155

Torch

body

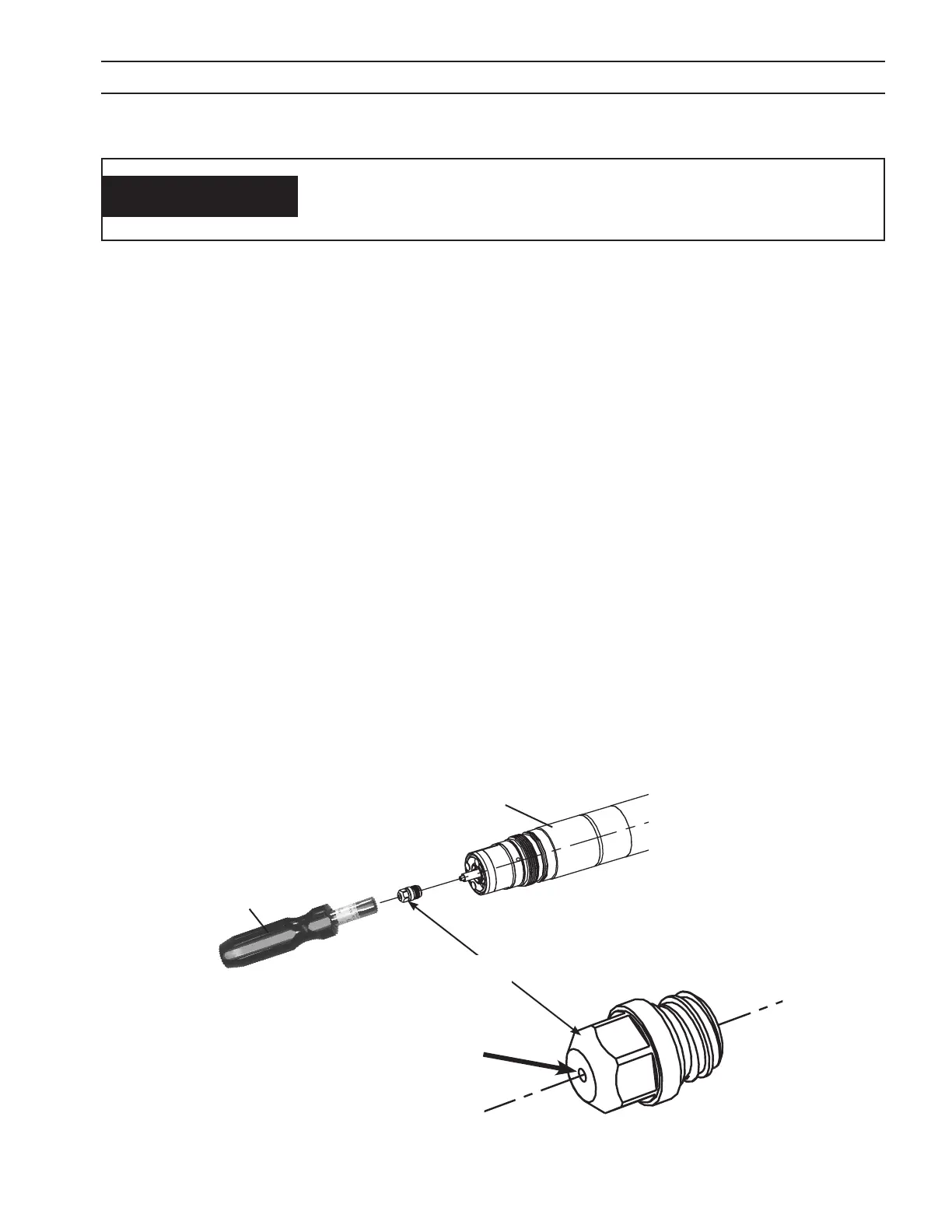

Electrode

Removal

Tool

4. Unscrew nozzle retainer and pull nozzle straight out of torch body. Inspect insulator portion of the nozzle

retainer for cracks or chipping. Replace if damaged.

Inspect nozzle for:

melting or excessive current transfer •

gouges from internal arcing •

nicks or deep scratches on the O-ring seating surfaces •

O-ring cuts, nicks, or wear •

Remove hafnium particles (from the electrode) with steel wool•

Replace if any damage is found.

NOTE:

Discoloration of internal surfaces and small black starting marks are normal and do not eect cutting

peformance.

