T-SM5f Page 19 of 29

MR & MRS OPERATION TABLES

Part 4

4. MAINTENANCE

completely loose then remove clamp and

ram release (see Fig. 12(d)).

iv Refer again to Fig. 14. Adjustment consists

of unscrewing, in a clockwise direction, the

two large lock nuts (4) on the end of the

release plunger (5) to allow more movement

of the ram release lever. This is in order to

cause the ball of the ball valve to be lifted

further and so release the table ram. (For a

more detailed explanation of the hydraulic

system, refer to section 4.60 and 4.61).

Note:This adjustment can only be made on a trial

and error basis. Each time an adjustment is

made the ram release must be refitted into

the cylinder and the pump lever tried and

held to ascertain whether the release screw

on the lever projects too far into the ball

valve, or still not enough. Care must be

taken to adjust this correctly as strain will

occur either side of the normal. As a guide,

the normal setting is 1/16in between release

screw and ball valve housing (approximately

the thickness of an engineer’s steel ruler).

v When the correct adjustment has been made,

lift the cylinder and table top bodily and

guide the cylinder back into the well of the

base. DO NOT ALLOW THE CYLINDER

TO DROP INTO THE BASE. When the

table is in an upright position and before

lowering it into the base, refit the locking

lever. This will prevent the escape of oil

from the cylinder. The table top should now

raise and lower normally.

Note:If it is found that the driving pin of the pump

pedal has been bent - too badly for any

adjustment - a new pump lever must be

fitted.

