13.5 Other troubleshooting

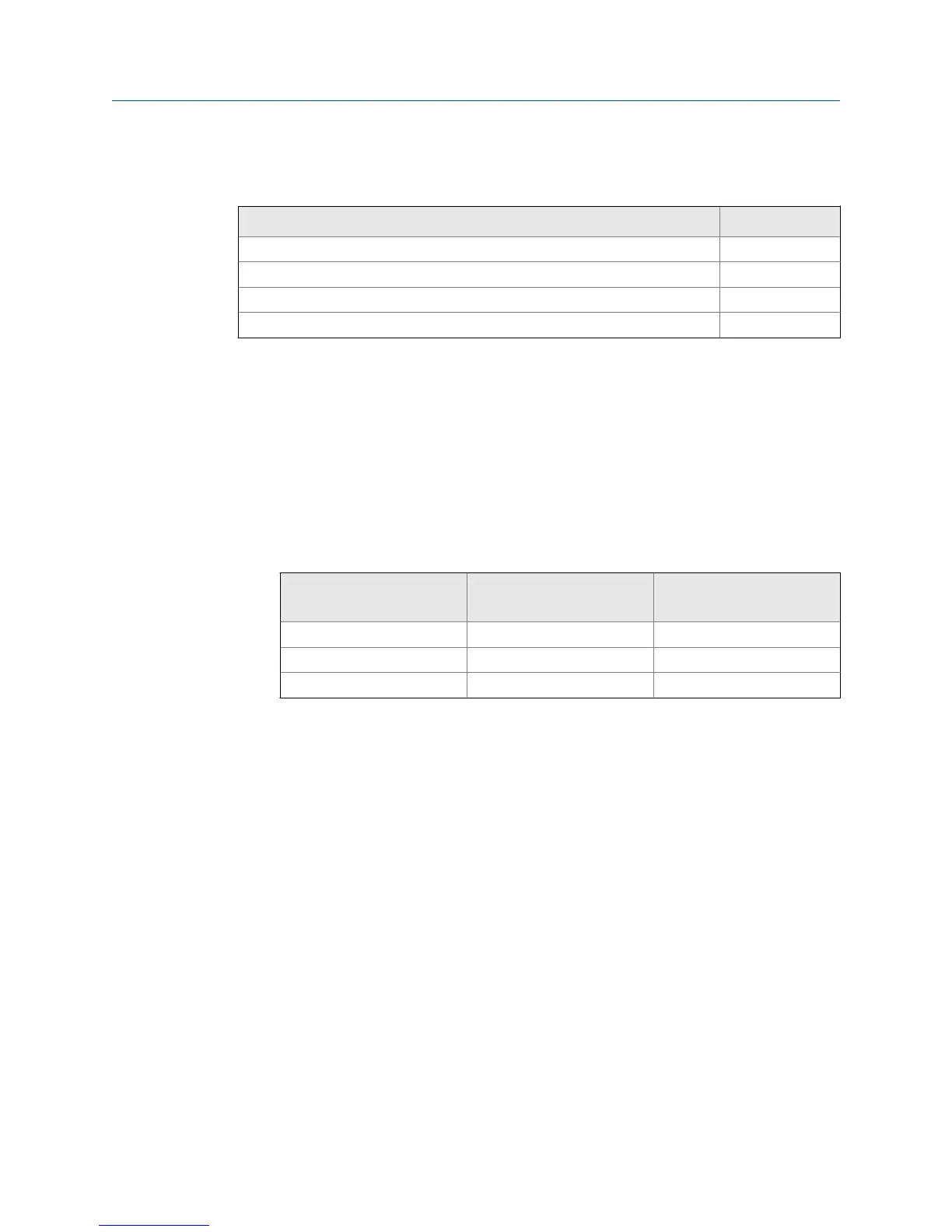

Problem See Section

Readings are too low. Section 13.5.1

Process readings are erratic or wander. Section 13.5.2

Readings drift. Section 13.5.3

Readings are too high. Section 13.5.4

13.5.1 Readings are low.

1. Does the reagent carboy contain reagent? Is the reagent uptake tubing below the

level of the reagent? Has potassium iodide been added to the acetic acid (vinegar)

reagent?

2. Is there adequate flow to the overflow sampler? Excess sample should be flowing

down the inside tube of the overflow sampler.

