ESAB FABRICATOR 141i

Manual 0-5420 3-5 INSTALLATION, OPERATION AND SETUP

!

WARNING

DO NOT tamper with the relief valve or

remove it from the flowmeter/ regulator.

!

WARNING

Stand to the side of the cylinder opposite

the flowmeter/ regulator when open-

ing the cylinder valve. Keep the cylinder

valve between you and the flowmeter/

regulator. For your safety, NEVER STAND

IN FRONT OF OR BEHIND A FLOWMETER/

REGULATOR WHEN OPENING THE CYLIN-

DER VALVE!

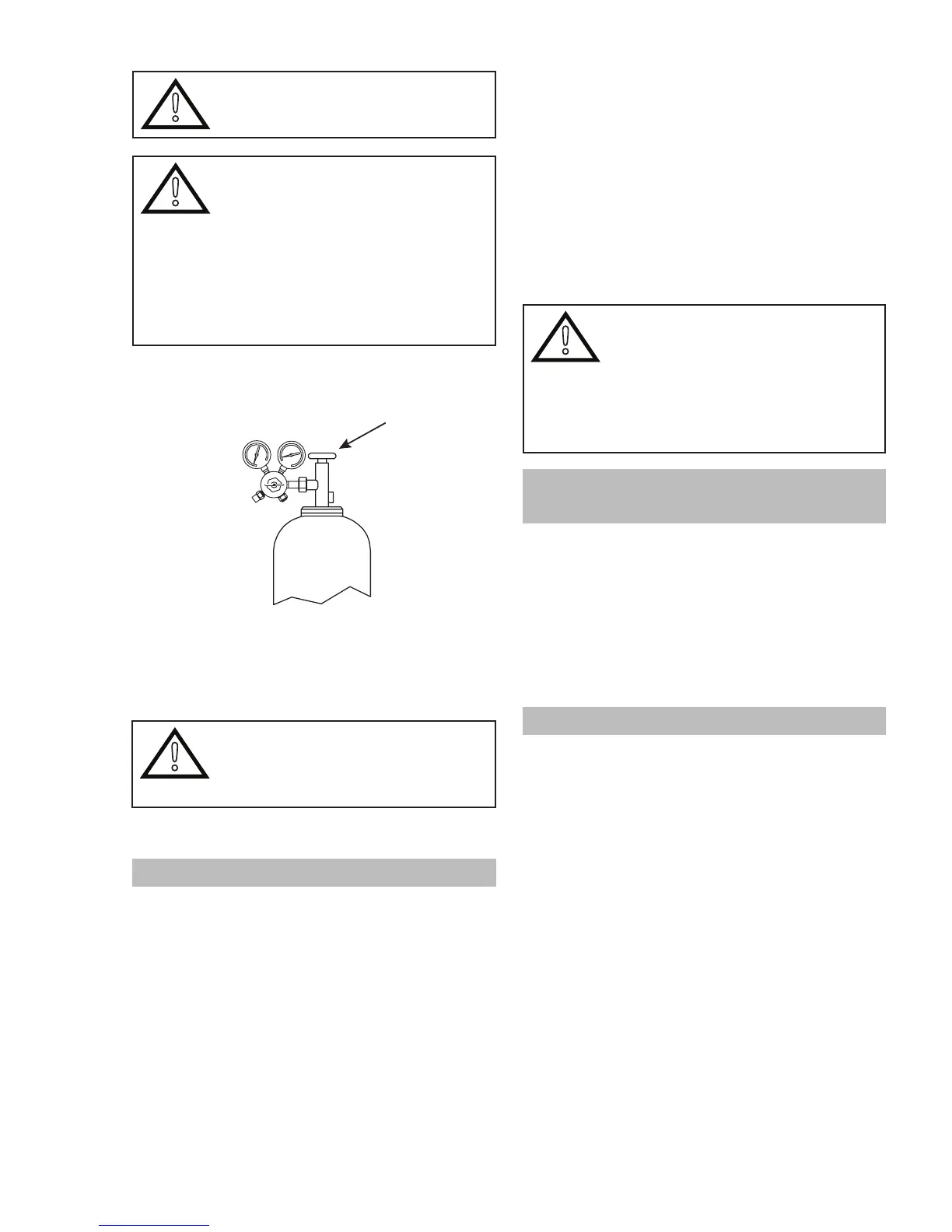

8. Slowly and carefully open the cylinder valve (Figure

3-3) until the maximum pressure shows on the high

pressure gauge.

Figure 3-3: Open Cylinder Valve

9. On all cylinders, open the valve completely to seal the

valve packing. On gaugeless flowmeters/ regulators,

the indicator will register the cylinder contents open.

!

CAUTION

Keep the cylinder valve wrench, if one is

required, on the cylinder valve to turn OFF

the cylinder quickly, if necessary.

10. Attach the desired downstream equipment.

3.07 Leak Testing the System

Leak test the system before putting into operation.

1. Be sure that there is a valve in the downstream equip-

ment to turn off the gas flow.

2. With the cylinder valve open, adjust the Flowmeter/

regulator to deliver the maximum required delivery

pressure.

3. Close the cylinder valve.

4. Turn the adjusting screw/knob counterclockwise one

turn.

a) If the high-pressure gauge reading drops, there is

a leak in the cylinder valve, inlet fitting, or high-

pressure gauge.

b) If the low-pressure gauge drops, there is a leak

in the down stream equipment, hose, hose fitting,

outlet fitting or low-pressure gauge. Check for

leaks using an approved leak detector solution.

c) If the high-pressure gauge drops and the low-

pressure gauge increases at the same time, there

is a leak in the flowmeter/ regulator seat.

d) If the flowmeter/ regulator requires service or

repair, take it to a qualified repair technician.

5. Once leak testing has been performed and there are

no leaks in the system, slowly open the cylinder valve

and proceed.

!

WARNING

If a leak has been detected anywhere in

the system, dis continue use and have

the system repaired. DO NOT use leaking

equipment. Do not attempt to repair a

leaking system while the system is under

pressure.

3.08 When You Finish Using the

Flowmeter/ Regulator

1. Close the cylinder valve.

2. Open the valve on the downstream equipment. This

drains all pressure from the system.

3. Close the valve on the downstream equipment.

4. Turn the adjusting screw counterclockwise to release

the ten sion on the adjusting spring.

5. Check the gauges after a few minutes for verification

that the cylinder valve is closed completely.

3.09

Storage of the Flowmeter/ Regulator

When the regulator is not in use and has been removed from

the cylinder, it should be stored in an area where it will be pro-

tected from dust, oil, and grease. The inlet and outlet should be

capped to protect against internal contamination and prevent

insects from nesting.

Loading...

Loading...