MR & MRS OPERATION TABLES

Page 24 of 29 T-SM5f

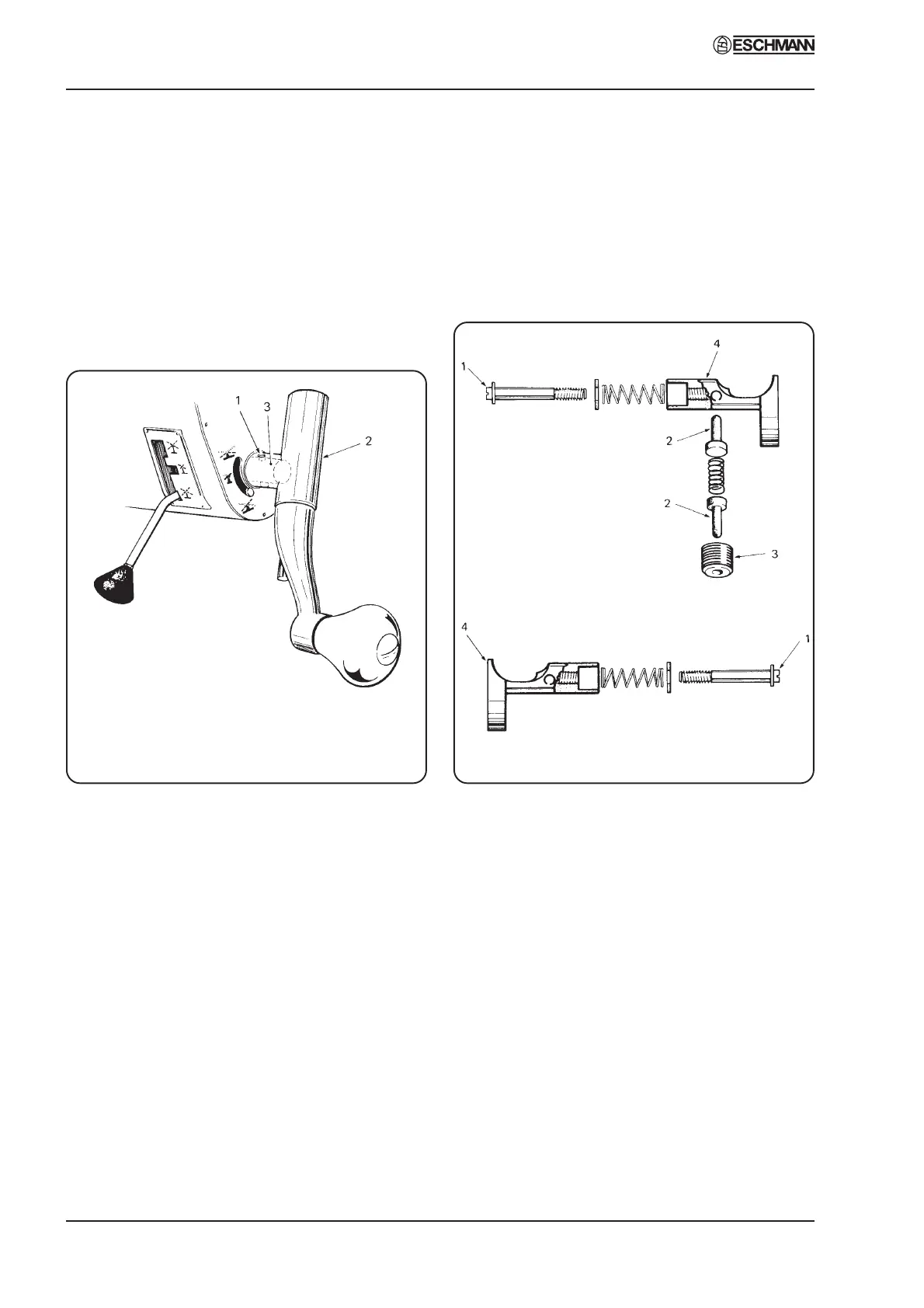

vi Complete drilling through handle, using a

wooden block for the drill to break into -

hence protecting the plating on the handle.

vii Use a tapered reamer to shape out the holes

for the taper pin. Fit new taper pin (1)

ensuring that it is inserted through the aligned

holes the correct way round.

viii Remove the distance piece from the selector

shaft (see ‘ii’ above)

