T-SM5f Page 11 of 29

MR & MRS OPERATION TABLES

Part 4

4. MAINTENANCE

gears on the idler plate (Fig. 6) still have clearance

and that securing screws are tight on driving and

idler gears in main gear train. Check grub screw

securing pivot bolt.

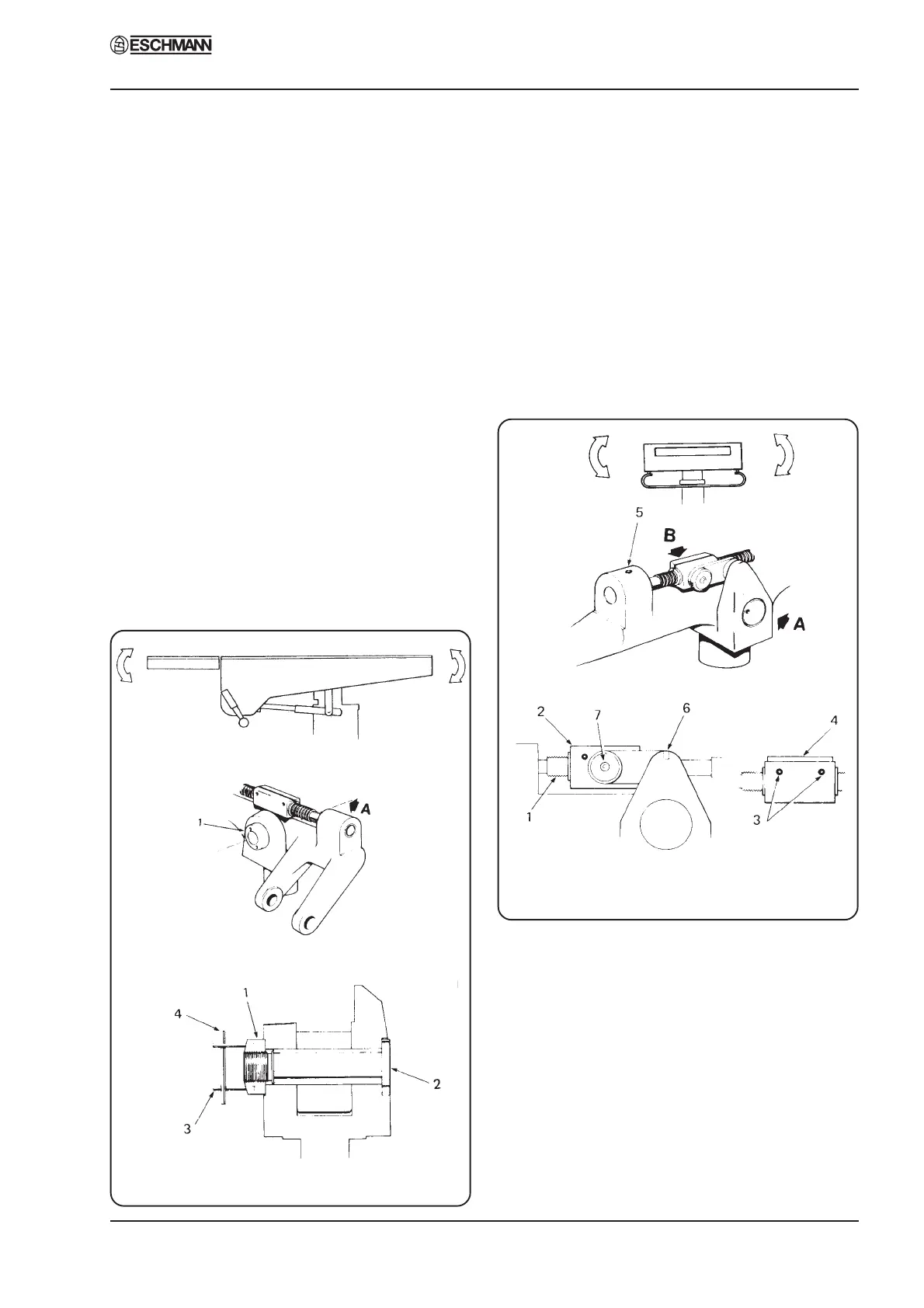

Hinge pin and nut

4.14 Pull table top as shown in Fig. 7 to check

for excessive play in the direction of the arrows.

If there is excessive play present refer to Fig. 7

and check to see if hinge nut (1) and bolt (2) are

loose. If so, * tighten hinge nut (1) against hinge

bolt (2) sufficiently to take up the slackness. To

do this, Eschmann recommend using two short

lengths of 3/16 in. diameter round bar (3) inserted

in the nut sockets, as illustrated in Fig. 7 and

applying an improvised tommy bar (4) to turn the

nut.

*Note: This could also indicate play in

Trendelenburg gear. If this is the case the complete

Trendelenburg screw assembly must be replaced.

For adjustment, see sections 4.16-4.18.

