MR & MRS OPERATION TABLES

Page 14 of 29 T-SM5f

Part 4

hexagon (3) on the end of the leadscrew and

turning the torque screwdriver.

iv If the leadscrew rotates before the torque

screwdriver reaches 20-25 lbf.in. the friction

collar requires adjusting as (v) below. If the

leadscrew does not rotate the friction collar

setting is correct and requires no further

adjustment and the table can be reassembled.

v Adjust the friction collar by slackening the

single grub screw (4) that locks the torque

adjuster nut (5) and removing the three

screws (6) securing the cap ring (7) located

at the rear of the gearbox housing thus

exposing the torque adjusting nut (5). Locate

spanner (tool number T2097 Part No.

759652) onto the torque adjuster nut (5) and

tighten or slacken to gain the correct setting

(i.e. the torque setting is between that given

in (iii) above but operation of the

Trendelenburg handle is not too difficult).

vi Replace the cap ring (7) and secure using the

three screws (6), lock the torque adjuster nut

(5) by tightening the single grub screw (4)

and reassemble the table.

Chair and Break screw assembly friction

collars

4.19 Should the ‘Chair and Break’ screw friction

collars ever require adjustment, the procedure is

similar to that for the Trendelenburg screw

assembly (see 4.16 to 4.18), once the ‘Chair and

Break’ screw assembly has been released from

the gear shaft. (Note that MR tables with serial

number 2099 or below have the earlier design of

screw detailed in sections 4.16 to 4.18 and tables

above 2099 have the latest design screw. All MRS

tables have the early design ‘Chair and Break’

screw).

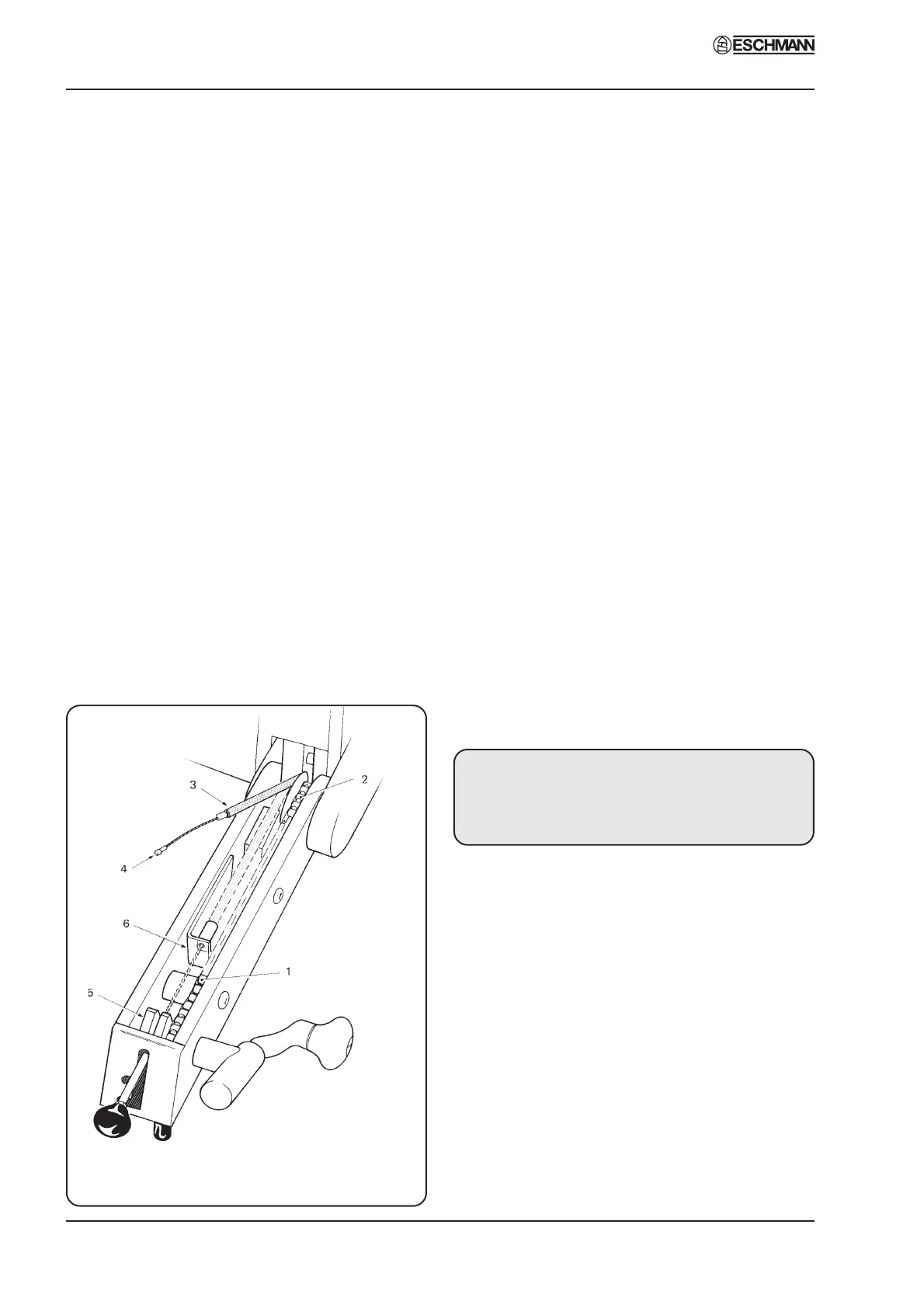

Control arm (cable type) - MRS only

4.20 The control arm of early tables were cable

operated and were fitted to tables with Serial

Number 1023 or earlier. Refer to Fig. 11 and

remove the control arm cover, then:

i Check chain links (1)

ii Check gears and keys (2)

iii Ensure lubrication of cable (3)

iv Check cable bends and cable nipples (4)

(also see Fig. 15).

Control arm (gas spring type) - MRS only

WARNING

Gas springs are filled with

high pressure gas.

DO NOT ATTEMPT TO OPEN THEM

CAUTION

Gas springs MUST NOT be

additionally lubricated.

4.21 Gas spring operated control arms have been

fitted to tables from Serial Number 1024 onwards.

Remove the extended head end control arm cover

(see Fig. 20) and carry out the following

procedures to ensure the correct function of the

control arm.

i Check gears and keys and that the chain

operates smoothly and is not loose. If the

chain is loose it can be adjusted by releasing

the three screws located around the main

control handle mounting plate. This plate is

eccentric and rotating it will alter the chain

tension and remove slack, lock the main

4. MAINTENANCE

Fig. 11 Control arm (early MRS table)

Loading...

Loading...