ESAB FABRICATOR 141i

BASIC WELDING GUIDE 4-12 Manual 0-5420

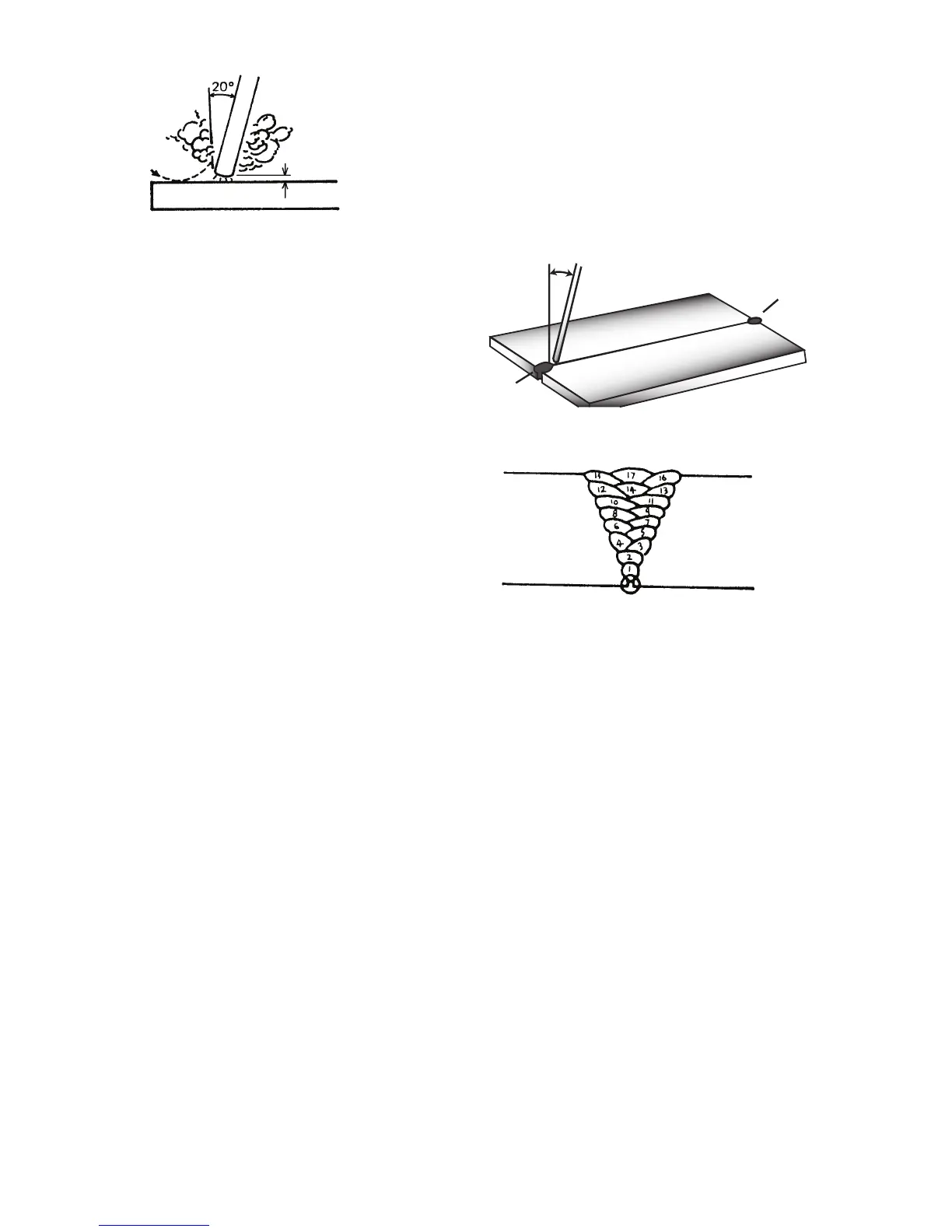

Art # A-10368

1/16" (1.6mm)

Figure 4-20: Striking an Arc

Arc Length

The securing of an arc length necessary to produce a neat

weld soon becomes almost automatic. You will find that a long

arc produces more heat. A very long arc produces a crack-

ling or spluttering noise and the weld metal comes across in

large, irregular blobs. The weld bead is flattened and spatter

increases. A short arc is essential if a high quality weld is to be

obtained although if it is too short there is the danger of it be-

ing blanketed by slag and the electrode tip being solidified in. If

this should happen, give the electrode a quick twist back over

the weld to detach it. Contact or "touch-weld" electrodes such

as E7014 Stick electrodes do not stick in this way, and make

welding much easier.

Rate of Travel

After the arc is struck, your next concern is to maintain it, and

this requires moving the electrode tip towards the molten pool

at the same rate as it is melting away. At the same time, the

electrode has to move along the plate to form a bead. The

electrode is directed at the weld pool at about 20º from the

vertical. The rate of travel has to be adjusted so that a well-

formed bead is produced.

If the travel is too fast, the bead will be narrow and strung

out and may even be broken up into individual globules. If the

travel is too slow, the weld metal piles up and the bead will be

too large.

Making Welded Joints

Having attained some skill in the handling of an electrode, you

will be ready to go on to make up welded joints.

A. Butt Welds

Set up two plates with their edges parallel, as shown in

Figure 4-21, allowing 1/16"(1.6mm) to 3/32"(2.4mm)

gap between them and tack weld at both ends. This is to

prevent contraction stresses from the cooling weld metal

pulling the plates out of alignment. Plates thicker than 1/4"

(6.4mm) should have their mating edges beveled to form a

70º to 90º included angle. This allows full penetration of the

weld metal to the root. Using a 1/8"(3.2mm) E7014 Stick

electrode at 100 amps, deposit a run of weld metal on the

bottom of the joint.

