14

4.6. Connection Test

After nishing device connections, you can check the connection that you’ve done by using the

automatic test function.

When you press the BACK button for 3 seconds, it switches to test mode. The following conditions

must be applied for proper operating test mode:

• At least 20% of nominal voltage must be applied to the voltage measurement inputs.

• At least 10% of the nominal current must be applied to the current measurement inputs.

• The angle dierence between current and voltage inputs must be less than 30 degrees

(cosφ value should be between inductive 0,87 and capacitive 0,87.)

During connection test, the device controls the connections and it can correct them internally or it can

leave the physical correction to the user.

If there’s an error between voltage inputs, it can only be corrected by changing physical connections.

If you encounter Error 12, make sure that all connections are done and make sure that the test con-

ditions stated above are applied.

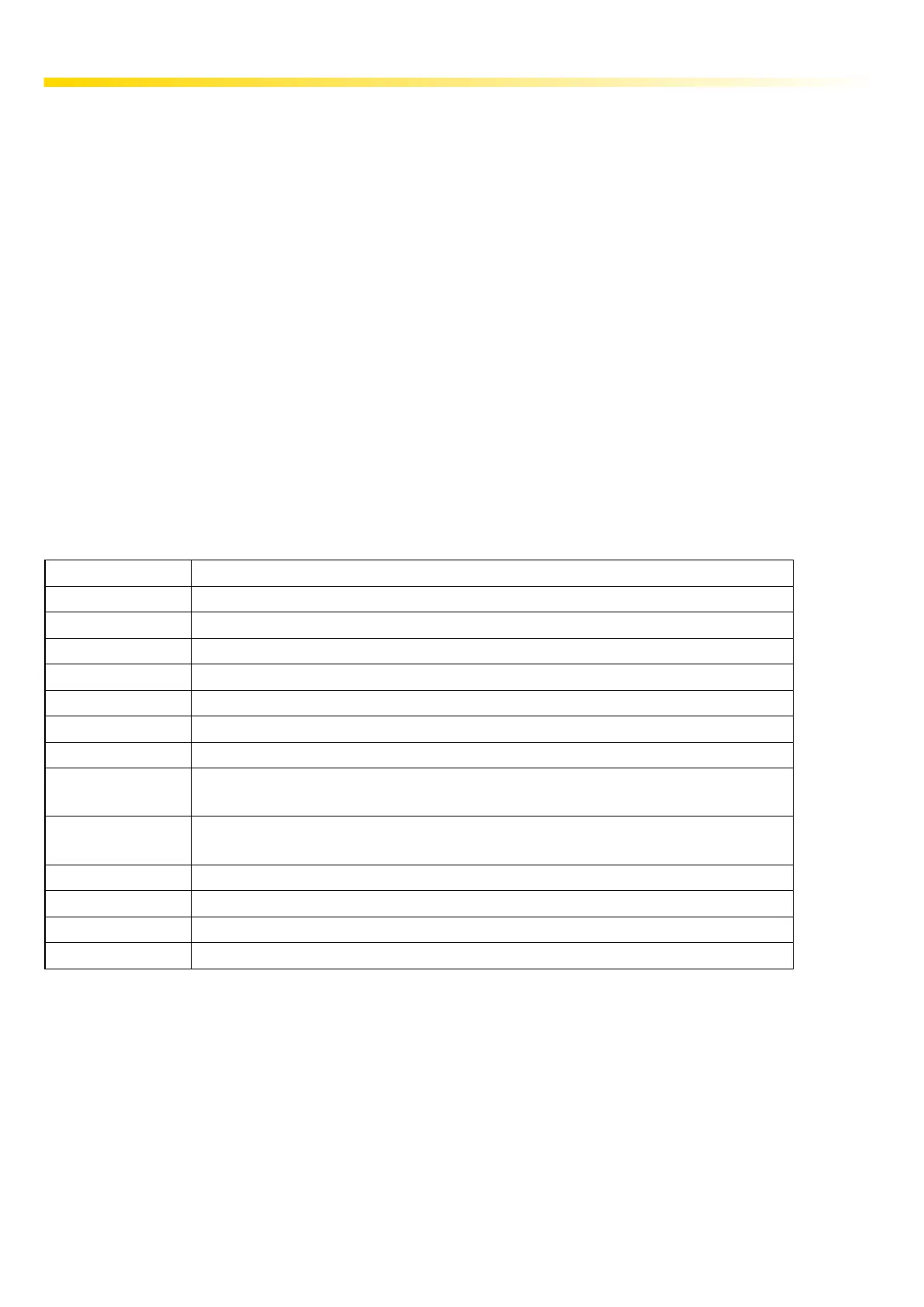

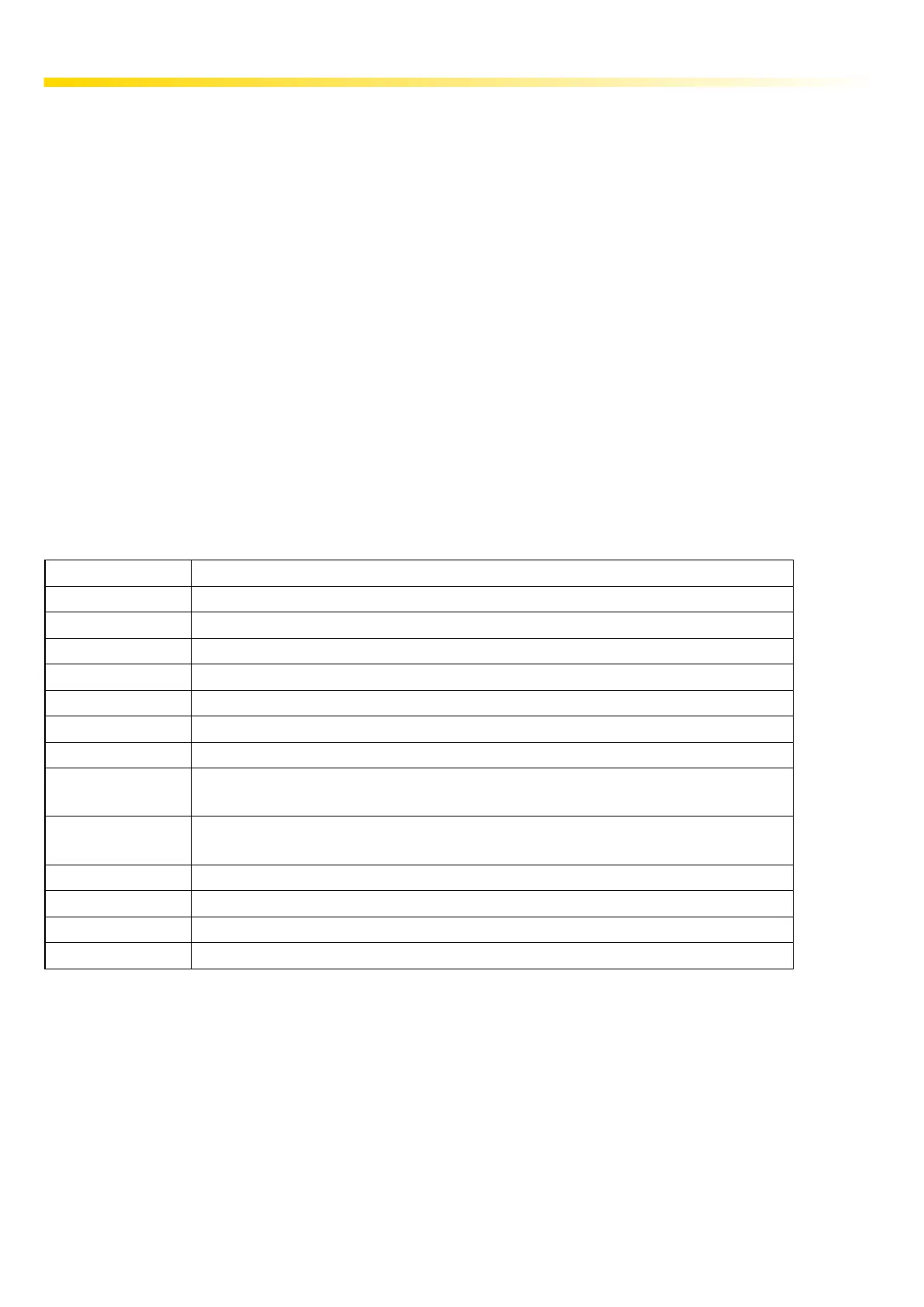

At the following table, possible connection errors that may be encountered during connection test and

their corresponding error codes that are displayed on the device screen.

Test Error Code Test Code Description

0 All connections are correct

1 Phase-1 current direction is reversed

2 Phase-2 current direction is reversed

3 Phase-3 current direction is reversed

4 Phase-1 and Phase-2 voltage connections are reversed

5 Phase-1 and Phase-3 voltage connections are reversed

6 Phase-2 and Phase-3 voltage connections are reversed

7 Voltage connection phase sequence will be changed L1, L2, L3 to

L3, L1, L2

8 Voltage connection phase sequence will be changed L3, L2, L1 to L3,

L1, L2

9 CT-1, CT-2 will be swapped.

10 CT-1, CT-3 will be swapped.

11 CT-2, CT-3 will be swapped.

12 Test conditions are not met.

Loading...

Loading...