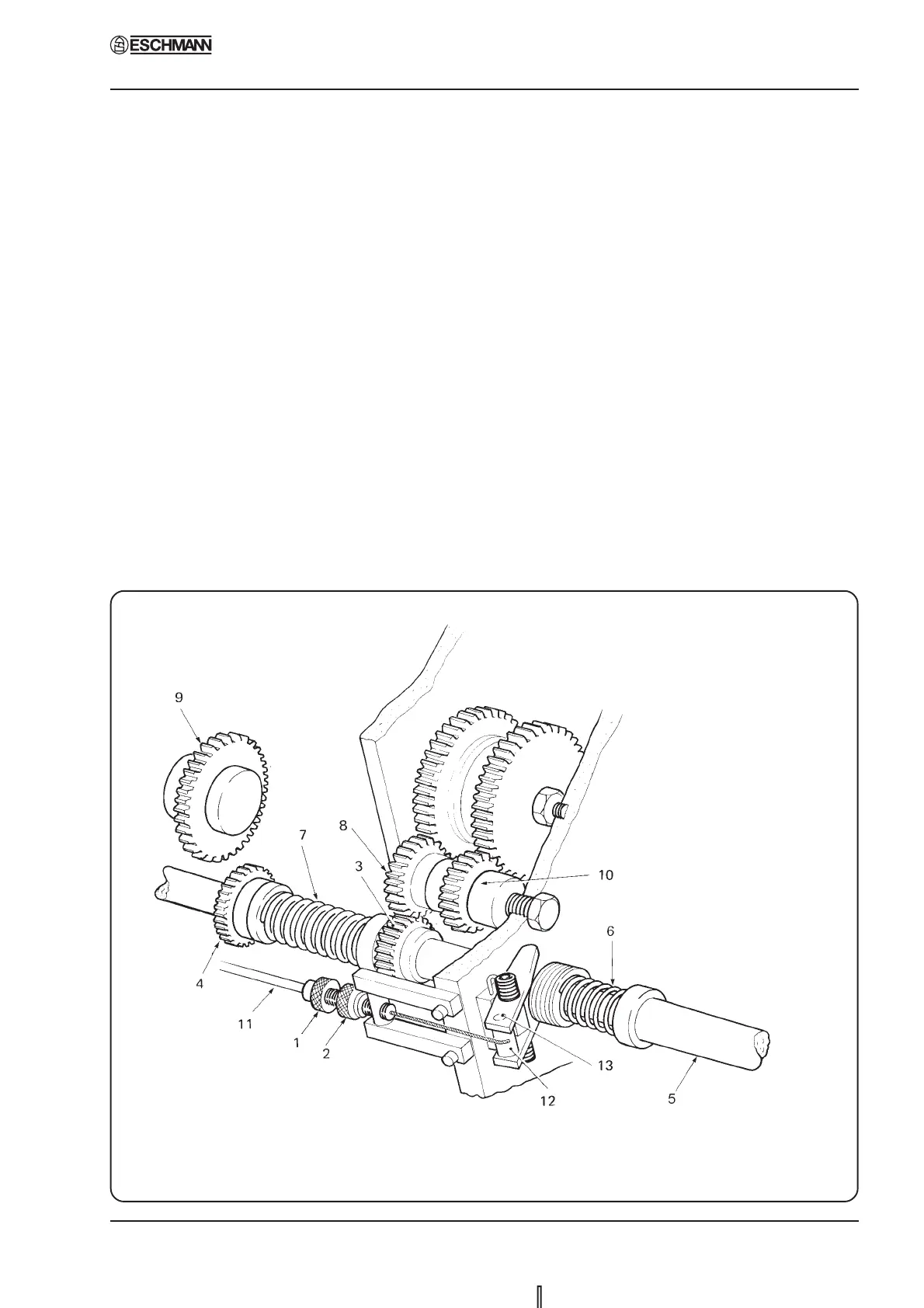

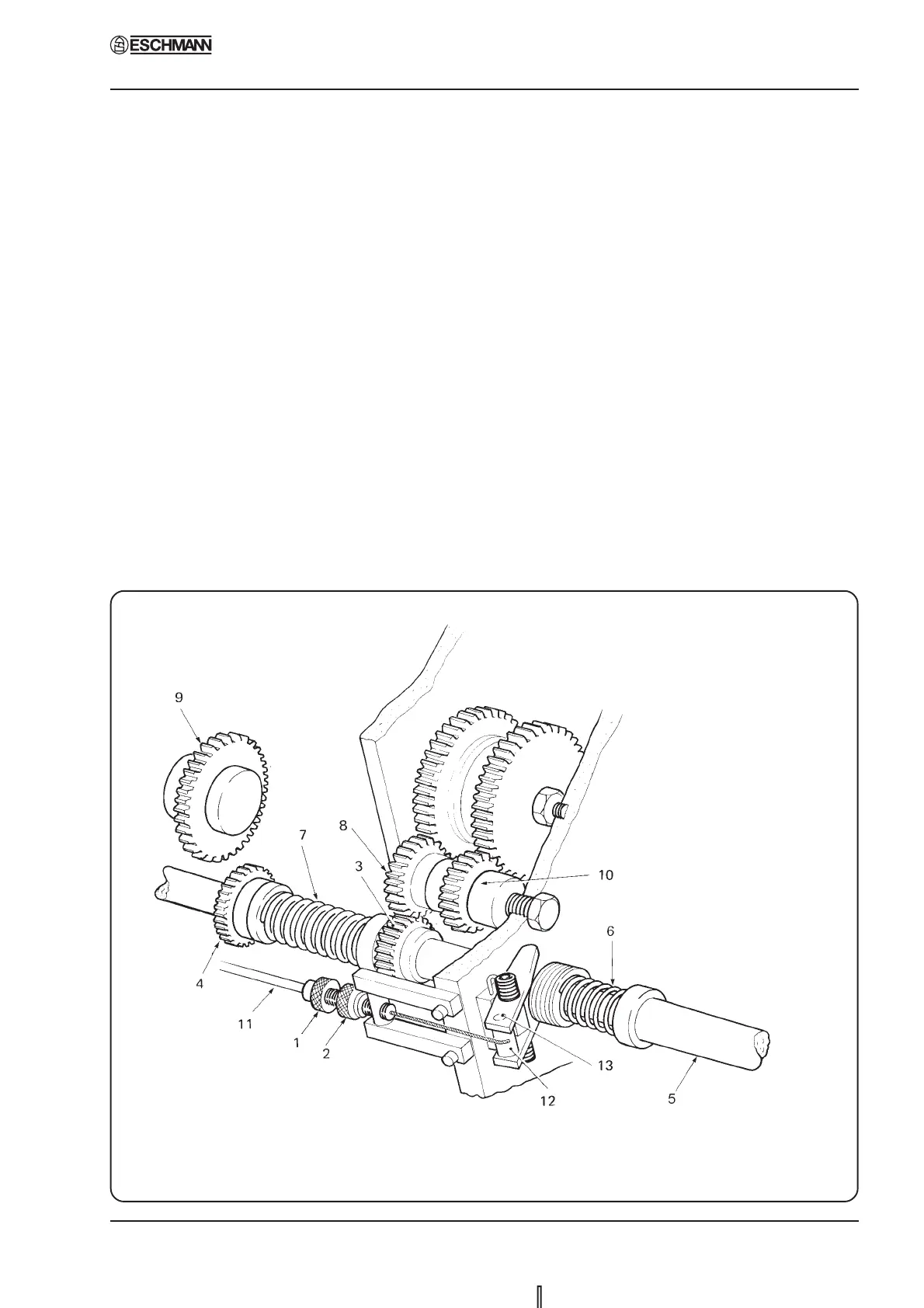

Fig. 15 Control arm cable adjustment/replacement - MRS table pre Serial No. 1024

Loading...

Loading...