ESAB FABRICATOR 141i

INSTALLATION, OPERATION AND SETUP 3-14 Manual 0-5420

3.15 Feed Roller Pressure Adjustment

The pressure (top) roller applies pressure to the grooved

feed roller via an adjustable pressure screw. These devices

should be adjusted to a minimum pressure that will provide

satisfactory wire feed without slippage. If slipping occurs, and

inspection of the wire contact tip reveals no wear, distortion or

burn back jam, the conduit liner should be checked for kinks

and clogging by metal flakes and debris. If it is not the cause of

slipping, the feed roll pressure can be increased by rotating the

pressure screw clockwise.

WARNING

Before changing the feed roller ensure

that the Electricity Supply to the Power

Source is switched off.

!

CAUTION

The use of excessive pressure may cause

rapid wear of the feed rollers, shafts and

bearing.

3.16 Changing the Feed Roll

To change feed roll remove the feed roll retaining screw by

turning in an counterclockwise direction. Once the feed roll is

removed then to replace feed roll simply reverse these direc-

tions.

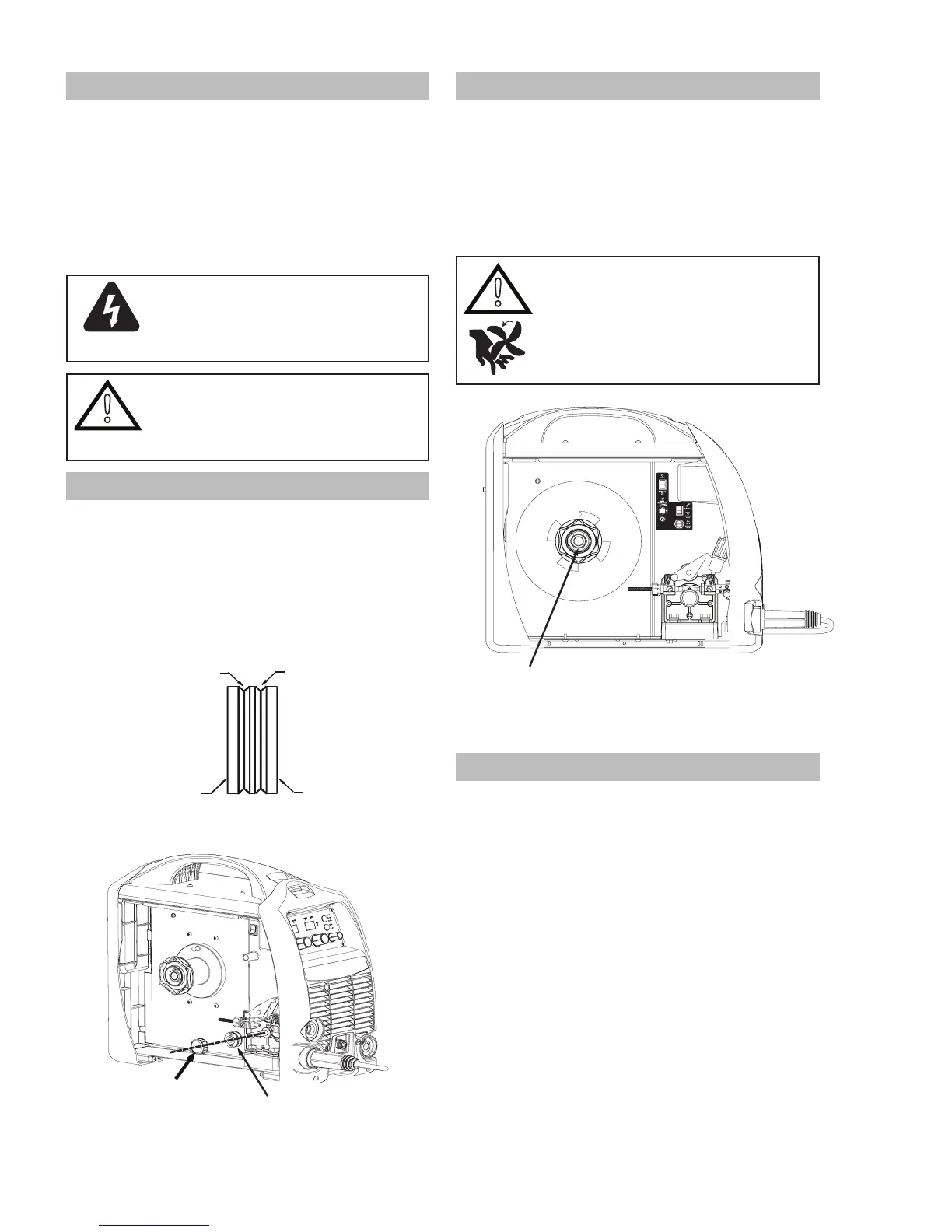

A dual groove feed roller is supplied as standard. It can accom-

modate 023"(0.6mm) -.030" (0.8mm) diameter hard wires.

Select the roller required with the chosen wire size marking

facing outward.

