MR & MRS OPERATION TABLES

Page 8 of 29 T-SM5f

4. MAINTENANCE

GENERAL

4.1 The information provided in this Service

Manual falls into four categories:

♦ Cleaning, Disinfection, Care and Storage.

♦ Periodic lubrication, checks and adjustments

♦ Fault diagnosis and remedies

♦ Removal and installation of components

CLEANING, DISINFECTION, CARE AND

STORAGE

4.2 For Cleaning, Disinfection, Care and

Storage instructions refer to Section 8 of the

Instructions for Use (Publication T-IM18, also see

section 1.3).

PERIODIC LUBRICATION, CHECKS

AND ADJUSTMENTS

Base Components

4.3 In order to carry out maintenance procedures

to the table base, it is necessary to tilt the table on

its side and expose the underside of the base.

Proceed as follows:

i Remove the head and leg section in the

normal manner (see Instruction for Use,

Publication T-IM18).

ii Raise the table top to its maximum height.

iii Place an anaesthetist’s stool, or similar strong

support, alongside the table.

iv Place the brake pedal in the ‘castor’ position.

v Stand on the same side of the table as the

support but with the pump lever on the

opposite side. Push the table away about

30 cm and then pull it back. This ensures

that all the castors are pointing away from

the operator. Two people on the same side of

the table as the support (one at each end) can

now each place a foot against the base and

lever the table over gently, lowering it onto

the support.

Castors and wheels

4.4. Clean each castor (see Fig. 5) and wheel free

of debris, then lubricate the castor and wheel ball

races with a light machine oil (or WD40 aerosol

lubricant).

Part 4

Brakes and brake mechanism

4.5. Check the action of the brake mechanism

(see Fig. 5) and also check for wear on the brake

pads, broken brake pinion or quadrant teeth, play

in the quadrant taper pins and adjustment between

quadrant, roller and eccentric pin. Check stop

screws for wear. To replace quadrant see section

4.44; to replace quadrant pinion, see section 4.45.

4.6 Fit new brake pads where necessary,

referring to section 4.43.

Hydraulic Cylinder

4.7 Raise the table top to its maximum height,

then depress the height adjustment (hydraulic

pump) pedal fully and check for smoothness and

rate of descent.

