MR & MRS OPERATION TABLES

Page 16 of 29 T-SM5f

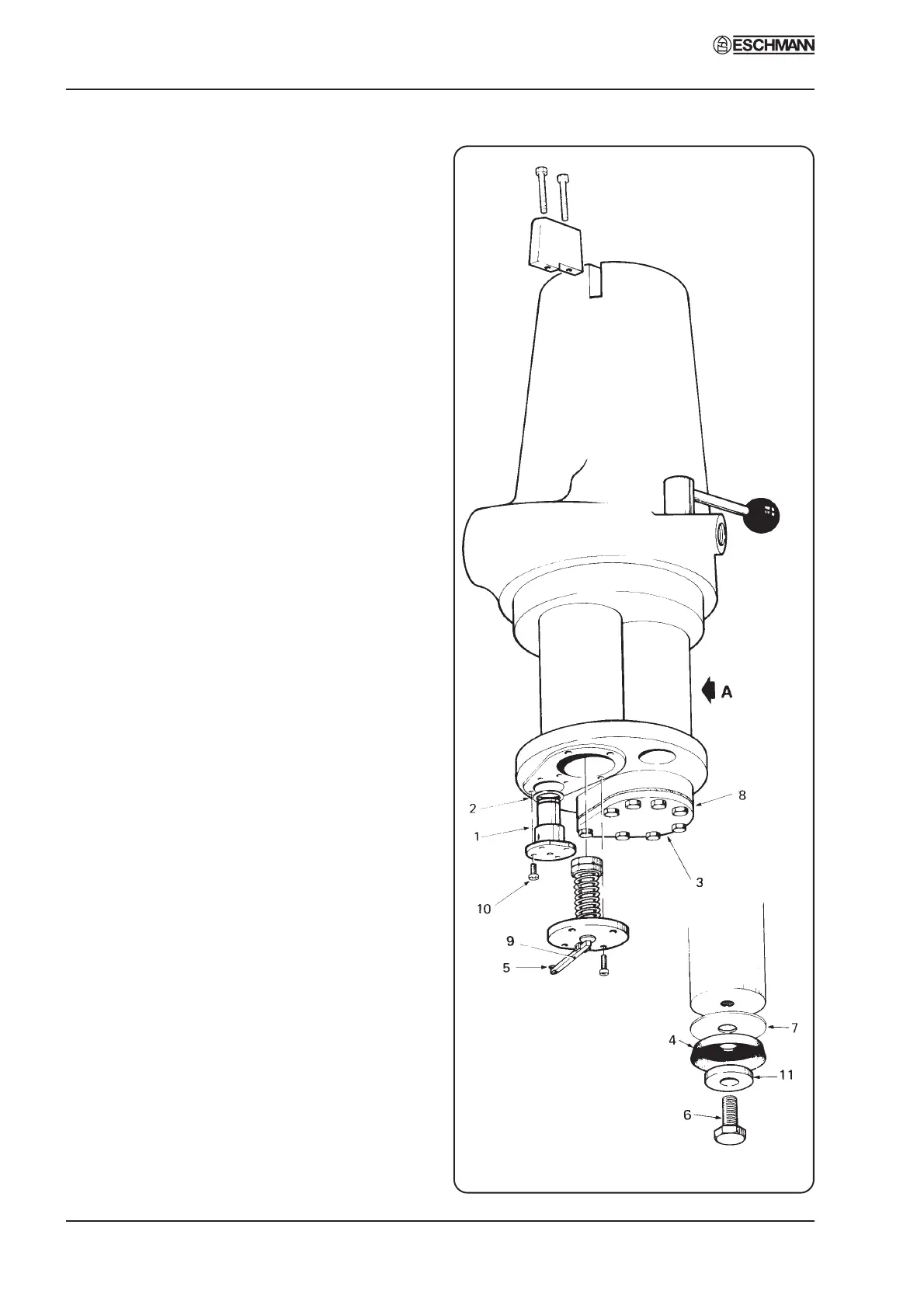

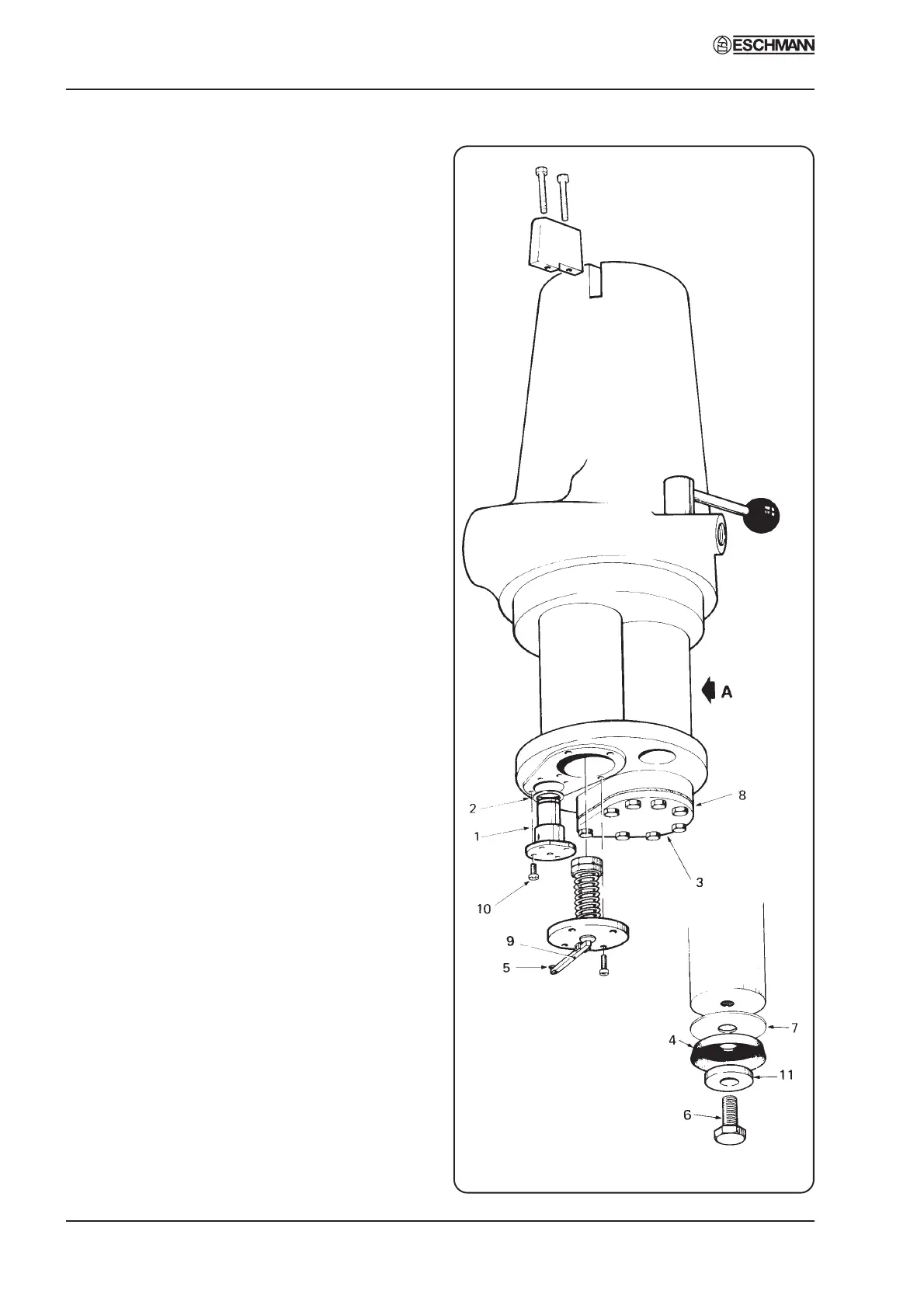

Fig. 13 Hydraulic cylinder assembly

Part 4

control handle in position with the three

screws when adjustment is correct.

ii Check the operation of the gas spring and

look for any signs of leakage. Replace the

gas spring (see section 4.59) if performance

is poor or there are signs of leakage. (Note

the Warnings and Cautions regarding gas

springs between sections 4.20 and 4.21).

iii Lubricate all moving parts using part number

670010.

iv On completion of routine checks on control

arm replace cover and check all functions.

Emergency operation - early MRS table only

4.22 This section only refers to tables with cable

operated control arms (i.e. pre Serial Number

1025). Refer to the latest version of the

Instructions for Use, Publication No. T-IM18 and

place the table in emergency operation. Check that,

with the emergency gear lever in the three

alternative positions, the table top will move in

the corresponding directions by use of the main

control handle.

Head/leg section and catches

4.23 Proceed as follows for old style sections

without gas spring supports, for sections with gas

springs refer to section 4.24.

Note: Gas spring supports were not fitted to head

sections of tables pre Serial Number 1026 for

MRS and pre Serial Number 676 for MR, or leg

sections of tables pre Serial Number 1017 for

MRS and pre Serial Number 315 for MR. Tables

with these Serial Numbers or later have gas spring

supports.

i Clean out any collected debris from the

recesses of the locking and guide pin push

button catches (4, Fig. 17) in the trunk

sections of the table. Refer to section 4.49 to

4.52 and dismantle each push button check

each component for damage or wear

replacing as necessary, Check spring-loaded

nylon plungers (2, Fig. 17) for smooth action.

Clean and lubricate the catch mechanism

then reassemble (again referring to section

4.49 to 4.52.) and test.

ii Lubricate rack and fine adjustment

movement of head/leg section.

4. MAINTENANCE

Loading...

Loading...