Do not weave the electrode, but maintain a steady rate of

travel along the joint sufficient to produce a well-formed

bead. At first you may notice a tendency for undercut to form,

but keeping the arc length short, the angle of the electrode at

about 20º from vertical, and the rate of travel not too fast, will

help eliminate this. The electrode needs to be moved along

fast enough to prevent the slag pool from getting ahead of

the arc. To complete the joint in thin plate, turn the job over,

clean the slag out of the back and deposit a similar weld.

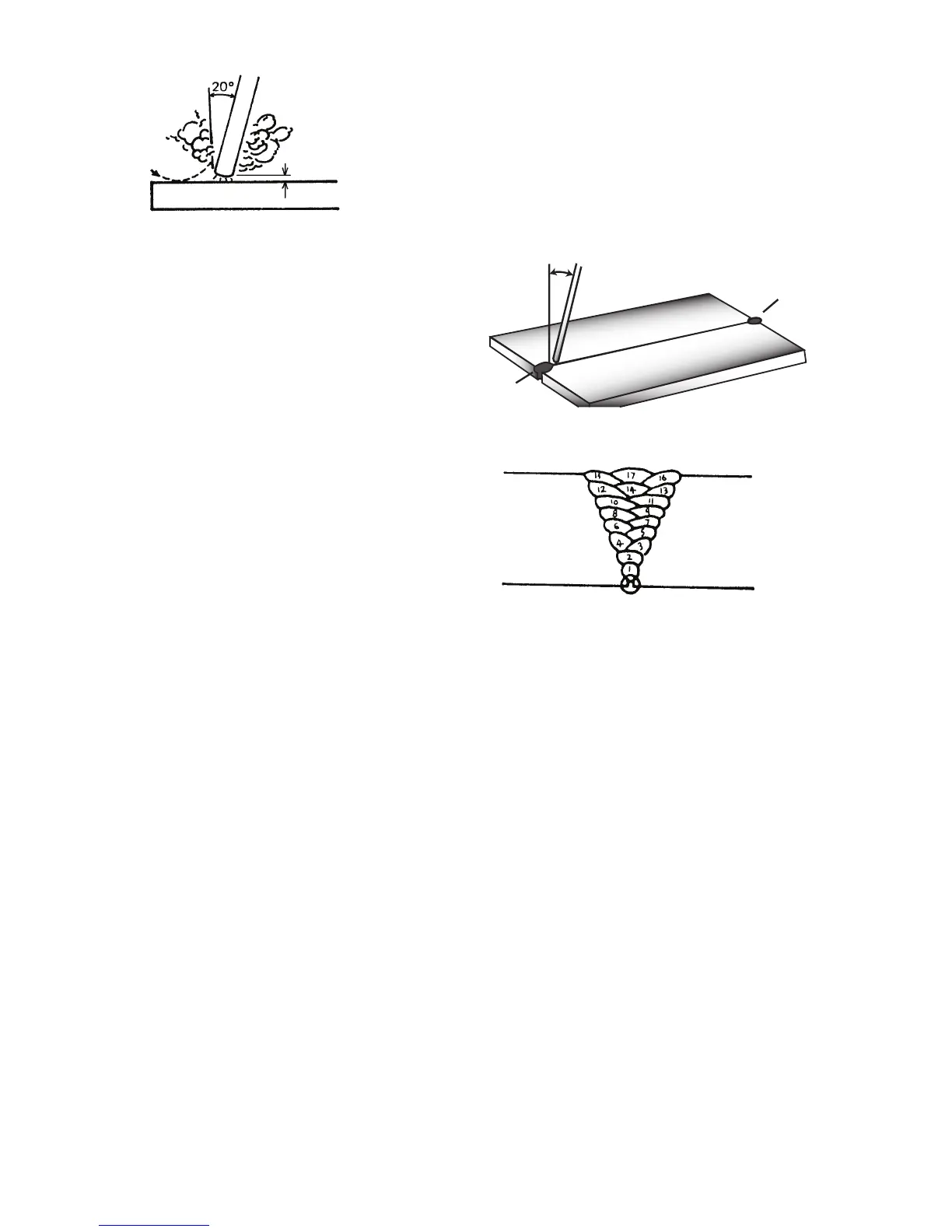

Art # A-07697_AB

Tack Weld

Electrode

Tack Weld

Figure 4-21: Butt Weld

Art # A-07698

Figure 4-22: Weld Build up Sequence

Heavy plate will require several runs to complete the joint.

After completing the first run, chip the slag out and clean the

weld with a wire brush. It is important to do this to prevent

slag being trapped by the second run. Subsequent runs are

then deposited using either a weave technique or single

beads laid down in the sequence shown in Figure 4-22. The

width of weave should not be more than three times the core

wire diameter of the electrode. When the joint is completely

filled, the back is either machined, ground or gouged out

to remove slag which may be trapped in the root, and to

prepare a suitable joint for depositing the backing run. If a

backing bar is used, it is not usually necessary to remove

this, since it serves a similar purpose to the backing run in

securing proper fusion at the root of the weld.

B. Fillet Welds

These are welds of approximately triangular cross-section

made by depositing metal in the corner of two faces meeting

at right angles. Refer to Figure 4-14.

A piece of angle iron is a suitable specimen with which to

begin, or two lengths of strip steel may be tacked together

at right angles. Using a 1/8"(3.2mm) E7014 Stick electrode

at 100 amps, position angle iron with one leg horizontal and

the other vertical. This is known as a horizontal-vertical (HV)

fillet. Strike the arc and immediately bring the electrode to

a position perpendicular to the line of the fillet and about

Loading...

Loading...