COMMISSIONING

38/64

EN

5.5.1 Burner start

Before starting the burner, draw oil in until the lter is completely lled. Then start the burner by

creating a heat demand on the boiler (refer to boiler installation manual). Open the bleed screw

on the oil lter to allow the oil line to bleed fully during the preventilation phase. The negative

pressure (vacuum) must not fall below 0.4 bar. Close the bleed screw when the lter is completely

lled with oil and oil is owing out without bubbles. Boiler has to maintain in operation at least 15

min. or reach a steady condition of operation, then check the combustion values.

5.5.2 Burner adjustment

Use the pressure regulator to adjust the oil pressure in accordance with the table (tab.1). Monitor

the combustion values continuously as you do so (CO, CO

2, smoke test). Adjust the airow

gradually if necessary. Operating on air ap setting.

5.6 Oil pressure setting

5.6.1 Oil pressure setting

The oil pressure, and therefore burner output, is adjusted using oil pressure regulator (7), see

“Fig. 34”, on the pump.

Sequence to adjust the oil pressure:

– connect a pressure gauge at point (8).

Turn the regulator screw (7) to:

– right: to increase pressure.

– left: to reduce pressure.

– verify the correct pressure with the pressure gauge.

At the end of adjustment.

– to disconnect the pressure gauge.

– to tight the plug (8).

5.6.2 Checking negative pressure

The vacuum gauge for checking negative pressure must be connected to point (4). Maximum

permissible negative pressure is 0.4 bar check the oil supply in case those pressures cannot be

achieved. At higher negative pressures, the fuel oil gasies, which causes pump cavitation in the

pump and ultimately leads to pump damage.

