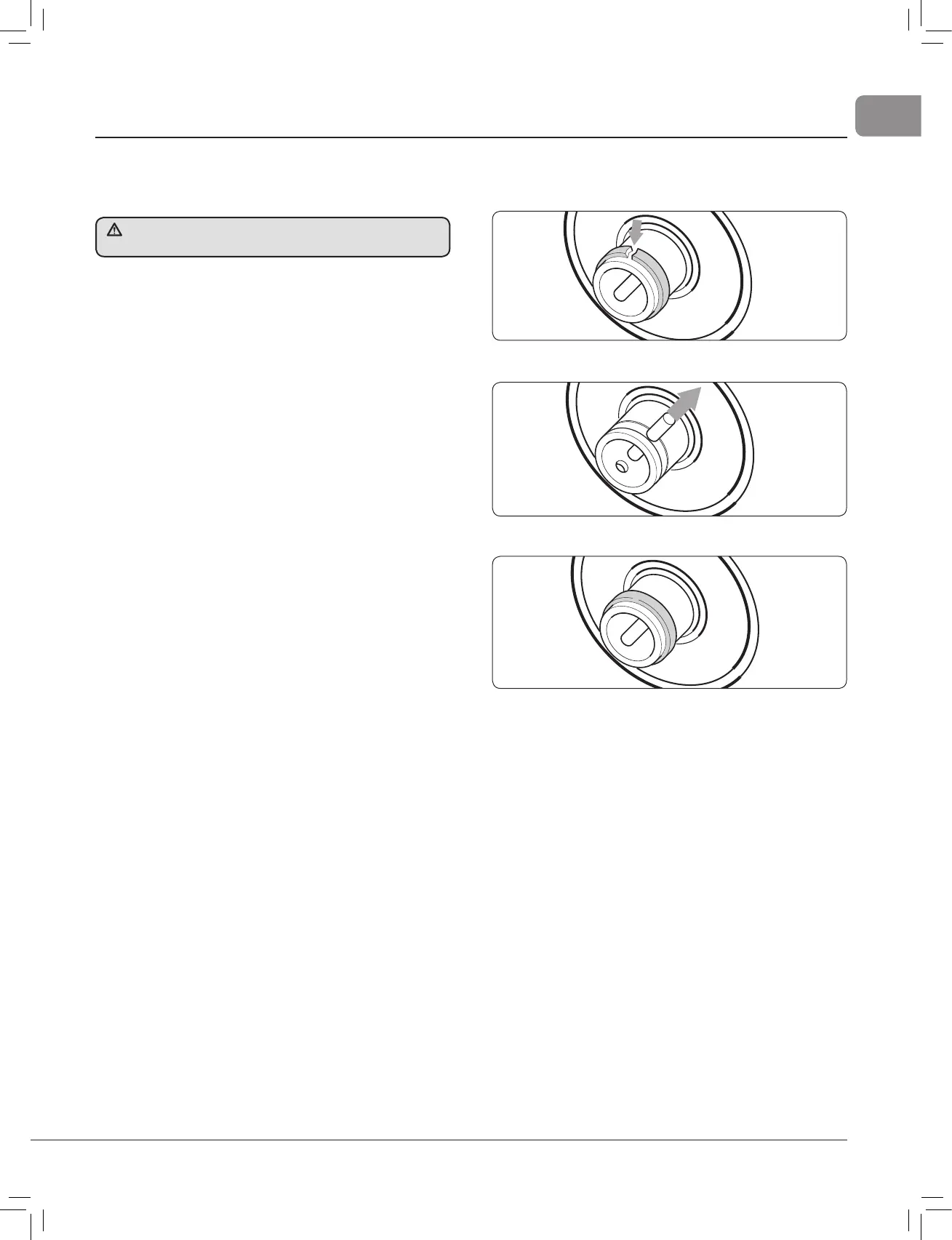

Fig.4.2.2

Fig. 4.2.3

• Punch out pin parts.

• Tap in new pin and secure with new plastic cable tie.

eht evomer ro ffo si hctiws yrettab kcehc tinu no gnikrow erofeB

fuse.

Loading...

Loading...