ESAB FABRICATOR 141i

Manual 0-5420 4-11 BASIC WELDING GUIDE

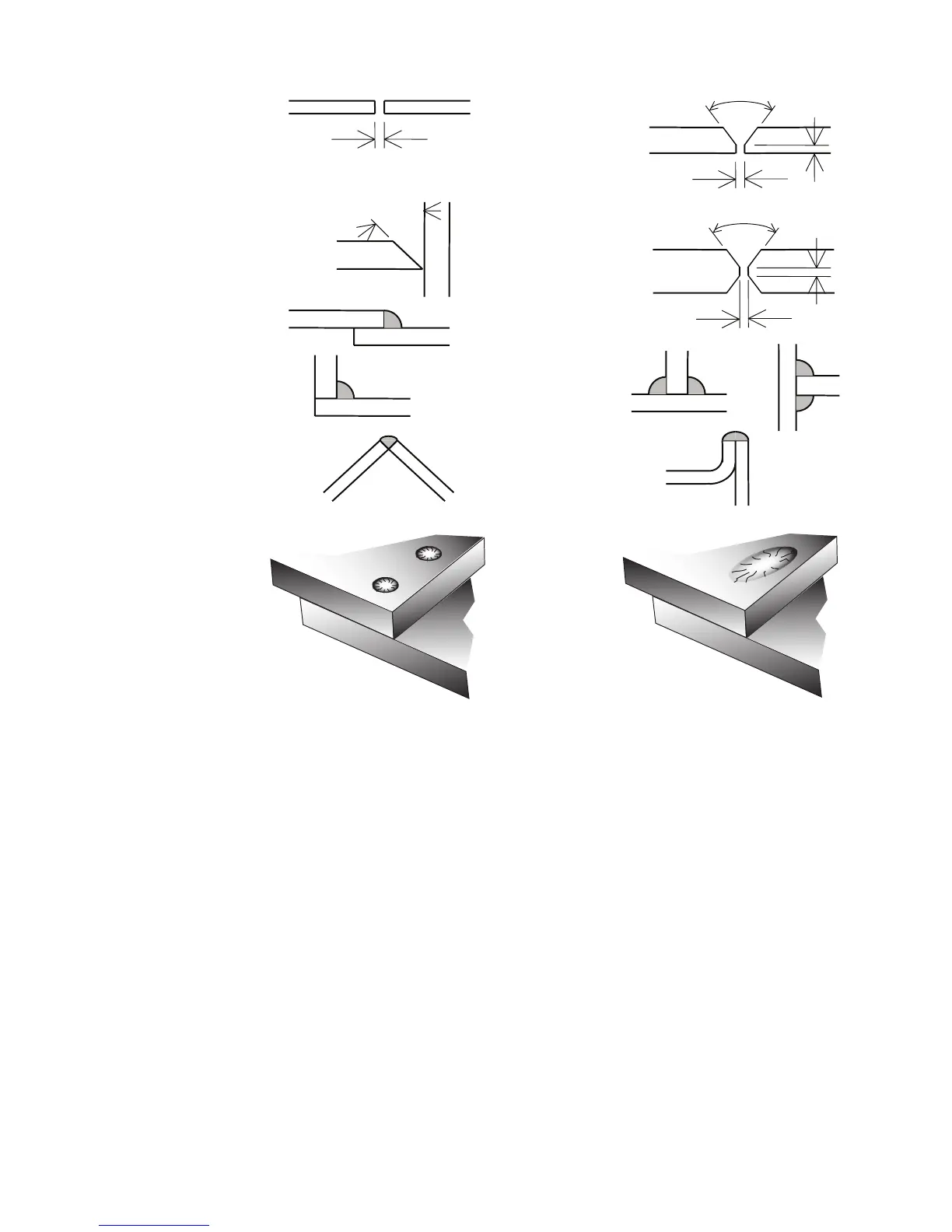

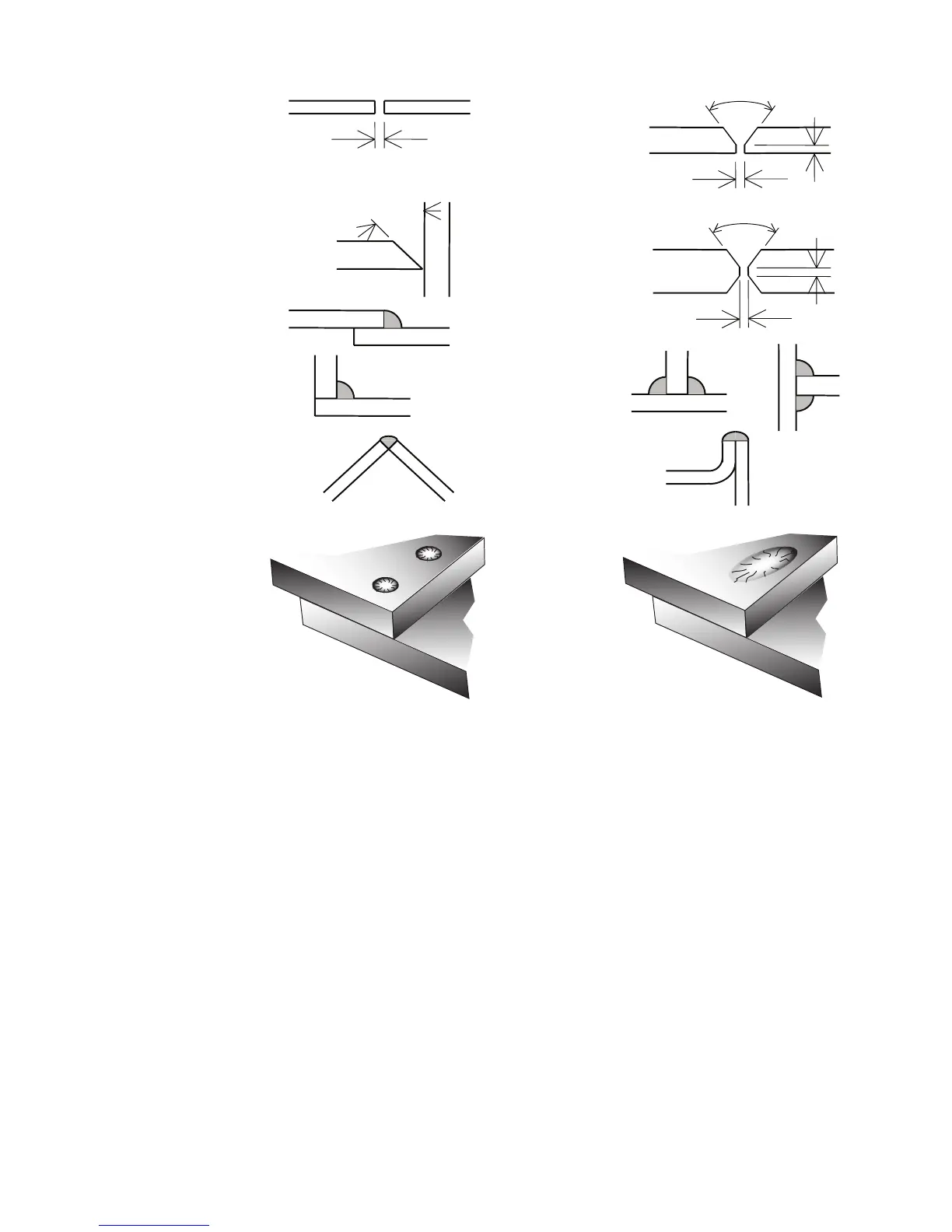

Gap varies from

1/16" (1.6mm) to 3/16" (4.8mm)

depending on plate thickness

Joint

1/16" (1.6mm) max

1.6mm (1/16”)

Single Vee Butt Joint

Not less than

70°

Double Vee Butt Joint

1/16" (1.6mm)

Lap Joint

Tee Joints

(Fillet both sides of the

joint)

Edge Joint

Fillet Joint

Corner Weld

Plug Weld Plug Weld

Not less than

70°

Single Vee Butt Joint

Not less than

45°

1/16" (1.6mm) max

Art # A-10367

Figure 4-19: Typical Joint Designs for Arc Welding

Arc Welding Technique - A Word to Beginners

For those who have not yet done any welding, the simplest way to commence is to run beads on a piece of scrap plate. Use mild

steel plate about 1/4" (6.4mm) thick and a 1/8"(3.2mm) electrode. Clean any paint, loose scale or grease off the plate and set it

firmly on the work bench so that welding can be carried out in the downhand position. Make sure that the work clamp is making

good electrical contact with the work, either directly or through the work table. For light gauge material, always clamp the work

lead directly to the job, otherwise a poor circuit will probably result.

Striking the Arc

Practice this on a piece of scrap plate before going on to more exacting work. You may at first experience difficulty due to the tip of

the electrode "sticking" to the work piece. This is caused by making too heavy a contact with the work and failing to withdraw the

electrode quickly enough. A low amperage will accentuate it. This freezing-on of the tip may be overcome by scratching the elec-

trode along the plate surface in the same way as a match is struck. As soon as the arc is established, maintain a 1/16"(1.6mm) to

1/8"(3.2mm) gap between the burning electrode end and the parent metal. Draw the electrode slowly along as it melts down.

Another difficulty you may meet is the tendency, after the arc is struck, to withdraw the electrode so far that the arc is broken

again. A little practice will soon remedy both of these faults.

Loading...

Loading...