ESAB FABRICATOR 141i

INSTALLATION, OPERATION AND SETUP 3-12 Manual 0-5420

WARNING

Before connecting the work clamp to the work piece, make sure you have ceased feeding wire so prema-

ture arcing will not occur.

The electrode wire will be at welding voltage potential while it is being fed through the system.

Keep MIG Gun away from eyes and face.

Art #

A-10359_AB

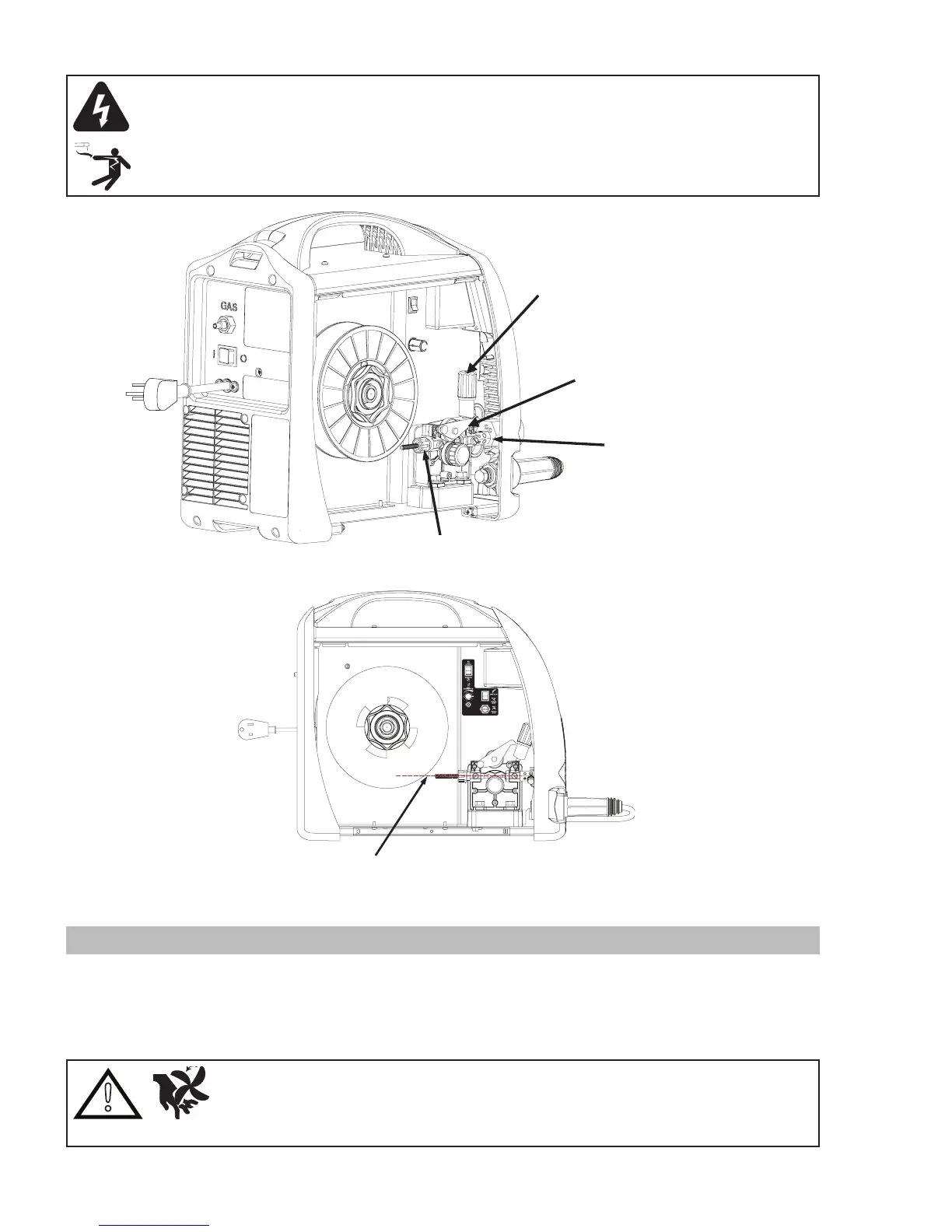

Outlet Guide

Inlet Guide

Wire Drive Tension Screw

Pressure Roller Arm

Figure 3-9: Wire Drive Assembly Components

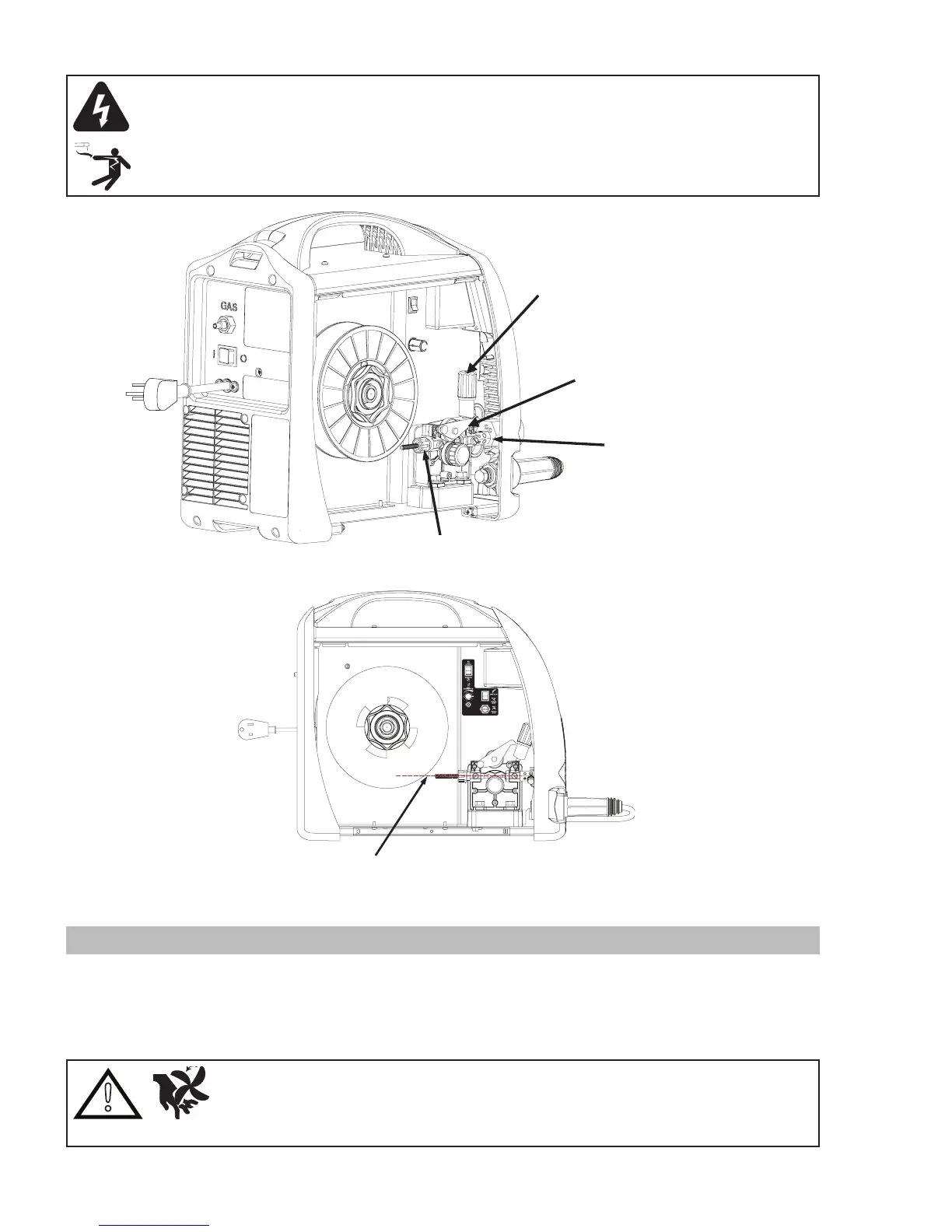

MIG Welding Wire

Art #

A-10360

Figure 3-10: MIG Welding Wire - Installation

3.13 Installing 4" (100mm) Diameter Spool

As delivered from the factory, the Power Source is fitted with a Wire Spool Hub which accepts a 8" (200mm) diameter spools. In

order to fit a 4" (100mm) diameter spool assemble parts in the sequence shown below in Figure 3-11.

Adjustment of the nut with nylon insert will control the MIG Wire Spool Brake. Clockwise rotation of this nut with nylon insert

tightens the brake. The brake is correctly adjusted when the spool stops within 4" (100mm) to 8" (200mm) (measured at the outer

edge of the spool) after MIG Gun trigger is released. Wire should be slack without becoming dislodged from the spool.

!

CAUTION

Overtension of brake will cause rapid wear of mechanical WIRE FEED parts, overheating of

electrical components and possibly an increased incidence of electrode wire Burnback into

contact tip.

Loading...

Loading...