149

ELECTRICAL AND IGNITION

CONNECTOR SERVICING

7

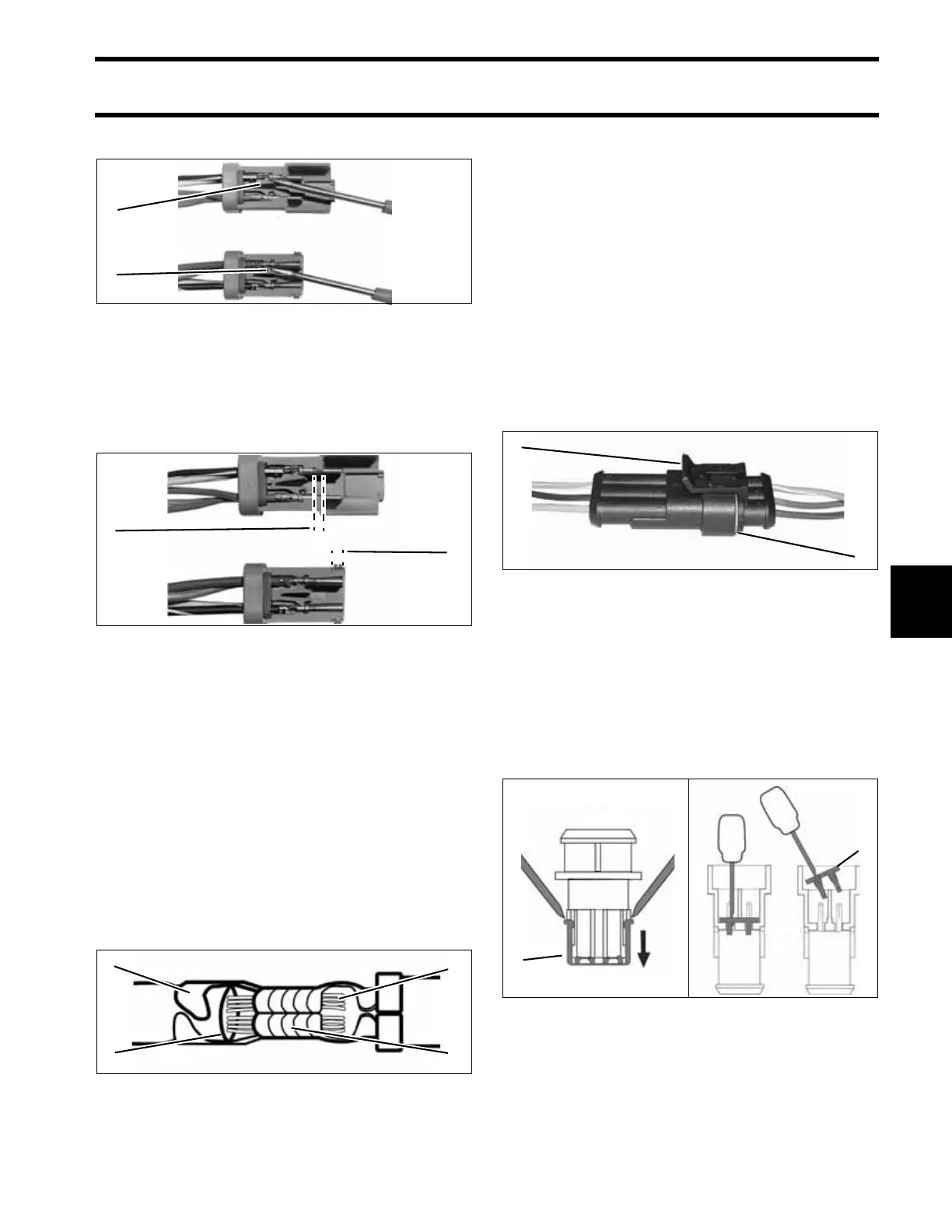

Release terminal latch and gently pull on wire.

Terminal Installation

Push terminal through seal until it locks into place.

Fill connector with Electrical Grease to 1/32 in.

(0.8 mm) below ledge or end of plug.

