303

TRIM AND TILT

ELECTRICAL CIRCUIT TESTS

14

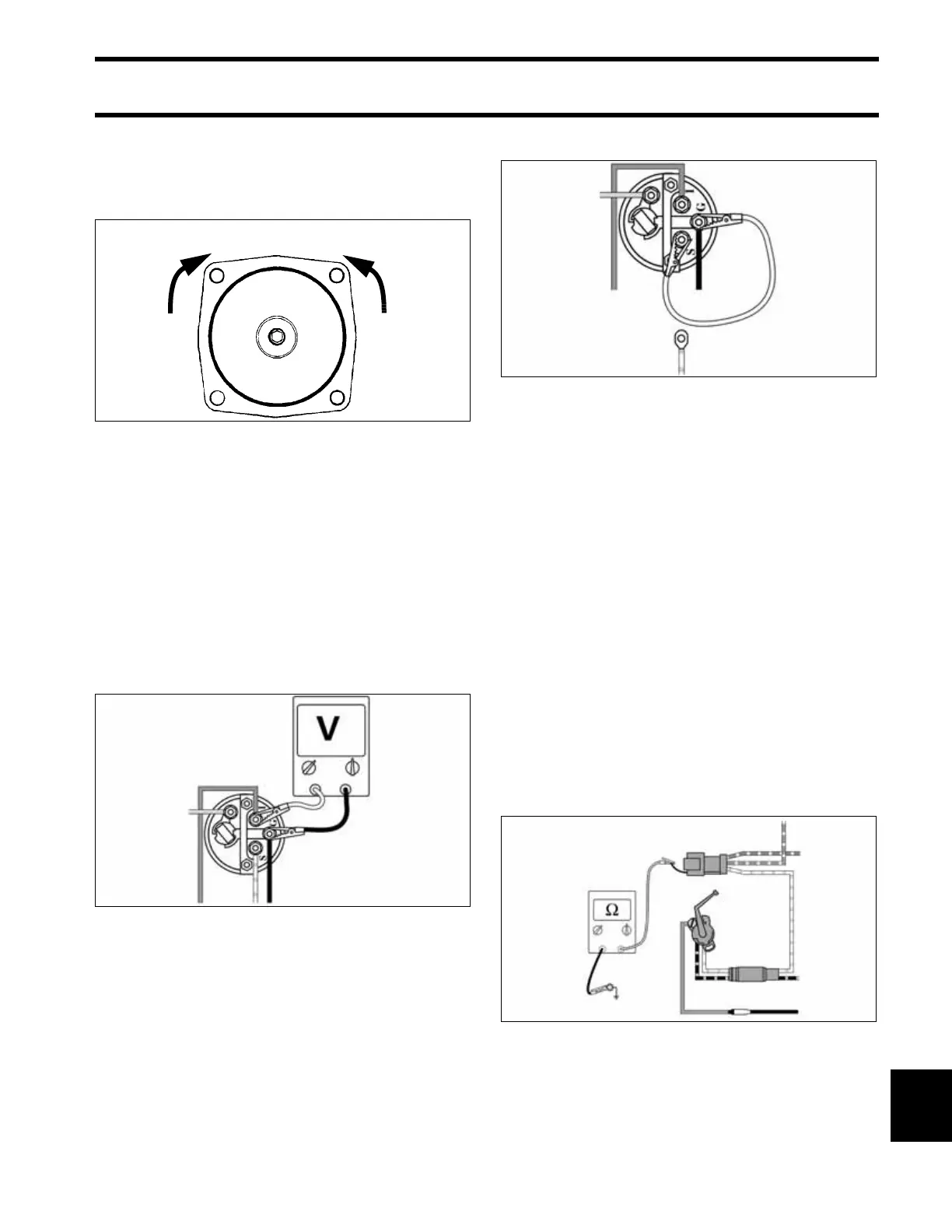

The motor shaft must rotate counterclockwise, as

viewed from the pump end, when positive (+) is

applied to the green lead, and negative (–) is

applied to the blue lead.

If test results vary, replace the motor.

Trim Gauge Test

STEP 1

Turn key switch ON. Using a voltmeter, check for

voltage between the trim gauge “I” and “G” termi-

nals.

• If no voltage, check condition of instrument har-

ness, key switch, and engine 20 A fuse.

• If voltage is shown, go to STEP 2.

STEP 2

Remove the white/tan lead from the trim gauge

“S” terminal. With key switch ON, gauge should

indicate full-trim DOWN position. Now connect a

jumper wire between terminals “S” and “G.”

Gauge should indicate full-trim UP position.

• If results are different, replace the trim gauge.

