ESAB FABRICATOR 141i

BASIC WELDING GUIDE 4-16 Manual 0-5420

4.05 Stick (SMAW) Welding Troubleshooting

FAULT CAUSE REMEDY

1 Welding current

varying

ARC FORCE control knob

is set at a value that causes

the welding current to vary

excessively with the arc

length.

Reduce the ARC FORCE control knob until welding

current is reasonably constant while prohibiting the

electrode from sticking to the work piece when you

“dig” the electrode into the workpiece.

2 A gap is left by

failure of the weld

metal to fill the

root of the weld.

A Welding current too low A Increase welding current.

B Electrode too large for joint. B Use smaller diameter electrode.

C Insufficient gap. C Allow wider gap.

3 Non-metallic

particles are

trapped in the

weld metal.

A Non-metallic particles may

be trapped in undercut from

previous run.

A If a bad undercut is present clean slag bout and

cover with a run from a smaller gauge electrode.

B Joint preparation too

restricted.

B Allow for adequate penetration and room for

cleaning out the slag.

C Irregular deposits allow slag

to be trapped.

C If very bad, chip or grind out irregularities.

D Lack of penetration with slag

trapped beneath weld bead.

D Use smaller electrode with sufficient current to give

adequate penetration. Use suitable tools to remove

all slag from comers.

E Rust or mill scale is

preventing full fusion.

E Clean joint before welding.

F Wrong electrode for position

in which welding is done.

F Use electrodes designed for position in which

welding is done, otherwise proper control of slag is

difficult.

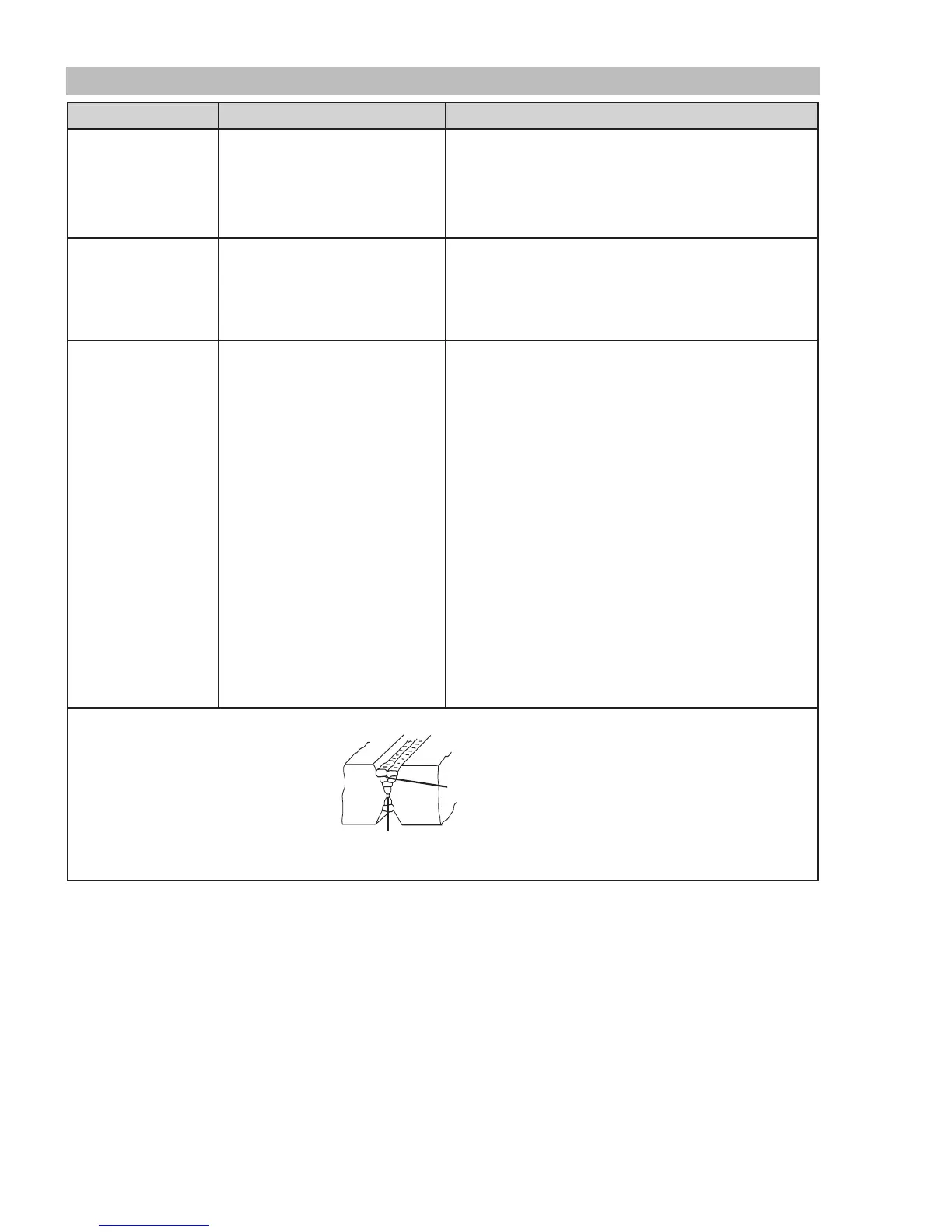

Figure 1- Example of insufficient gap or incorrect sequence

Insufficient Gap

Incorrect Sequence

Art # A-05866_AC

Loading...

Loading...