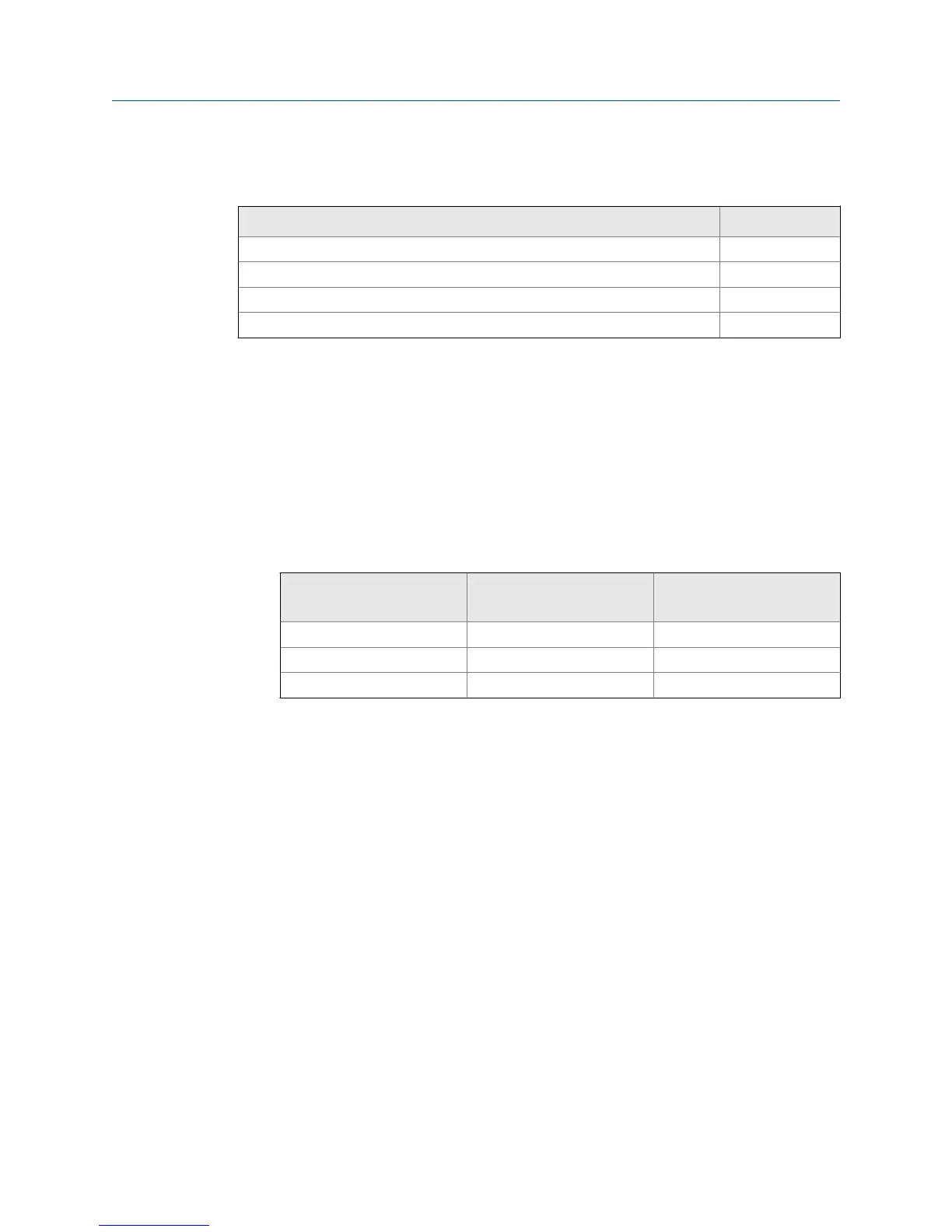

3. Does the reagent contain the correct amount of potassium iodide? See the table.

Expected range, ppm as Cl

2

Amount of KI needed per 5

gallons of vinegar Part number

0 - 5 ppm 25 grams 24164-00

0 - 10 ppm 50 grams 24164-01

0 - 20 ppm 2 x 50 grams 24164-01

4. Was the comparison or calibration sample tested as soon as it was taken? Chlorine

solutions can be unstable. Test the sample immediately after collecting it. Avoid

exposing the sample to sunlight.

5. Is the membrane fouled or coated? A dirty membrane inhibits diffusion of iodine

through the membrane, reducing sensor current. Clean the membrane by rinsing it

with a stream of water from a wash bottle. Wipe gently with a soft tissue.

6. Are the reagent and sample pumps running? If a pump is not running, check the fuse

and replace it if necessary. See Table 12-2 for part numbers. If the fuse is okay,

replace the pump.

7. Are all the tube fittings tight? Pay particular attention to the Luer fittings that

connect the tubing to the pumps.

8. Does the pump tubing element need replacing? Remove the tubing from the pump

and inspect it. If the tubing appears permanently pinched or deformed, replace the

tubing. Refer to Section 12.3.4 for instructions on how to remove and replace the

tubing elements. The expected life of a tubing element is about one year.

Troubleshooting

Manual 71

Loading...

Loading...