12

Electric/Hydraulic TT Thruster 140 - 300

2.3 Typical electrical layout

models 250TT & 300TT

•. If the thruster operates in an opposite

direction to the control panel, swap the

white and violet wire connections on

the contactor coils.

NOTE: Automatic switch (if

fi tted).Main power is switched

on when panel is switched on.

MOTOR

FUSE

BATTERY

BLACK

BOX

CONTROL

BOX

+VE

–VE

BATTERY SWITCH

OR

AUTOMATIC BATTERY

SWITCH 589034

(If fitted)

RED

VIOLET

WHITE

RED

THERMAL

SWITCH

CONTROL BOX

COVER

REMOVED

TO

CONTROLS

BLACK

BOX

BLACK

(POSITIVE) STUD*

* Solenoid

appearance may differ.

Fuse 5 A

5x20 mm

Fig. 2.3.1

Fig. 2.41

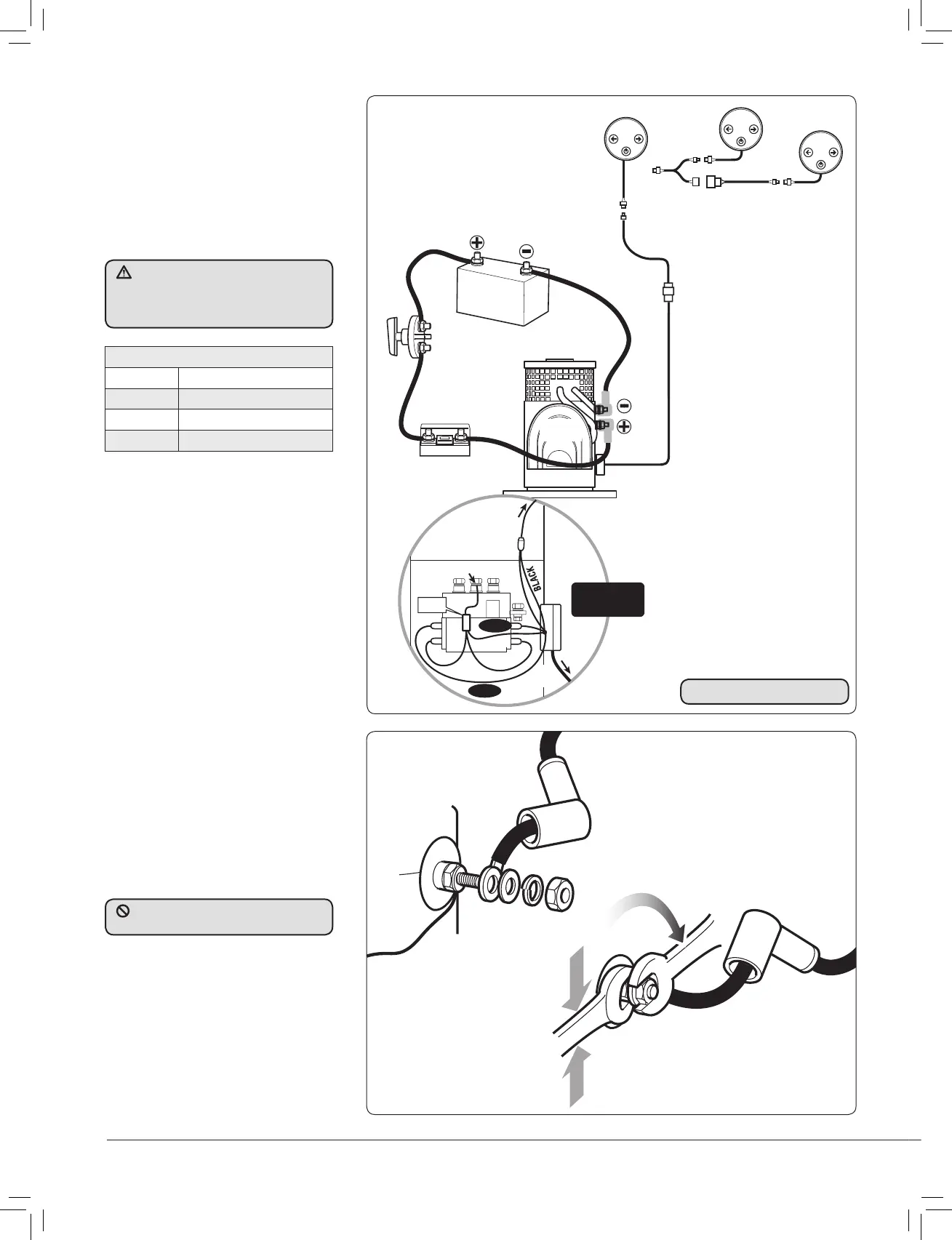

2.4 Electric motor

terminal connections

• Terminals must be correctly clamped

to motor studs. Use a pair of spanners

- the one nearest motor to stop rotation

of the stud.

• Spanner sizes are 13 mm for 140TT and

17 mm for 185TT - 300TT. Tighten the

bolts to 20 Nm (15 lbs.ft).

Loom Wiring

Red

+VE

Blue

Thrust port switch

Grey

Thrust starboard switch

Black

–VE

Negative Switching

NOTE: For dual thruster

controls see stern thruster

manual included in sternkit

or on www.lewmar.com

It is vital that the positive battery

lead is connected to the positive motor

terminal or damage to the electronics

will occur.

DO NOT overtighten electric motor

terminal nuts.

Loading...

Loading...