If the holder was tightened suciently, the electrode may unscrew without being attached to the electrode

holder. When installing the electrode, use only sucient force to adequately secure the electrode.

5. Remove electrode using electrode removal tool.

6. Disassemble electrode from electrode holder. Insert ats on the holder into a 5/16" wrench. Using the elec-

trode tool, rotate electrode counter-clockwise to remove. Replace electrode if center insert is pitted more

than 0.09" (3/32").

CAUTION

Incorrect assembly of the diuser in the shield will prevent the torch

from working properly. Diuser notches must be mounted away

from the shield as illustrated.

SECTION 5 MAINTENANCE

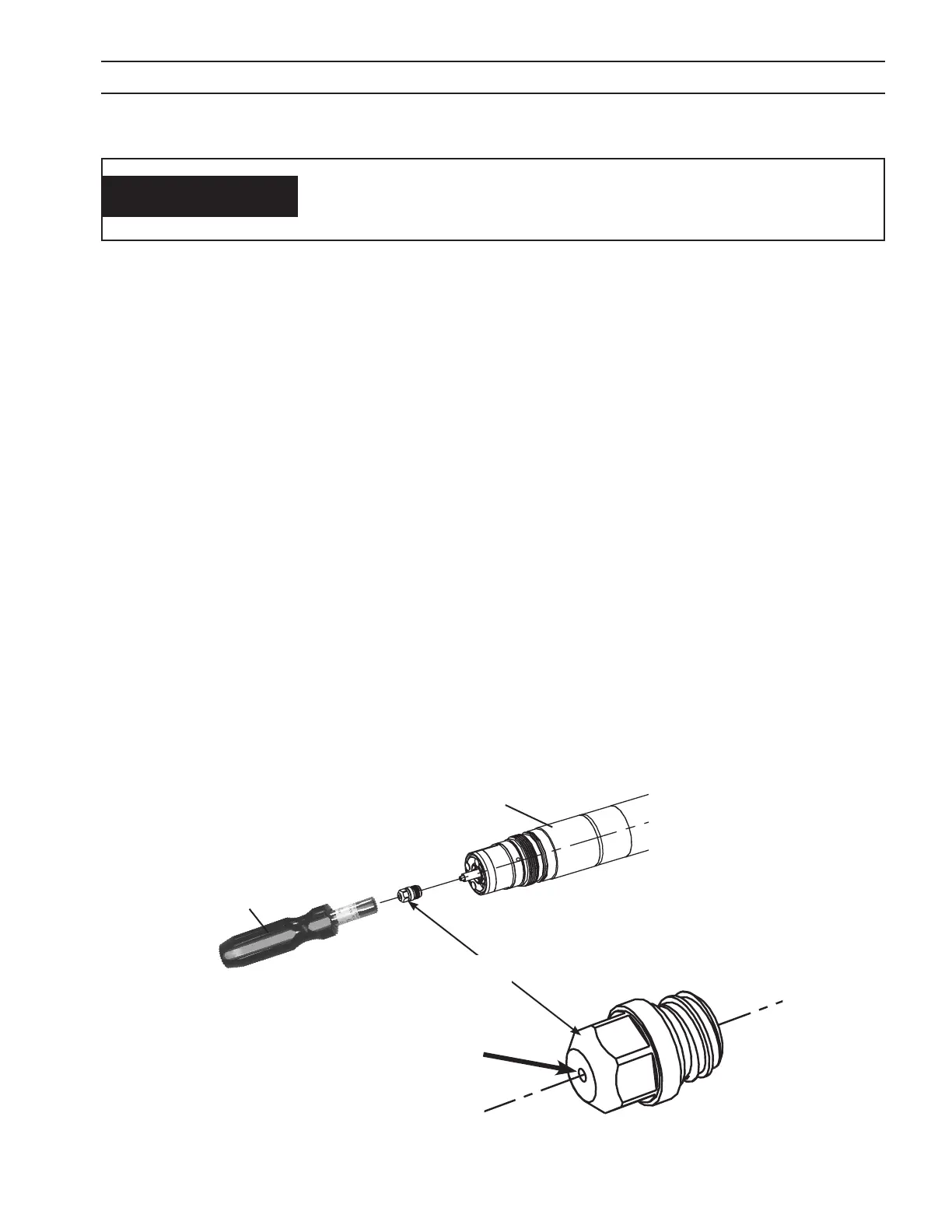

Electrode

Replace electrode if center insert is

pitted more than 0.09" (3/32")

Loading...

Loading...