EPSON Stylus CX7300/CX7400/DX7400/NX200/TX200 series/SX200 series/Stylus CX8300/CX8400/DX8400/NX400/TX400 series/SX400 series Revision C

OPERATING PRINCIPLES Overview 46

Confidential

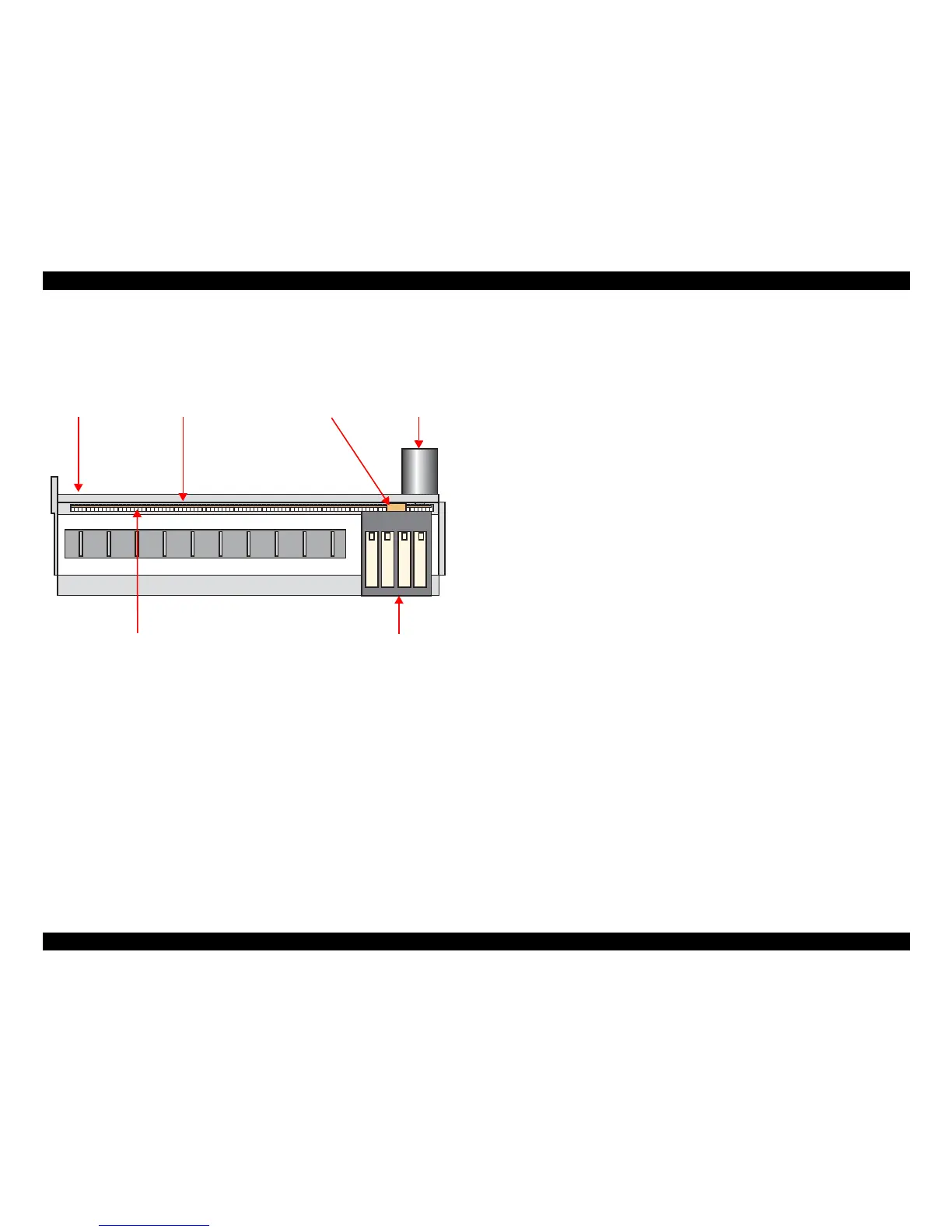

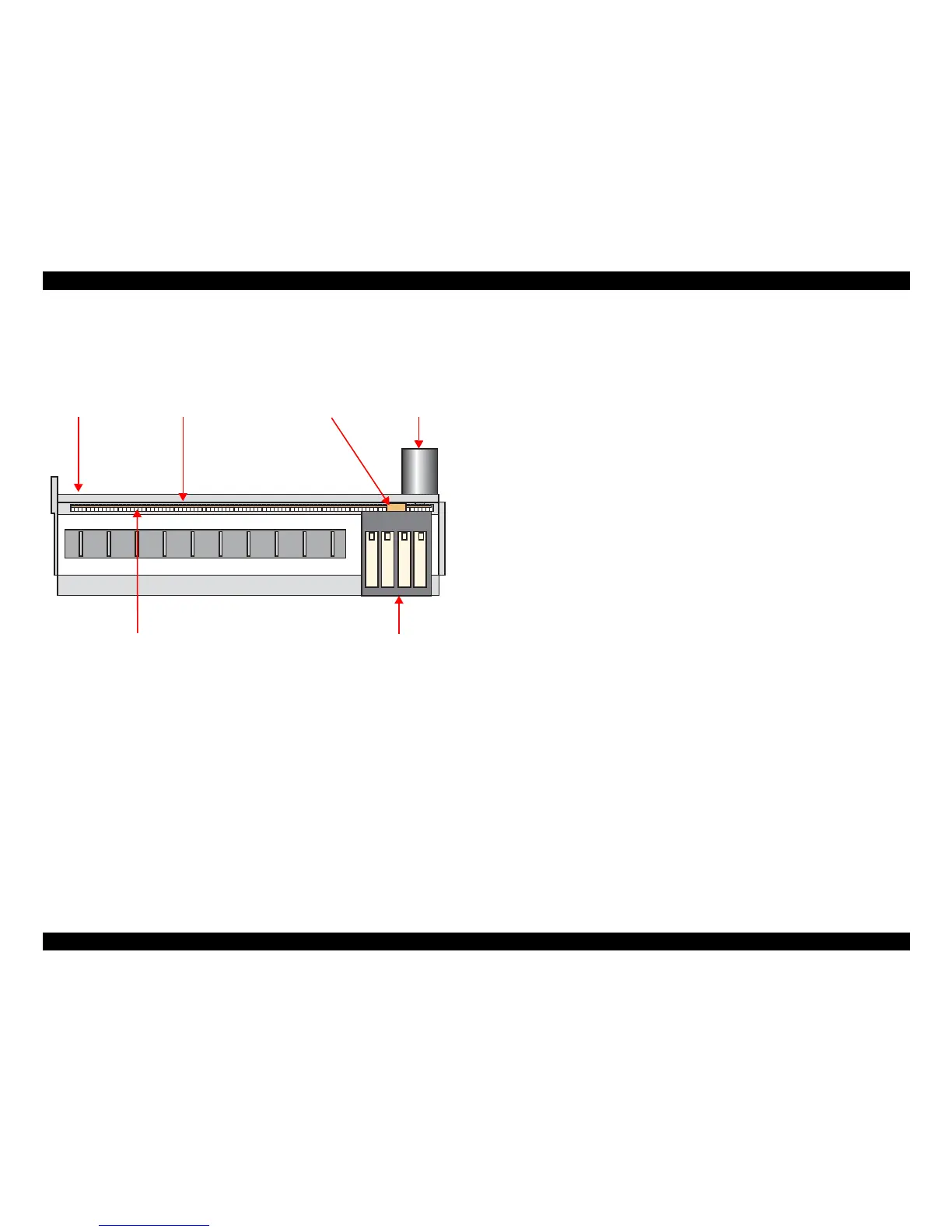

2.1.4 Carriage Mechanism

The carriage mechanism components include the carriage unit (including printhead,

CR encoder sensor), CR motor, timing belt, and CR scale.

The operating principles of the carriage mechanism are described below.

Figure 2-7. Carriage Mechanism

2.1.4.1 CR Motor Control

This printer employs closed-loop control, via the CR motor and an encoder, to control

the carriage speed and position. Since the CR motor is DC motor, the printer controls

the motor in the following methods in order to ensure stable print quality.

Heat control

The heat control over the CR motor is carried out based on the electrical

characteristic of the motor such as torque constants, coil resistance and power

supply voltages.

CR motor drive dispersion measurement sequence

Variations in torque constant, coil resistance and power supply voltage of the

motor are measured in a CR motor drive dispersion measurement sequence when

the CR mechanical load is in the initial state and saved into the EEPROM.

According to the variations measured in the sequence, the voltage is corrected to

make the drive current value constant reducing an individual difference.

CR measurement sequence

To set the appropriate drive voltage for the CR motor in accordance with variation

of the CR motor mechanical load, the printer runs a CR measurement sequence

and stores the measured data into the EEPROM at power-on or in an ink cartridge

replacement sequence. A fatal error occurs if the printer detects that too much load

is applied to the CR motor.

The above control and sequences enable to correct the drive voltage for the CR motor

based on the mechanical load and the electrical characteristic of the motor. According

to the corrected drive voltage, heating value of the motor is calculated. The printer

automatically provides wait time per CR path during printing when the predetermined

heating value is reached.

2.1.4.2 Carriage Home Position Detection

Like the previous model, the carriage home position is detected by the CR motor drive

electric current and carriage speed/position signals sent from the CR encoder. The

detection sequence performed at power-on is described below.

1. Drives the CR motor to move the carriage until it contacts with the right

frame, and then stops the CR motor. The carriage position is set as a position

specified number of counts rightward from the home position.

2. Moves the carriage again to the carriage lock position to check the lock for

proper operation.

3. The printer starts to monitor the carriage position through the CR encoder.

The printer causes a fatal error if too much load on the CR motor is detected due to

obstruction on the carriage path or if no carriage position information is obtained due to

CR encoder or CR scale failure.

Loading...

Loading...