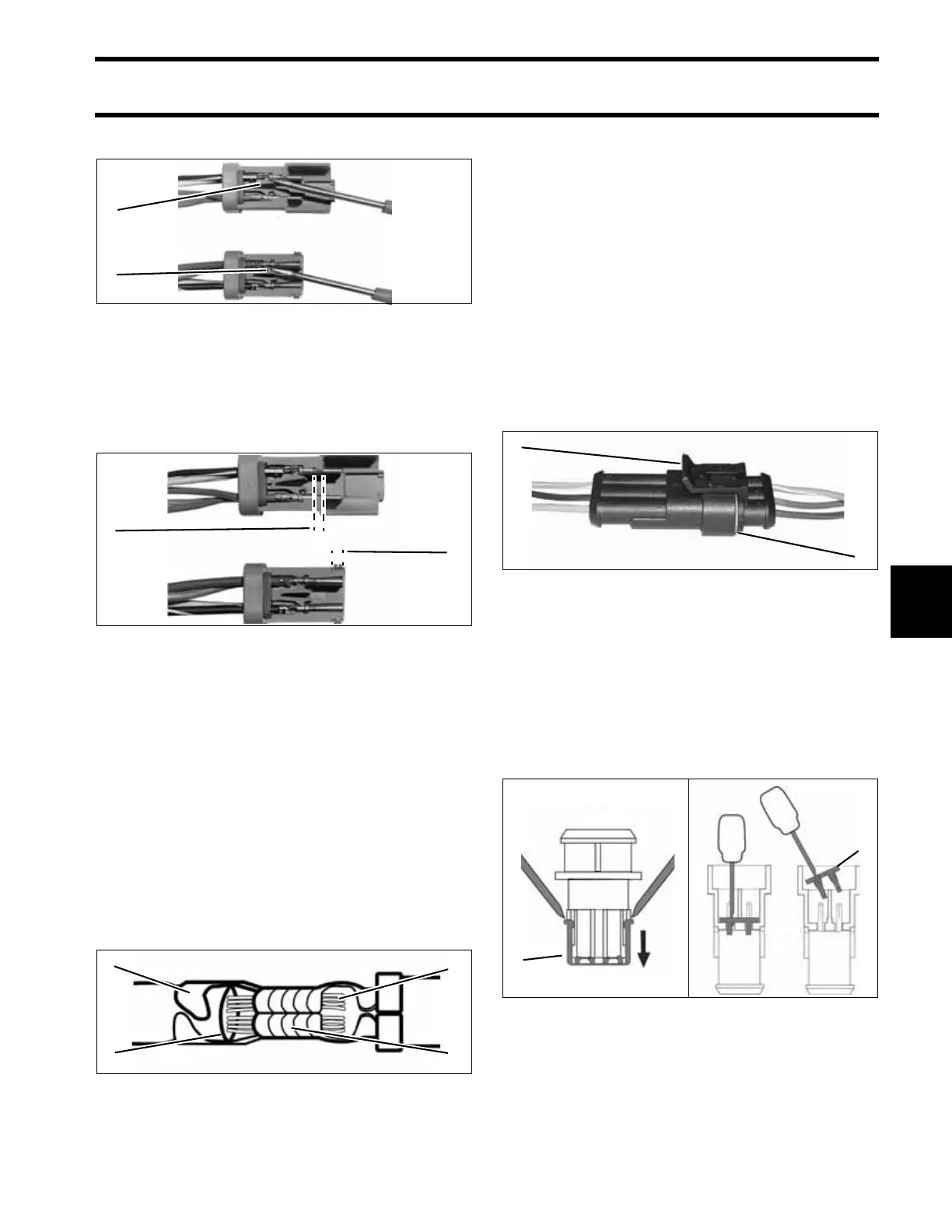

Push wedge in until latched. Wedge in 2-pin

receptacle is not symmetrical; position latch shoul-

ders next to terminals.

Crimping Terminals

Strip insulation back 3/16 in. (5 mm). Place termi-

nal in 18-gauge notch of Crimping Pliers,

P/N 322696. Position end of wire strands in termi-

nal past wire crimp area, and position end of insu-

lation past insulation crimp area. Capture all wire

strands in crimp; leave no loose strands. Crimp

wire securely. Do not solder. Crimp insulation in

14/16-gauge notch of crimping pliers.

AMP Connectors

IMPORTANT: Always use the appropriate

meter test probes and adapters when testing com-

ponents fitted with these terminals. Electrical

grease is NOT used on AMP connectors.

SUPERSEAL

†

1.5

Disconnect

Lift latch. Pull connectors apart.

Connect

Confirm the seal is in place. Push connectors

together until latched.

Terminal Removal

Use Secondary Lock Tool, P/N 777078, to release

anti-backout device of connector housing. Next,

use Primary Lock Tool, P/N 777077, to release

locking tab of connector housing. Release locking

tab and pull on wire to remove from connector

housing.

1. Terminal latch (plug)

2. Terminal latch (receptacle)

42329

1. Ledge of plug

2. End of plug

42330

1. End of wire strands

2. Insulation crimp area

3. End of insulation

4. Wire crimp area

DRC6205

1

2

2

1

1

4

2

3

1. Latch

2. Seal

002448

1. Anti backout device, plug

2. Anti backout device, receptacle

002449

002450

2

1

2

1

Loading...

Loading...