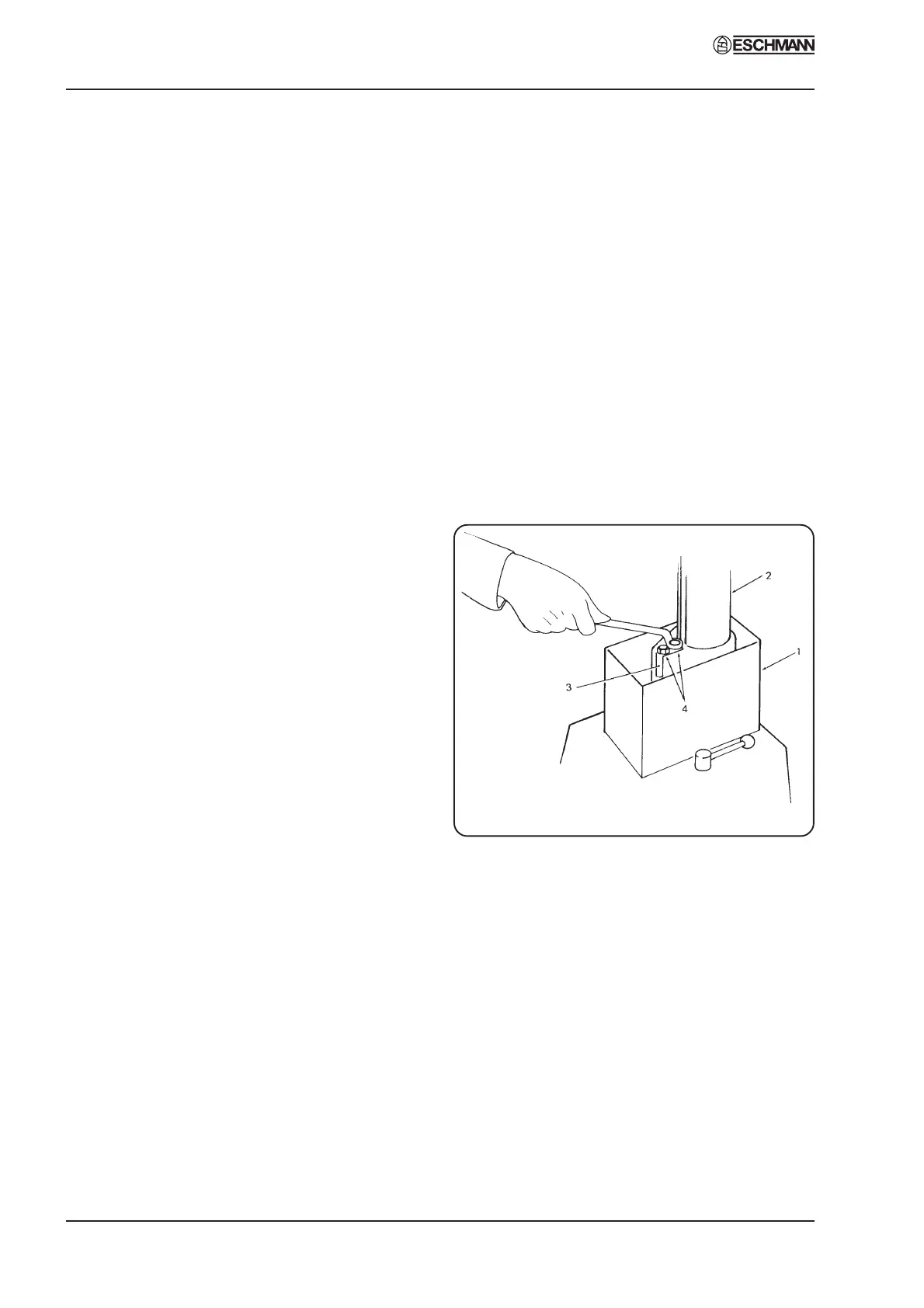

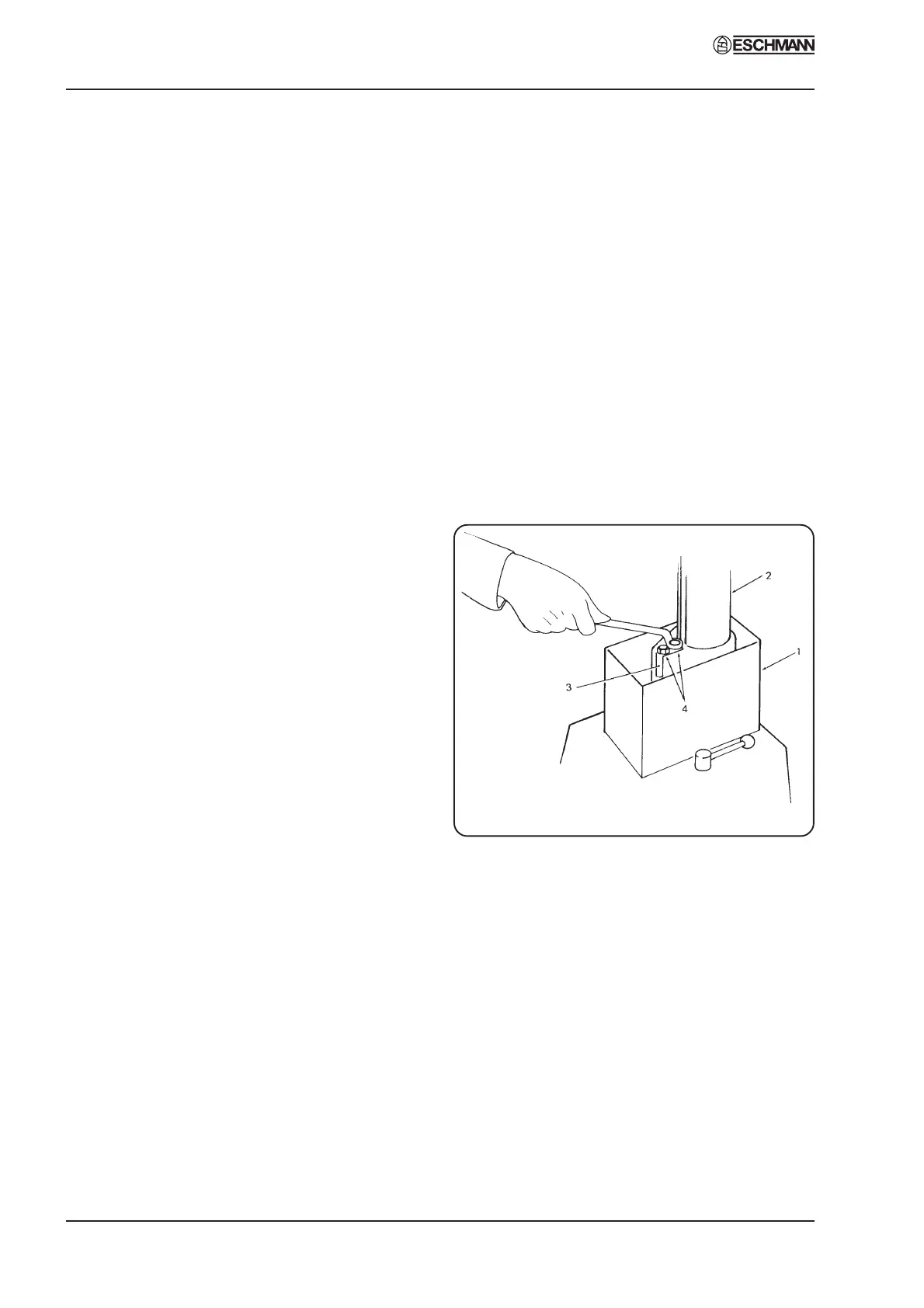

Fig. 4 Ram key adjustment

4.8 Raise the table top to its maximum height

again and release the ram cover securing screws

at the top. Refer to Fig. 4 and lower the 3-section

telescopic cover (1) to expose the ram (2) and ram

key (3).

4.9 Remove the ram key, clean out keyway and

refit key.

4.10 Examine ram surface for rust and, if present,

clean off with fine emery cloth. (Note: Later rams

have a black surface coating do not confuse this

with rust and attempt to remove it). Lubricate

exposed surface of ram. Seal the top of the cylinder

with cloth wound round the ram to prevent damage

if using emery cloth.

Loading...

Loading...