DOC. NO. 5956.573.05 P. 7 9 / 8 8

Electrolux

EFS - Dishwashing Systems Platform

Electrolux Professional

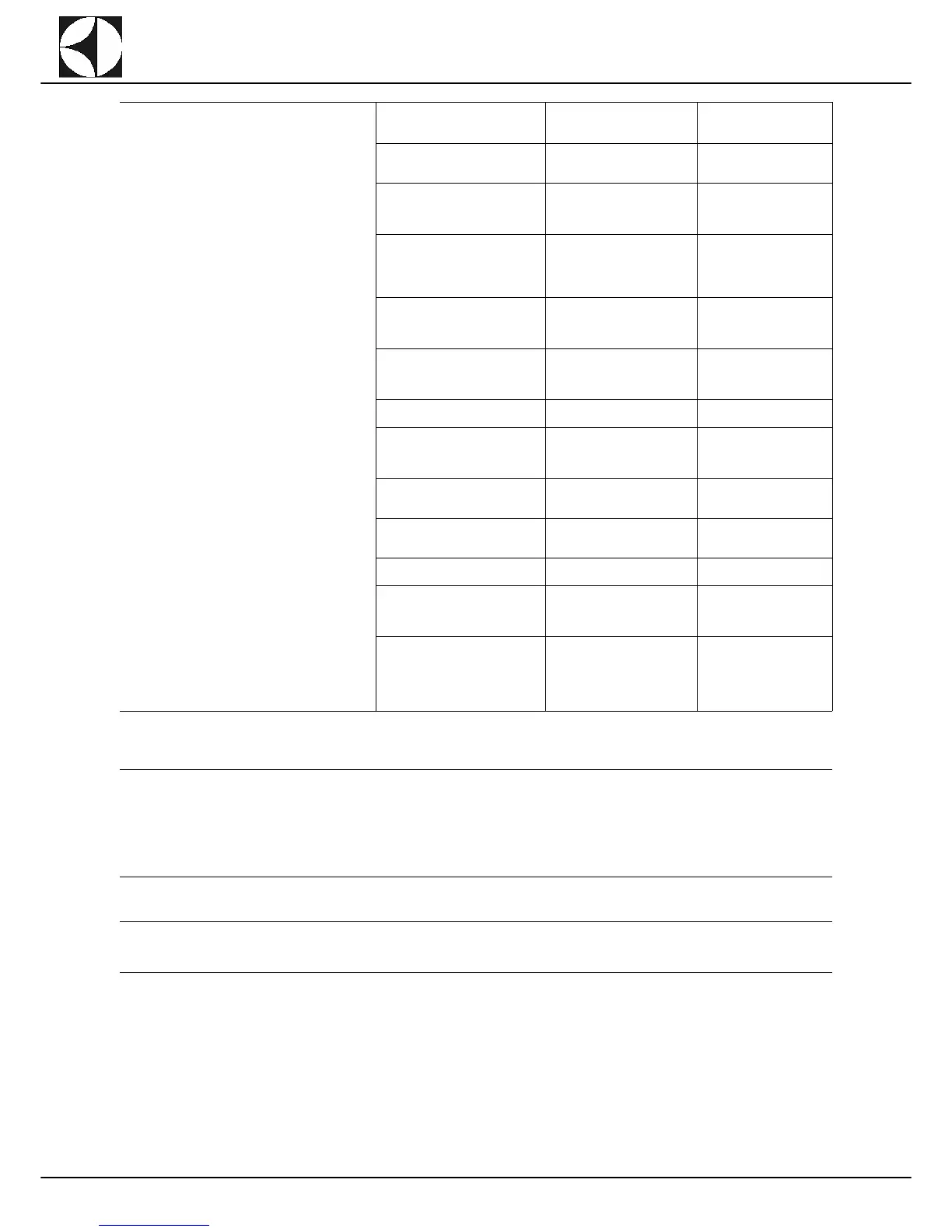

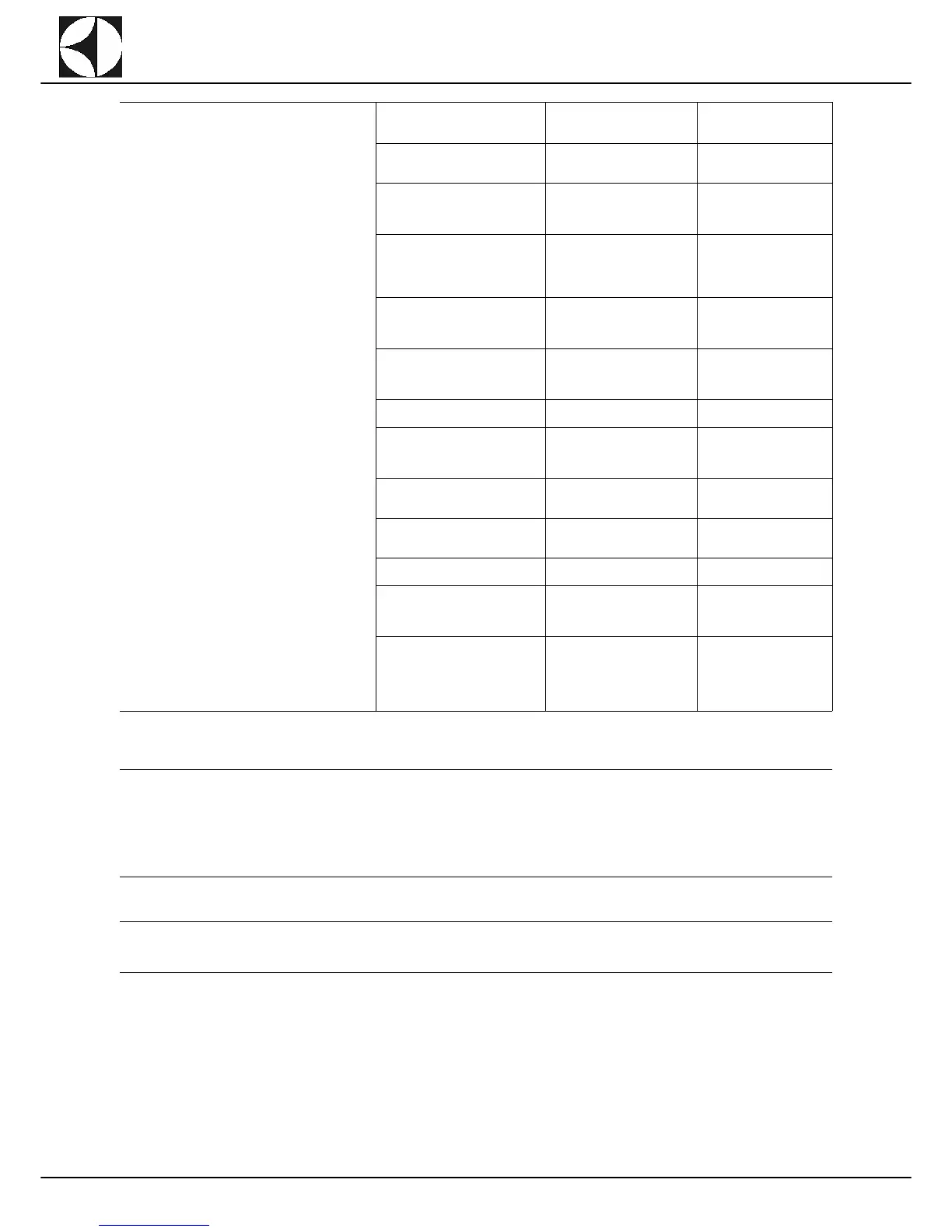

27 The gear motor inverter has

generated an allarm.(compact

machines only).

- The inverter or the gear motor

doesn’t work properly. Possible

machine alarms documented on

Possible cause Remedy

1) overcurrent - ramp too short

- inertia or load too high

- mechanical locking

- check the state of the

mechanism.

2) motor short circuit - insulation fault or short-

circuit at the drive output

- check the cables

connecting the drive to

the motor , and the motor

insulation.

3) internal fault - internal fault - check the environment

(electromagnetic

compatibility).

- send the drive to be

checked/repaired.

4) configuration fault - The current configuration is

inconsistent

- some parameters in the

inverter have been modified

- return to factory settings.

5) overspeed - instability or

- driving load too high

- some parameters in the

inverter have been modified

- return to factory settings.

6) internal fault - load relay control fault or

damaged load resistor

- replace the drive.

7) drive overload - drive temperature too high - check the motor load

and the enviroment.Wait

for the drive to cool down

before restarting.

8) motor overload - triggered by motor current

too high

- check the motor load.

Wait for the drive to cool

down before restarting.

9) overvoltage - line voltage too high

- disturbed line supply

- check the line voltage.

The overvoltage thresold

is 415 V on the DC bus.

10) overvoltage during

deceleration

- braking too sudden or

driving load.

- increase the

deceleration time.