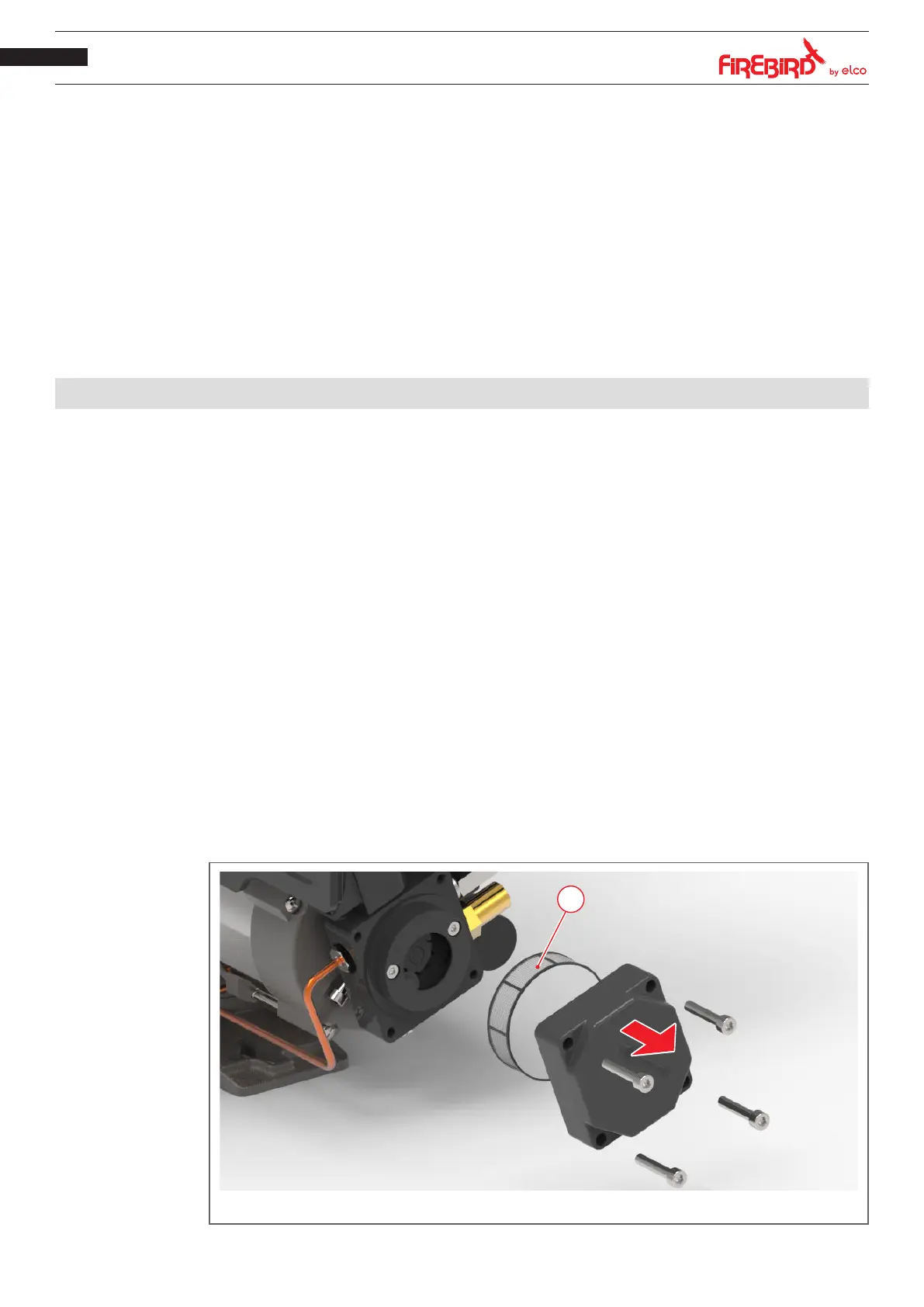

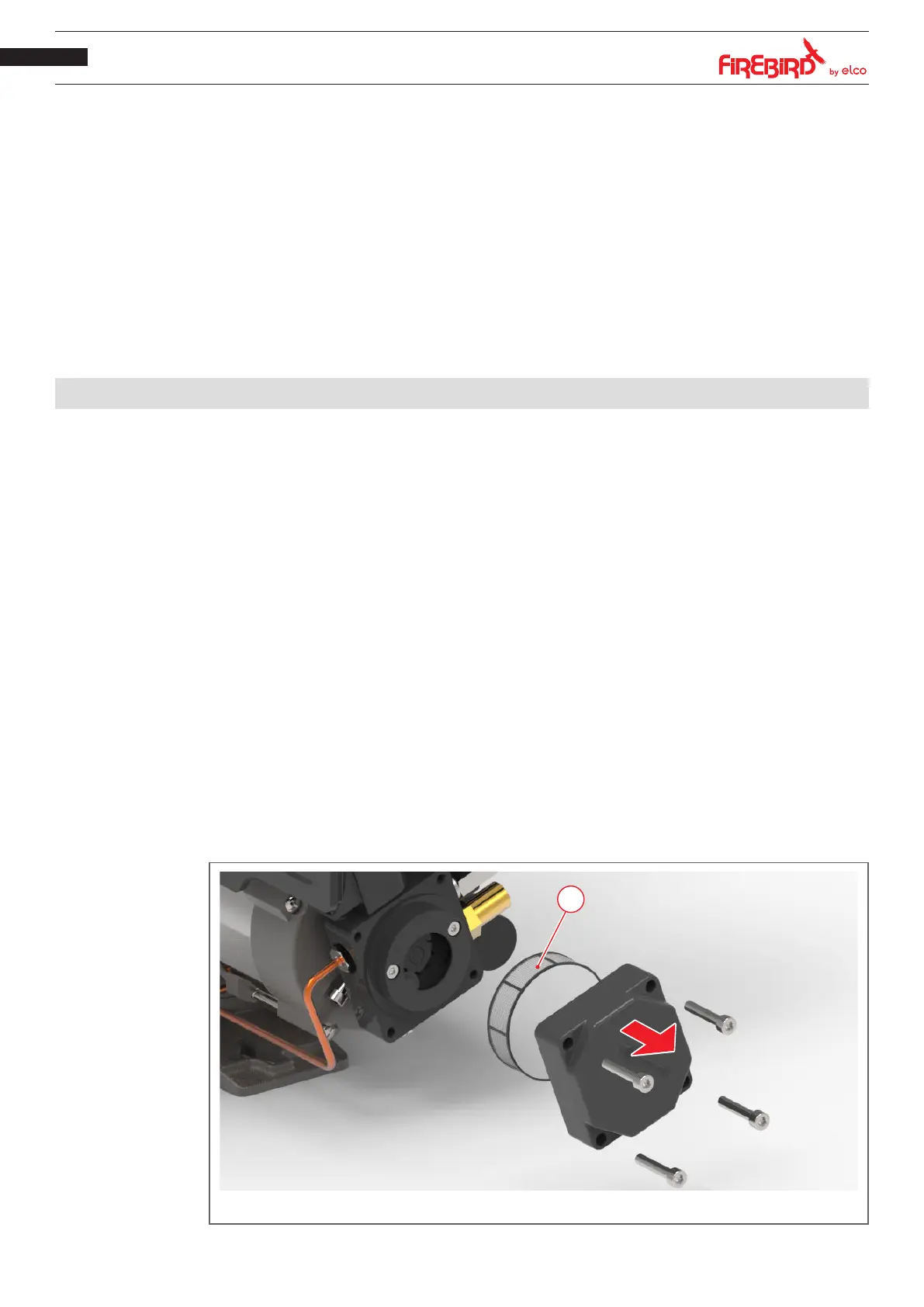

5.6.3 Cleaning the pump lter

To be able to clean the lter (H), it is necessary to remove the pump cover.

Check the pump cover seal and replace the gasket if necessary.

H

Fig. 35

Loading...

Loading...