• If results agree, refer to Trim Sender Test.

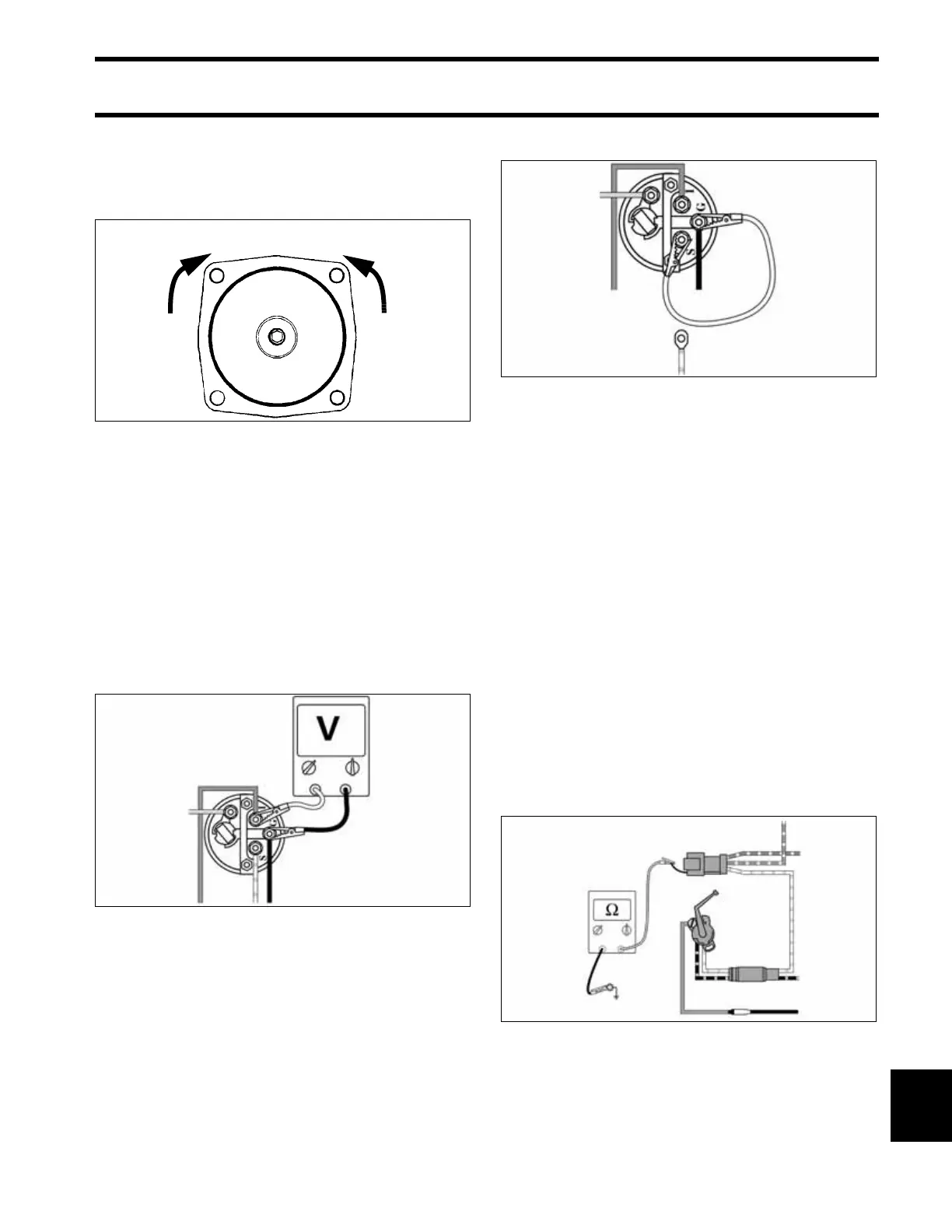

Trim Sender Test

IMPORTANT: To avoid immediate meter dam-

age, never apply an ohmmeter to an electrical cir-

cuit where voltage is present.

Disconnect the 3-pin Deutsch connector between

the instrument harness and engine trim harness.

Connect an ohmmeter between the white/tan

wire, terminal “C,” of the engine harness and a

clean engine ground.

With the outboard fully DOWN, meter must show

a reading above 80 ohms.

With the outboard fully UP, meter must show a

reading below 10 ohms.

• If results agree, refer to Trim Gauge Test on

p. 303.

• If results are different, replace trim sender.

DR4238r

DRC6245

Green lead (+)

Blue lead (-)

Blue lead (+)

Green lead (-)

DRC6246A

DRC6247

Loading...

Loading...