11) line phase failure - drive incorrectly supplied or

a fuse blown

- failure of one phase

- unbalanced load

- check the power

connection and the fuses.

- reset.

12) undervoltage - line supply too low

- transient voltage dip

- damaged load resistor

- check the voltage and

the voltage parameter.

The undervoltage

threshold is 230 V on the

DC bus.

- replace the drive.

30

**

The Air gap was not completely

emptied within the max. emptying

time.

- The impeller rotation is wrong.

- The non return valve on the air gap doesn’t work properly.

- The pressure sensor on the air gap doesn’t work properly.

- The air gap air trap is not clean.

31 The wash tank was not completely

filled within the max. filling time.

- The wash tank water supply cock is not open.

- The water load solenoid valve doesn’t work properly.

- The water feed flow is too low.

- The water inlet filter is not clean.

- The pressure sensor on the wash tank doesn’t work properly.

- The wash tank overflow has not been inserted.

- The wash tank drain solenoid valve doesn’t work properly and remains open.

- The pressure sensor on the wash board doesn’t work properly.

- The wash board doesn’t work properly.

32 The pressure sensor on the wash

tank does not work correctly.

- The pressure sensor on the wash board doesn’t work properly.

- The wash board doesn’t work properly.

33

**

The required temperature in the

wash tank was not reached within

the max. heating time.

- A heating element or a heating element branch of the wash board doesn’t work properly.

- The wash tank temperature sensor doesn’t work properly.

- The wash tank heating element starter controller doesn’t work properly or its coil is not correctly

connected to the rinse board.

Loading...

Loading...