Fig. 16 Replacing a control handle

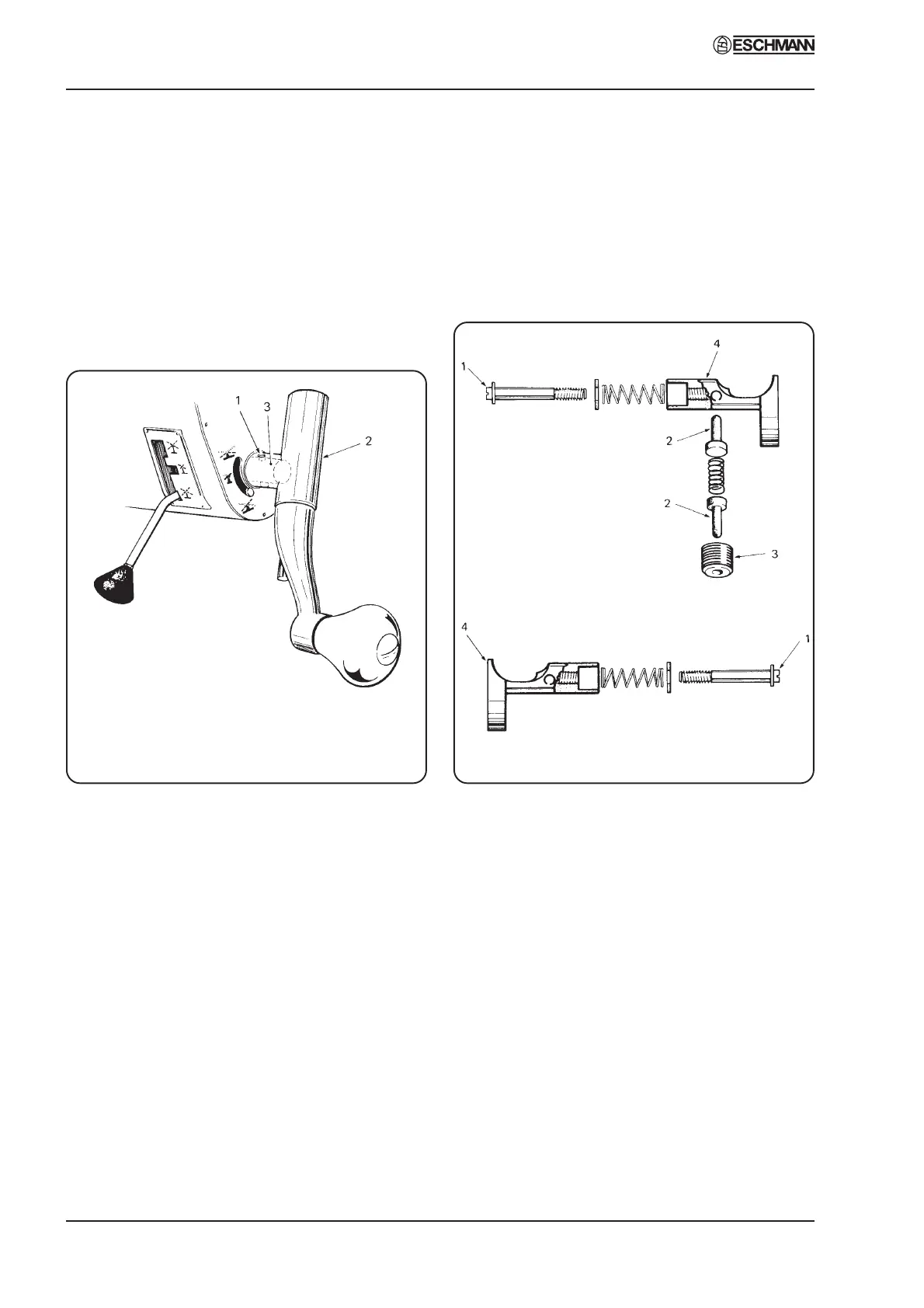

Replace push-button catches - head / leg section

4.48 Should it be necessary to gain access to the

push-button catches for cleaning, lubrication or

replacement, first remove the appropriate section

(head or leg section) and apply a screwdriver to

the slotted end of the threaded spindle of the catch

(1, Fig 17). The catch spindles at the lower trunk

end of the table are readily visible (at the end of

the section underneath the radiographic top) but

to gain access to those at the upper trunk end it is

necessary to detach the radiographic top of the

upper trunk section by removing the socket head

screws.

4.49 The right hand push-button ‘A’ catch

operates in conjunction with a spring loaded

plunger (2, Fig. 17) which, in turn, operates to

(A)

(B)

retain the push-button in the ‘release’ position if the

button is pressed with the head or leg section in

position.

4.50 The left hand push-button ‘B’ catch has no

retaining plunger and must be pressed in

continuously while the head/leg section (or table

accessory, where appropriate) is being withdrawn.

Fig. 17 Catch mechanism for leg section

4.51 Ensure that the spring loaded plunger

(2, Fig. 17) referred to in section 4.49 moves freely

in its socket. If the plunger has become damaged

or distorted such as to impair free movement, it

should be replaced. To remove plunger, unscrew

threaded bush (3, Fig. 17).

4.52 To remove a faulty latch, unscrew threaded

spindle (1, Fig.17) completely and lift away push

button/latch assembly (4, Fig.17). If the latch has

scored the attachment pins of head/leg section the

complete push-button/latch should be replaced.

Repair any scoring on attachment pins with a fine

file and/or crocus cloth before placing in service

again. It is advised that setting tool number T1612

Part No. 759579 is used when finally adjusting

push buttons as follows:

i Push setting tool T1612 into guide pin hole

up to the edge of the groove.

Loading...

Loading...