Sectional view in direction ‘A’

Fig. 7 Hinge pin and nut adjustment

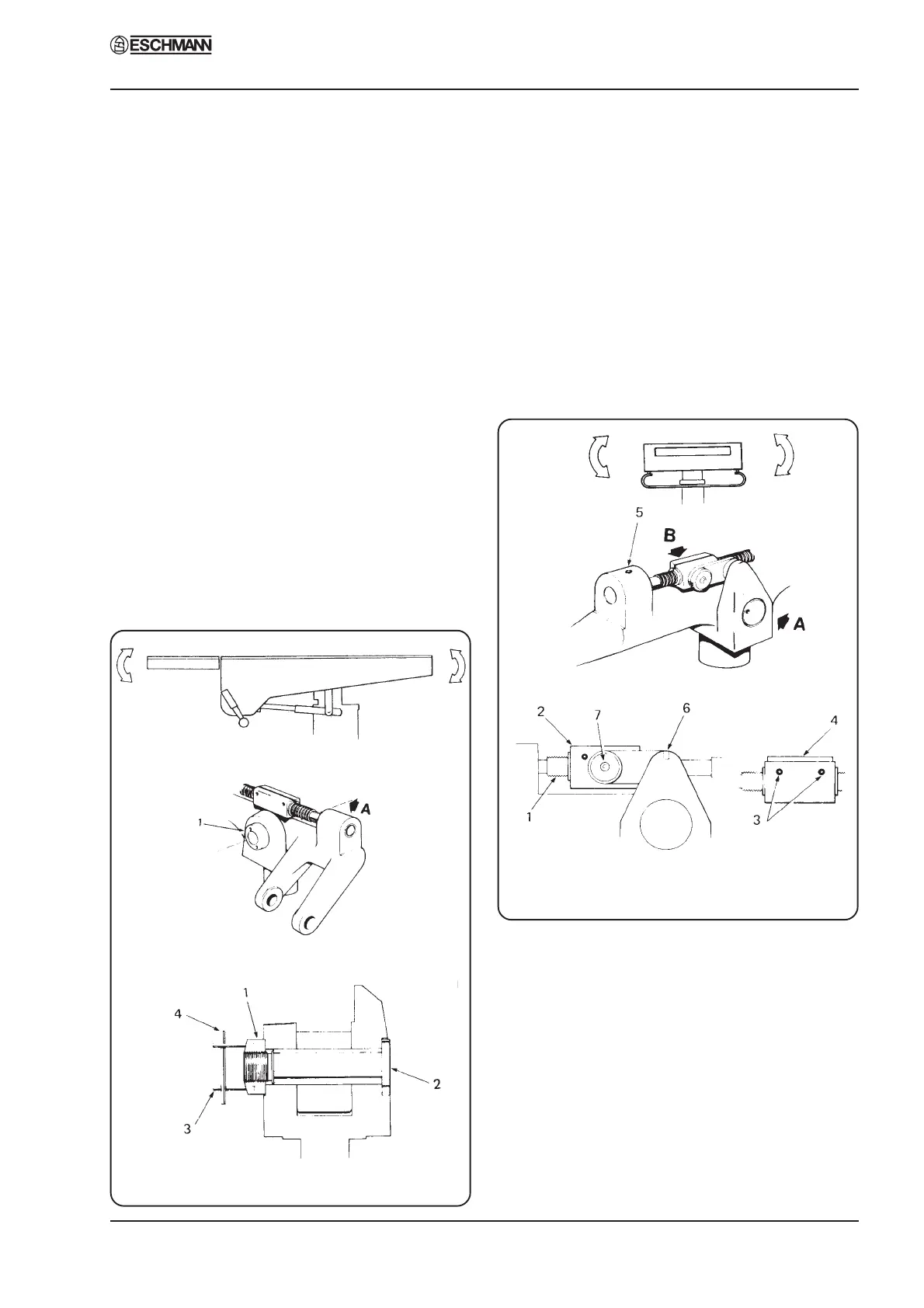

Lateral screw and nut

4.15 Place table top in reverse Trendelenburg

position, then select Lateral Tilt and operate

control handle to test movement is satisfactory.

Pull as shown in Fig. 8. If undue play is suspected

refer to Fig.8 and proceed as follows:

i Check secureness of link pivot set screws

(6) and (7).

ii Check secureness of grub screw on yoke (5)

which locks lateral screw bearing.

CAUTION: Do not over-tighten.

Detail ‘A’ Detail ‘B’

Fig 8 Lateral screw and nut adjustment

iii Finger testing at the point where the lateral

screw (1) passes through the nut (2) will

establish the need for the nut adjustment.

First try tightening socket head screws (3)

on nut. If excessive play is still present,

shim removal will be necessary. Proceed as

follows:

(a) Unfasten socket head screws (3) on nut

and extract shim pack (4).

(b) Remove shims (0.002 in thickness per

shim, approx.) one at a time until play

is just taken up on re-tightening.

Loading...

Loading...