14

Electric/Hydraulic TT Thruster 140 - 300

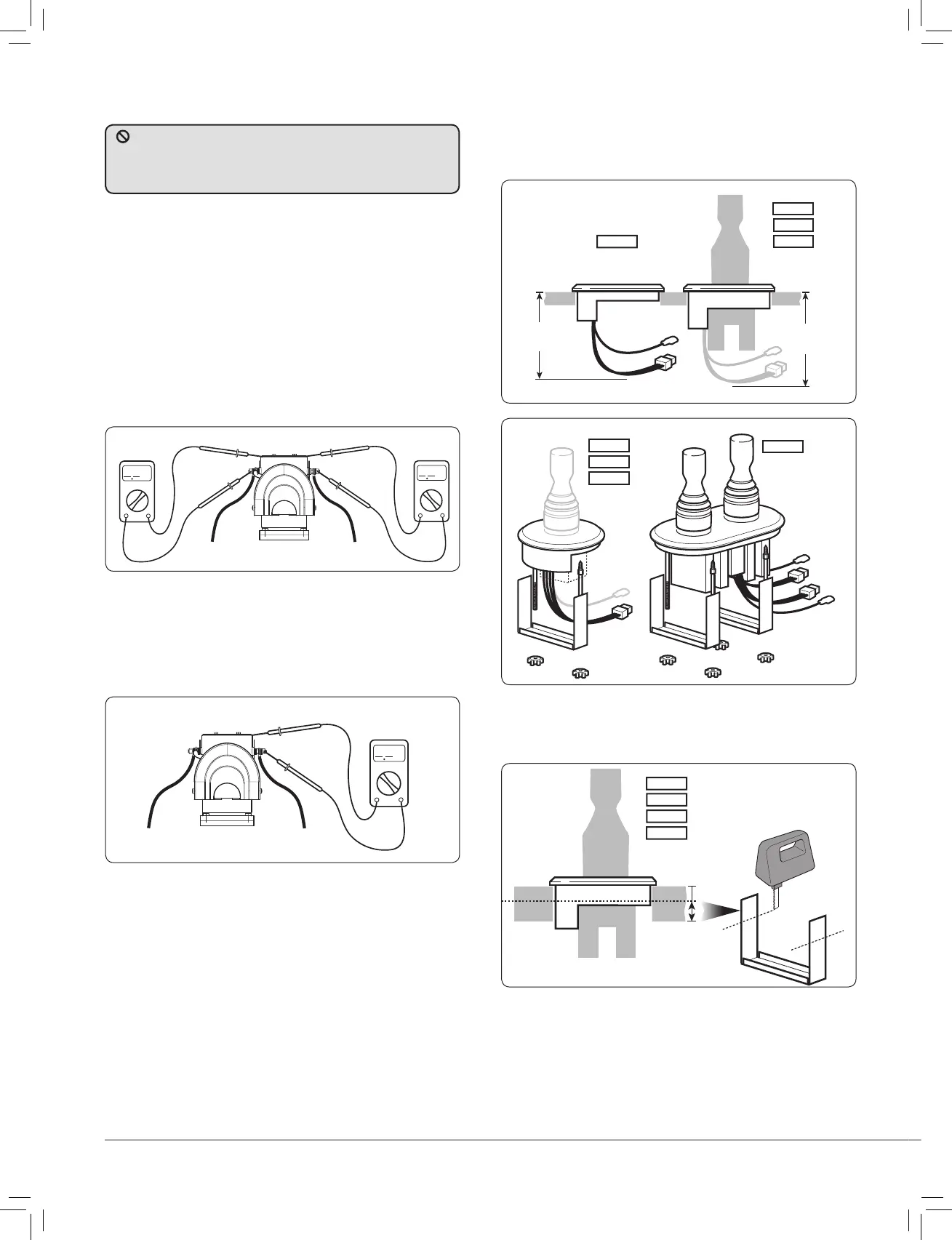

2.8 Installing control panel - all models

• A 63.5 mm (2

1

/

2

”) hole saw is required. Ensure there is

suffi cient depth for the control panel and access for the switch

leads and plug (see saw template).

Fig. 2.8.1

• The panel has an integral seal and can be clamped from the

rear or with the bezel from the top. Trim clamp depending on

panel thickness.