GROOVE “B”GROOVE “A”

GROOVE “A” SIZE

GROOVE “B” SIZE

A-09583

Figure 3-13: Dual Groove Feed Roller

Feed Roll

Retaining Screw

Feed Roll

Art #

A-09584_AC

Figure 3-14: Changing the Feed Roll

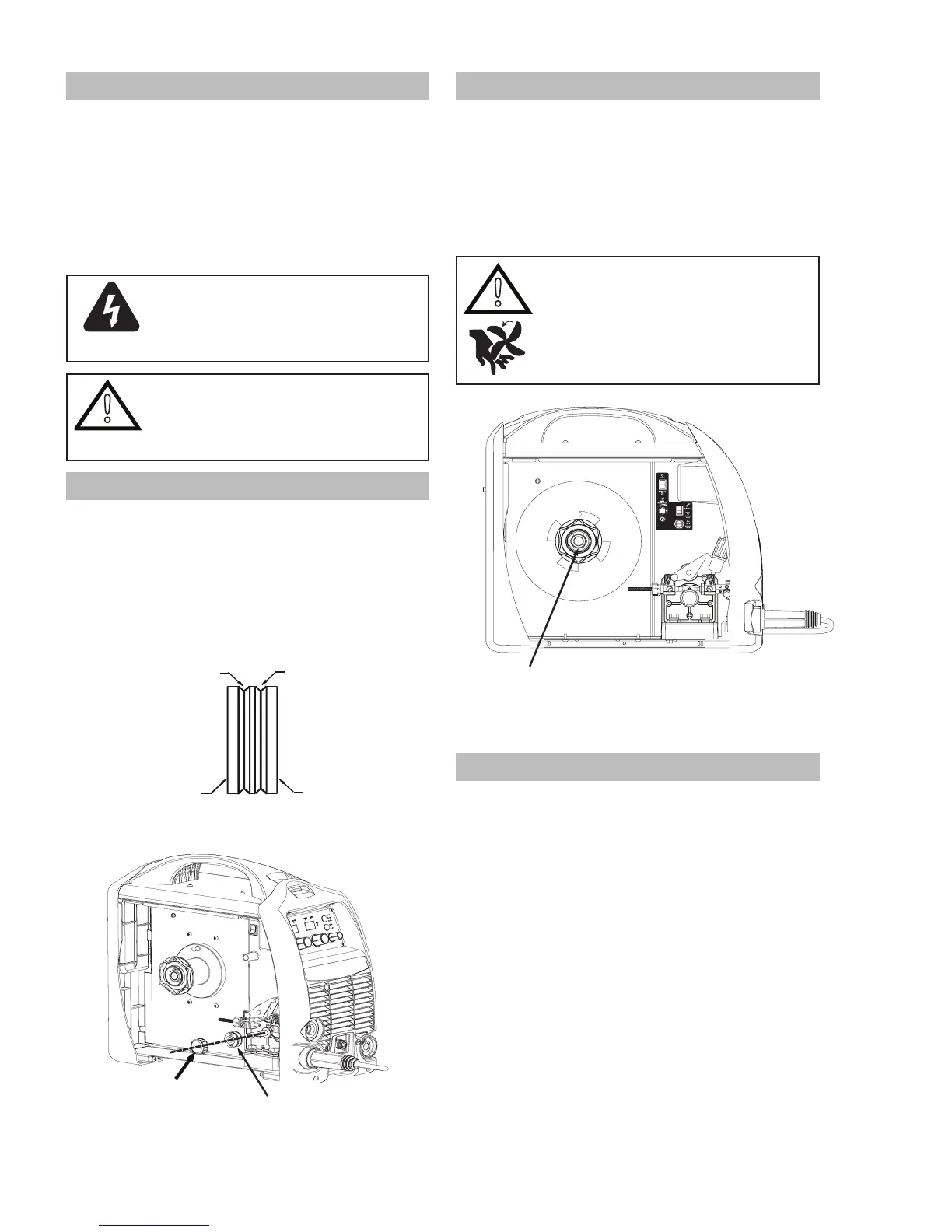

3.17 Wire Reel Brake

The wire reel hub incorporates a friction brake which is

adjusted during manufacture for optimum breaking. If it is

considered necessary, adjustment can be made by turning the

large nut inside the open end of the hub clockwise to tighten

the brake. Correct adjustment will result in the wire reel

circumference continuing no further than 3/8" (10mm) - 3/4"

(20mm) after release of the trigger. The electrode wire should

be slack without becoming dislodged from wire spool.

!

CAUTION

Overtension of brake will cause rapid

wear of mechanical WIREFEED parts,

overheating of electrical components

and possibly an increased incidence of

electrode wire Burnback into contact tip..

Wire Reel Brake Adjustment Nut

Art #

A-10361

Figure 3-15: Wire Reel Brake

3.18 Flowmeter/ Regulator Operation

With the flowmeter/ regulator connected to cylinder or pipeline,

and the adjustment screw/knob fully disengaged, pressurize as

follows:

1. Stand to one side of flowmeter/ regulator and slowly

open the cylinder valve. If opened quickly, a sudden

pressure surge may damage internal parts.

2. With valves on downstream equipment closed, adjust

flowmeter/ regulator to approximate working pres-

sure. It is recommended that testing for leaks at the

flowmeter/ regulator connection points be carried

out using a suitable leak detection solution or soapy

water.

3. Purge air or other unwanted welding grade shield-

ing gas from equipment connected to the flowmeter/

regulator by individually opening then closing the

equipment control valves. Complete purging may take

up to ten seconds or more, depending upon the length

and size of the hose being purged.

Loading...

Loading...