Fig. 2.8.2

589002

589003

589004

589001

589002

589003

589004

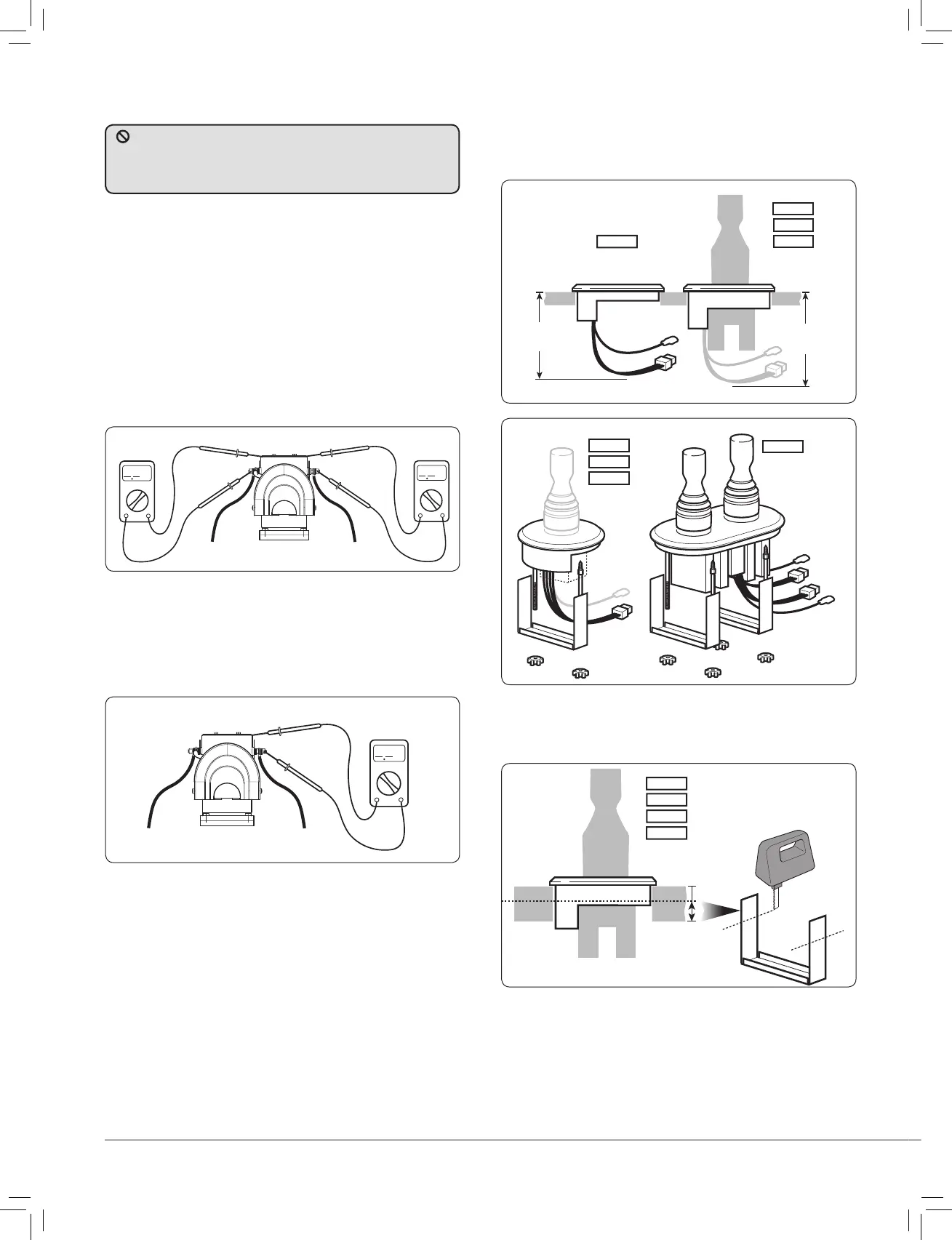

2.7 Electrolytic test

• Test 1. Fig.2.7.1

With the negative not connected and the positive cable

connected but with battery switch off or fuse removed. Use a

continuity tester to check for a connection between the –VE

stud and motor body and also between +VE stud and motor

body. In both cases the meter should give no indication of an

electrical connection.

If a connection is measured between the +VE stud and the

motor body, check installation for cables or wires touching

the assembly or for damage to assembly.

If a connection is measured between the –VE stud and the

motor body, remove any bonding straps attached to the

assembly and check as before.

Fig. 2.7.1

Fig. 2.7.2

• Test 2. Fig 2.7.2

With the battery applied: Use a voltmeter to test the

voltage between the –VE motor stud and the thruster

motor body. If the supply voltage (12 V/24 V)

is measured, disconnect power immediately and inspect the

assembly for faulty installation or damage.

To prevent electrolytic corrosion or faults, the thruster motor

body and assembly MUST remain isolated from any power supply

or grounds. The installer can check for this using a multimeter in

the following ways.

Fig. 2.8.3

589001

589002

589003

589004

589001

Loading...

Loading...